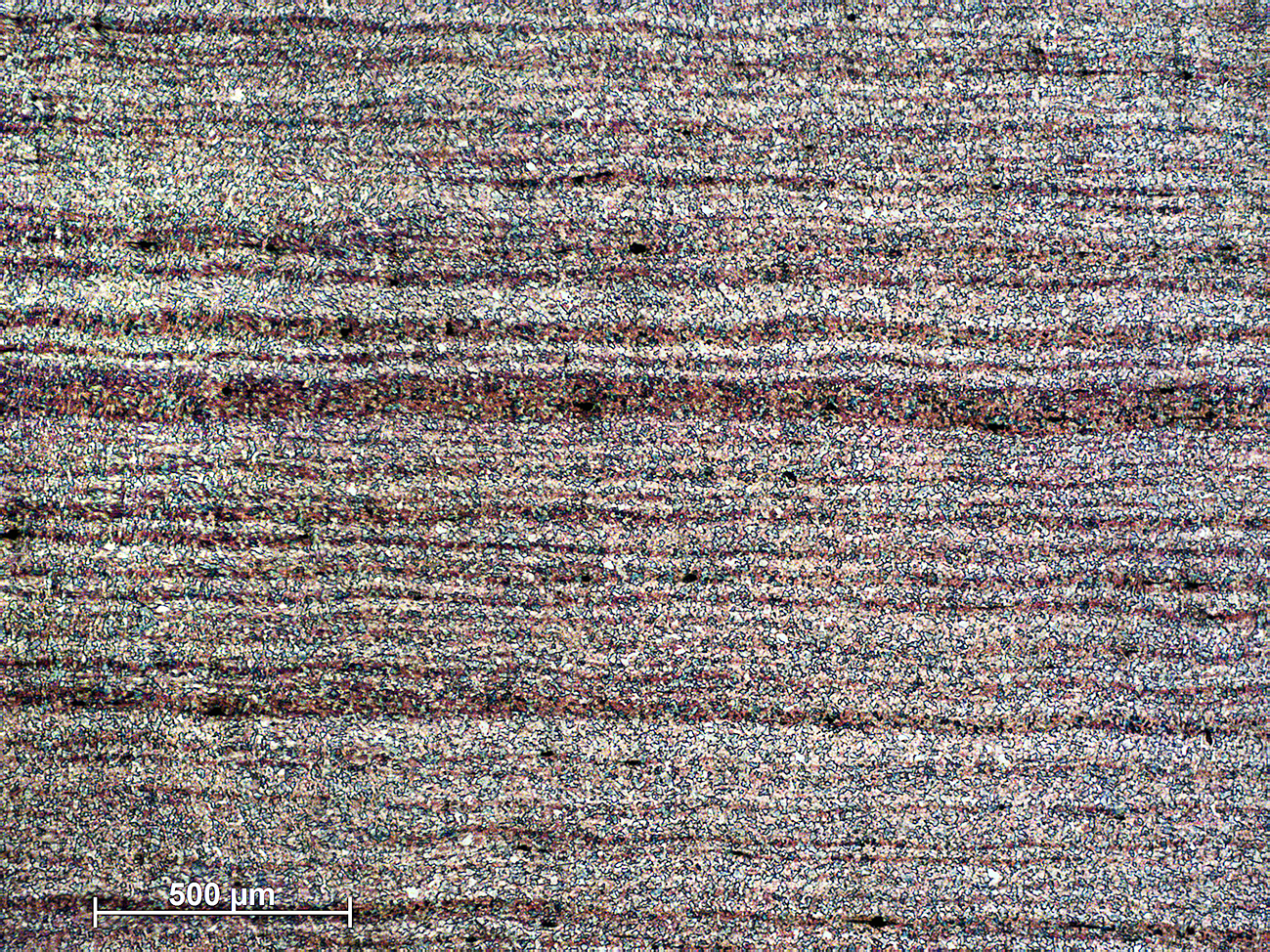

