X30

Non-deoxidized Copper (0.04%O)

Composition: Non-deoxidized copper (0.04%O).

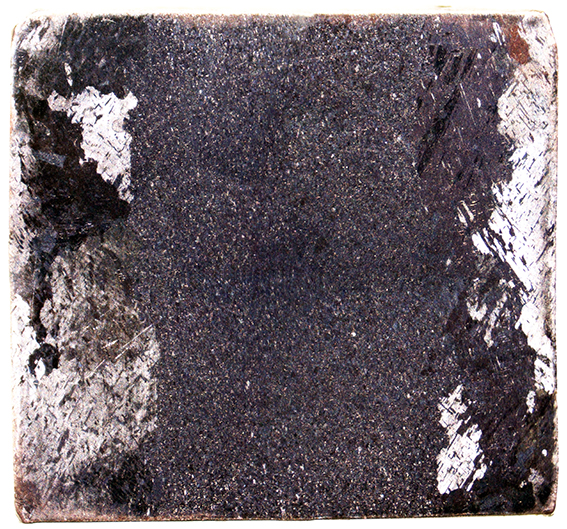

Processing: Hot extrusion.

Etching: 1 min immersion in FeCl3 alcoholic solution.

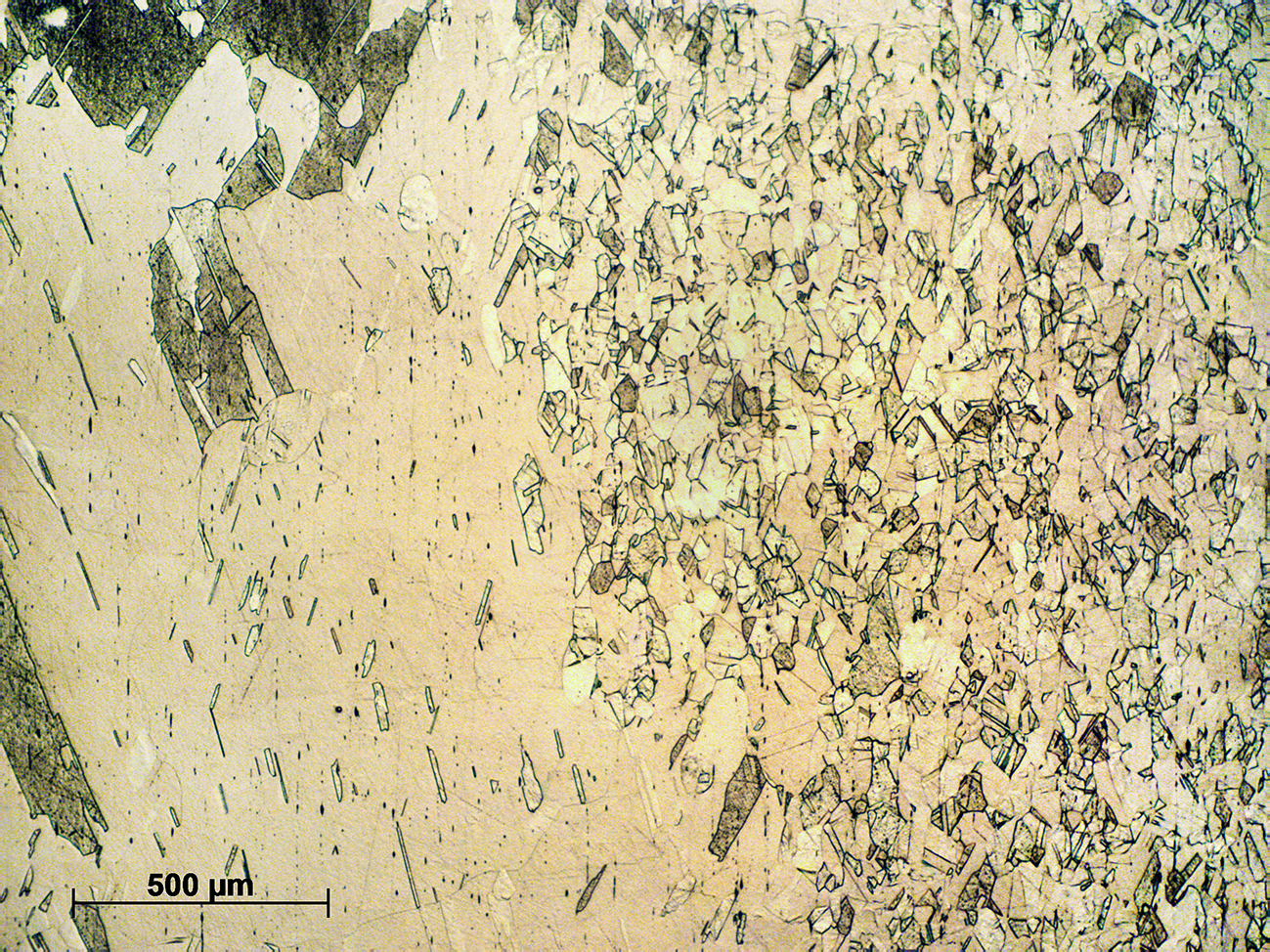

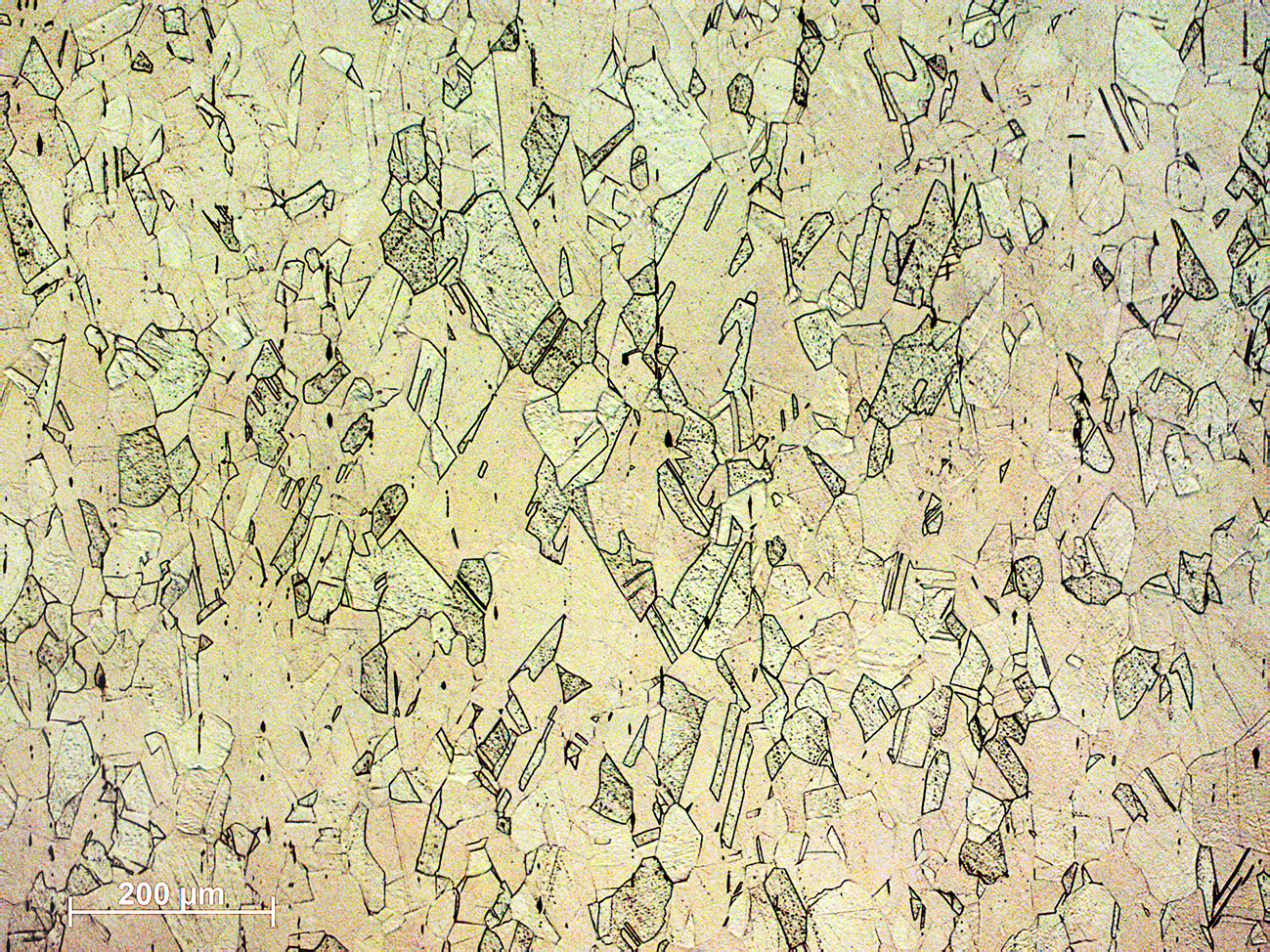

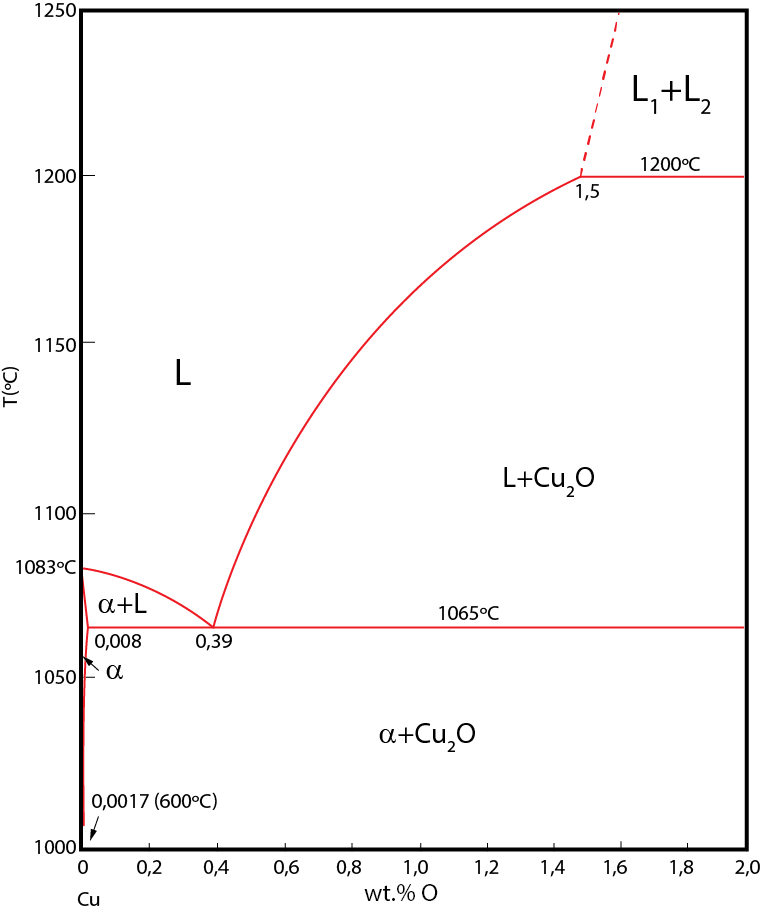

During solidification dendrites of α solid solution are formed. Then, when the liquid reaches the eutectic composition (0.39%O), an aggregate of α + Cu2O is formed in between the dendrites. This structure, consisting of 99,6% α and 0,4% de Cu2O is quite brittle. Hot extrusion deforms and breaks up the dendrites and results in recrystallization of the α phase. The result is small grains and small particles of Cu2O from the eutectic, which get aligned in the extrusion direction. These small particles can be seen very well on the unetched polished surface.

The macrograph shows an irregular distribution of grain size. Large grains are found in the periphery, whereas small grains are located in the centre of the specimen. The larger grain size in the outer rim is associated with the higher temperature in this region during the extrusion. Inclusions remain visible after etching. It is also possible to see the characteristic twins of the α phase (FCC).

Cu-O diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International