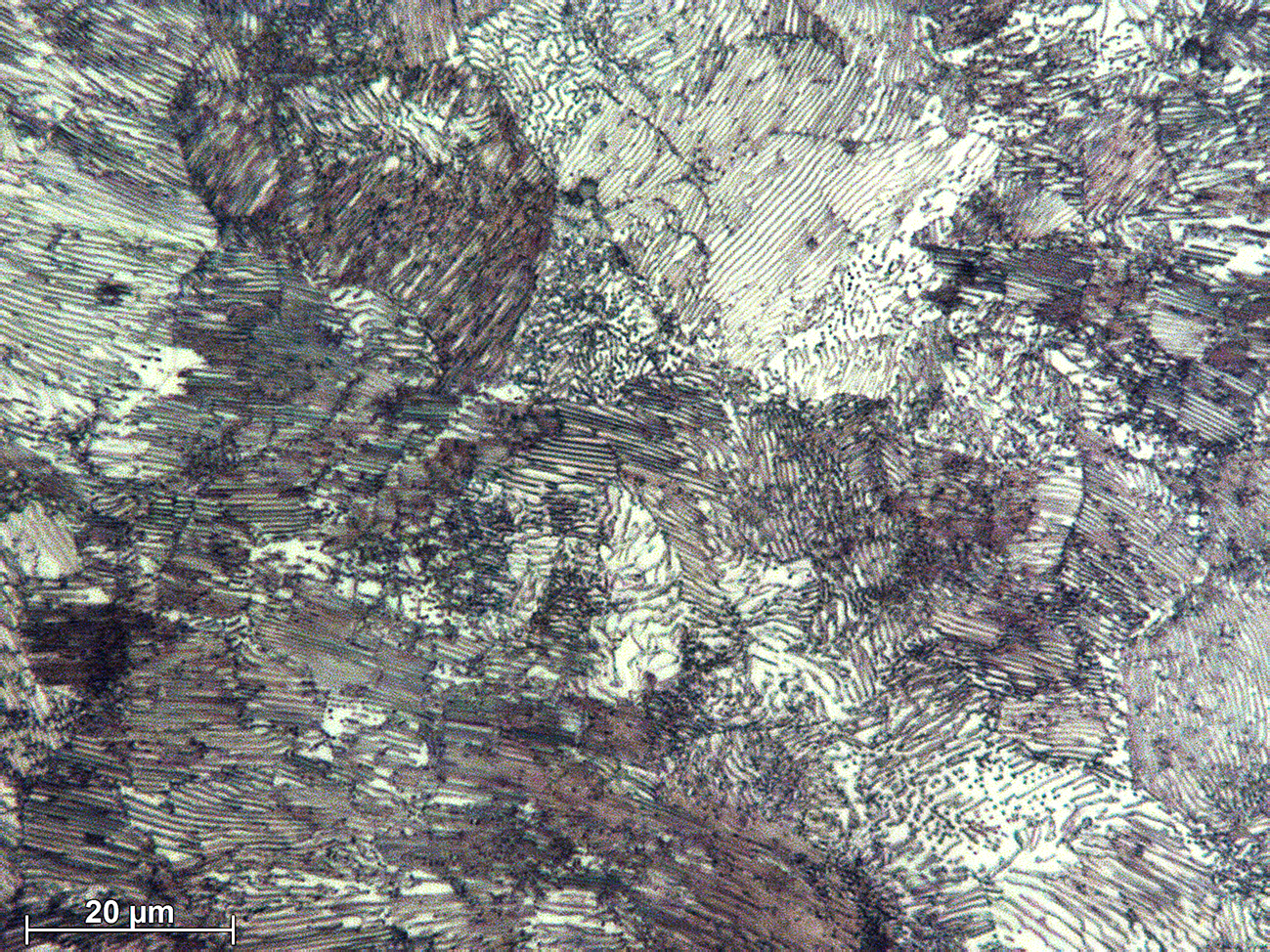

X18

Carbon steel (0.8%C) Normalized

Composition: Carbon steel (0.8%C, eutectoid).

Processing: Hot-rolled. Annealing (800ºC-1h), Air cooling.

Etching: 10-15 s immersion in 2% nital.

