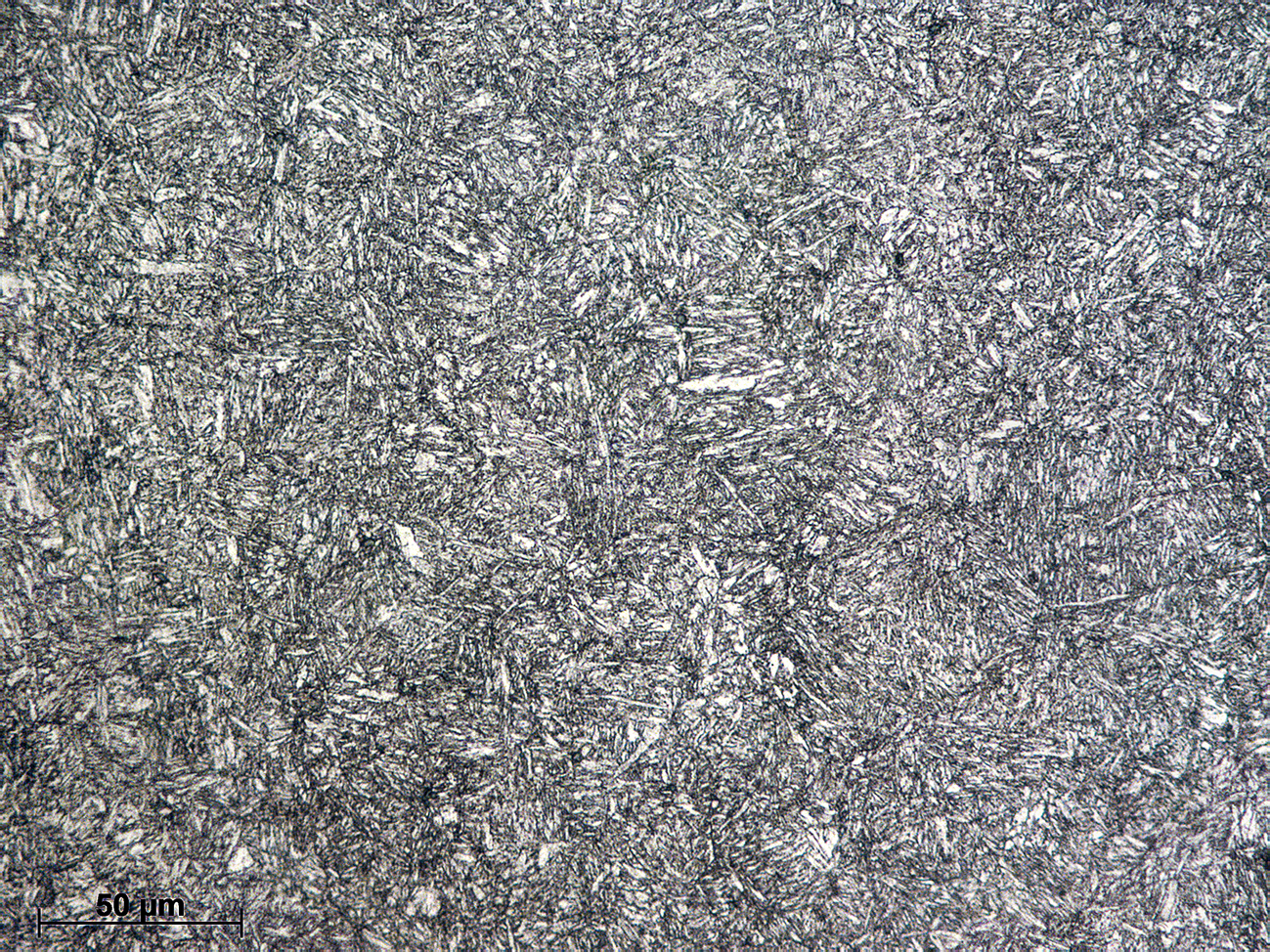

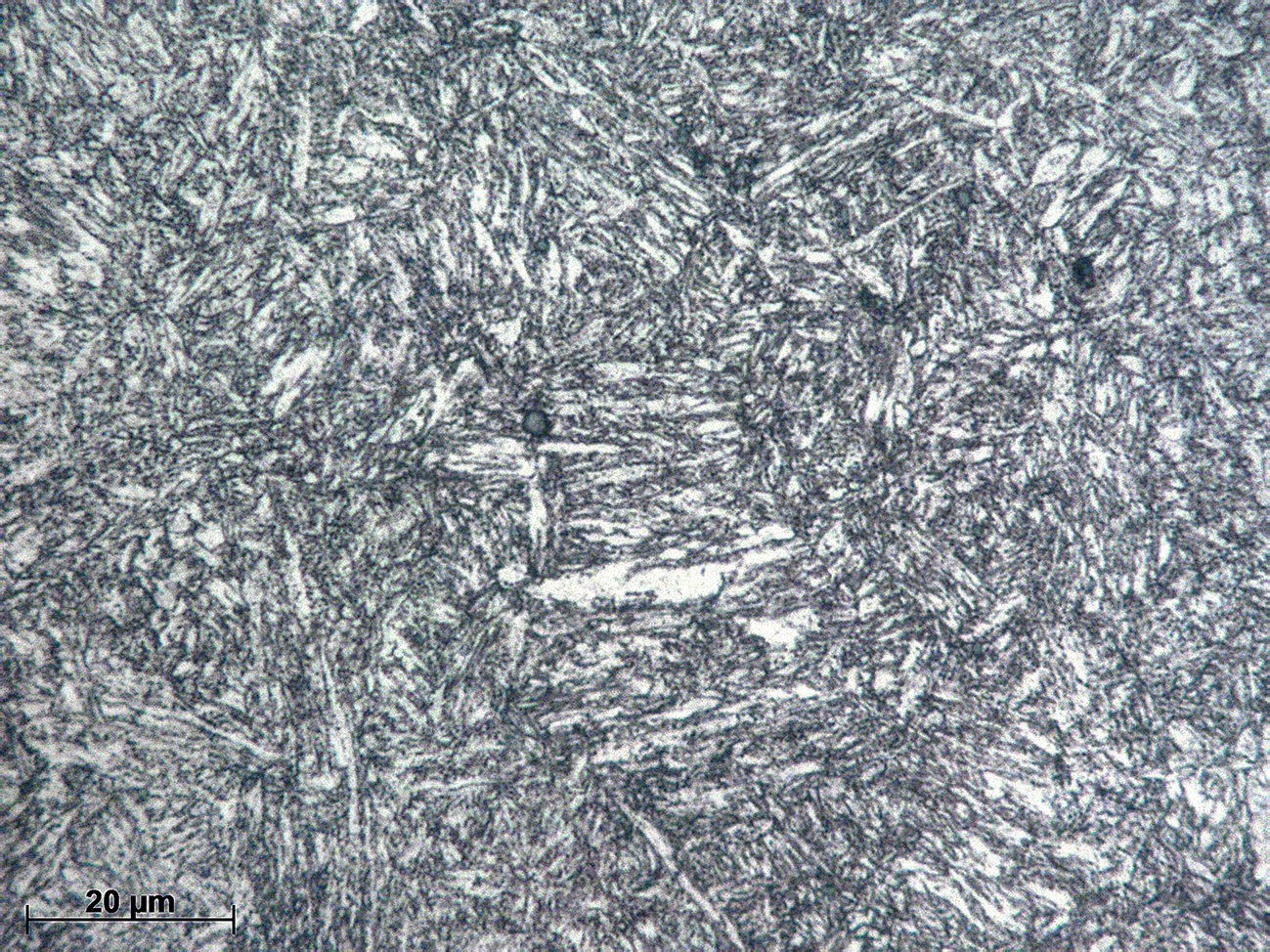

X26

Carbon steel (0,35%C) Quenched and Tempered 600ºC-2h

Composition: Carbon steel (0.35%C, hypoeutectoid).

Processing: Hot-rolled. Annealing (870ºC - 1h), Water quenching and Tempering (600ºC - 2h).

Etching: 10-15 s immersion in 2% nital.

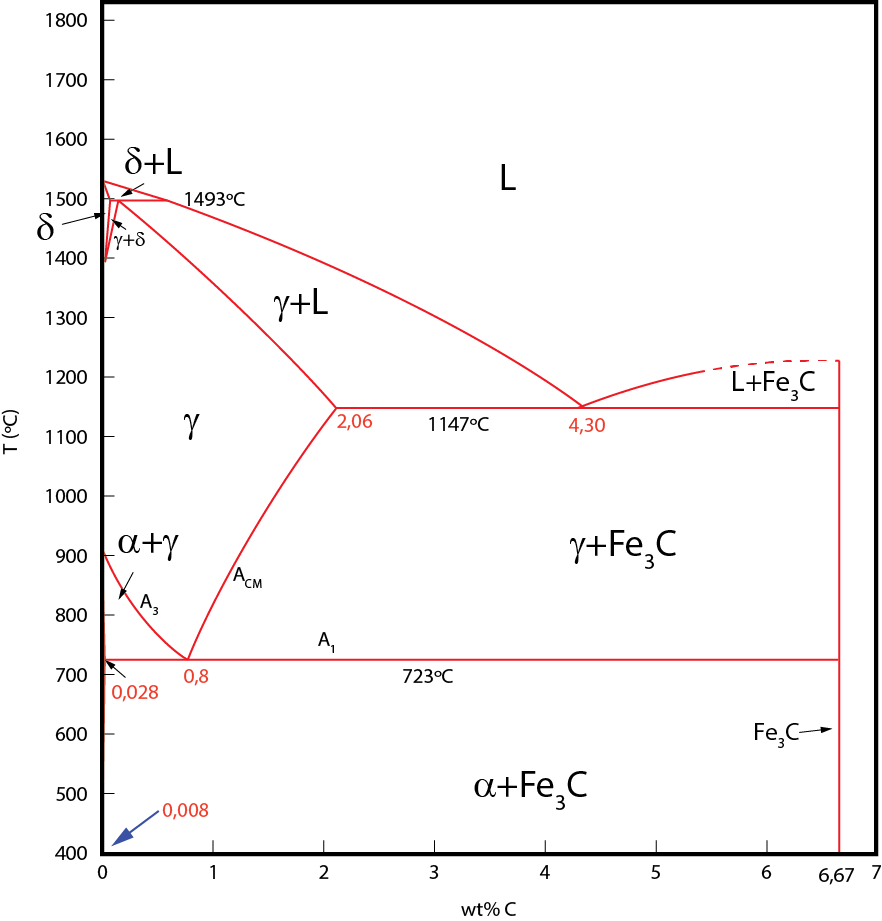

This is the same steel as the one in the X25 specimen, but this was water quenched and tempered. In steels, tempering is performed at temperatures below the eutectoid isotherm for varying times depending on the desired properties. The goal is to aid diffusion and transform the hard and brittle martensite into less brittle structures. At 600ºC, the steel is within the ferrite + cementite field (see phase diagram). Therefore, at this temperature, carbon atoms will diffuse out of the BCT structure of the martensite and form carbides, leaving behind a matrix of ferrite (BCC). Cementite precipitates are hardly distinguishable in these micrographs, but they appear as fine globular particles in between the ferrite needles.

Fe-Fe3C diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International