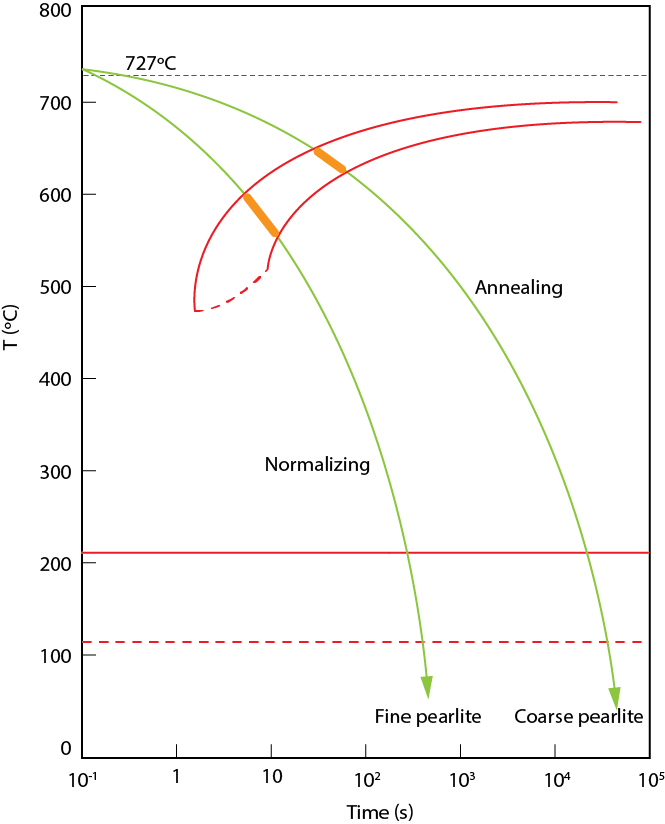

This steel has the same composition as the X17 specimen, but in this instance air cooling from the austenitic field is performed. This is known as normalizing and, as shown in the continuous cooling diagram, the cooling rate is faster than that achieved during furnace cooling (annealing). This translates into shortened time to complete the eutectoid transformation and favoured nucleation due to a higher level of undercooling. The final result is fine pearlite with lamellae of ferrite and cementite that are hardly distinguishable in the micrographs.

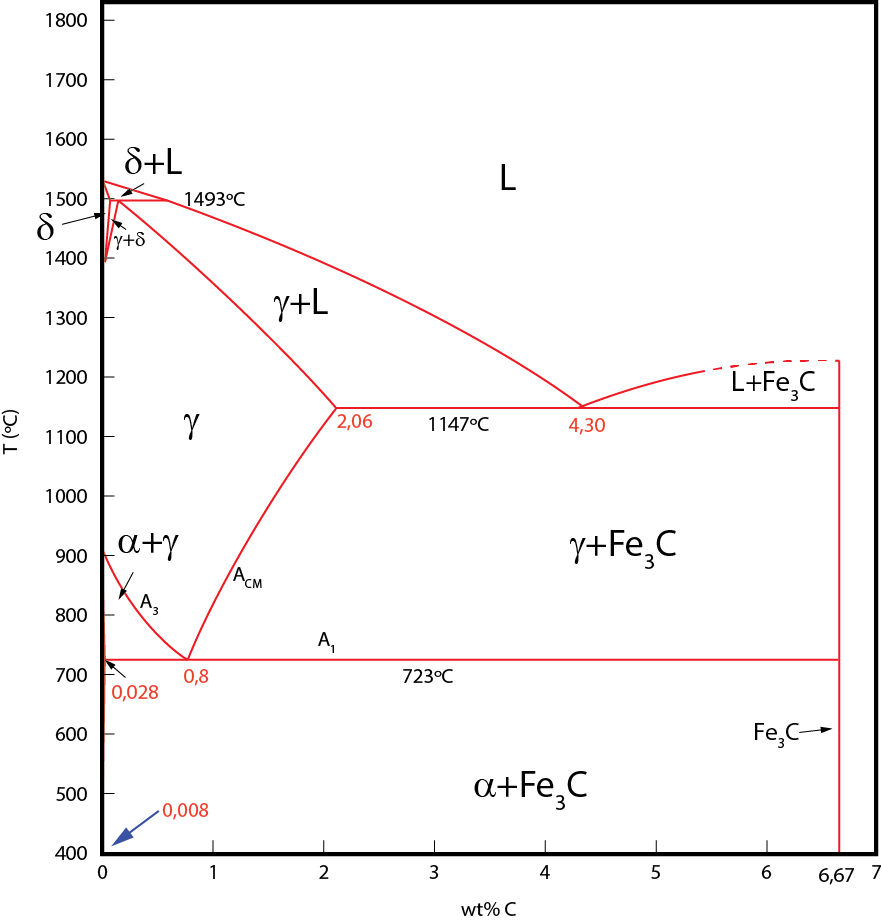

Fe-Fe3C diagram

CCT diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International