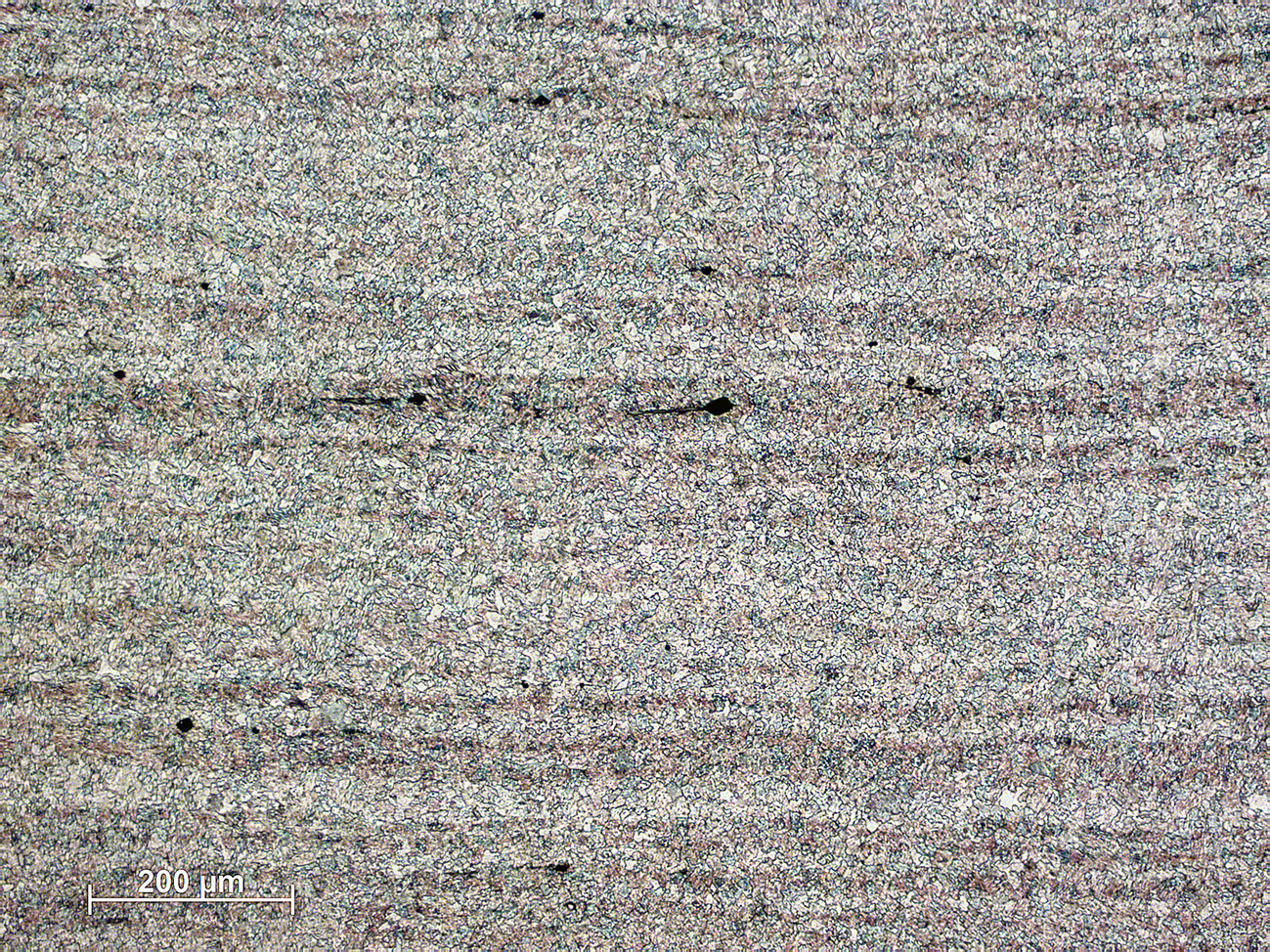

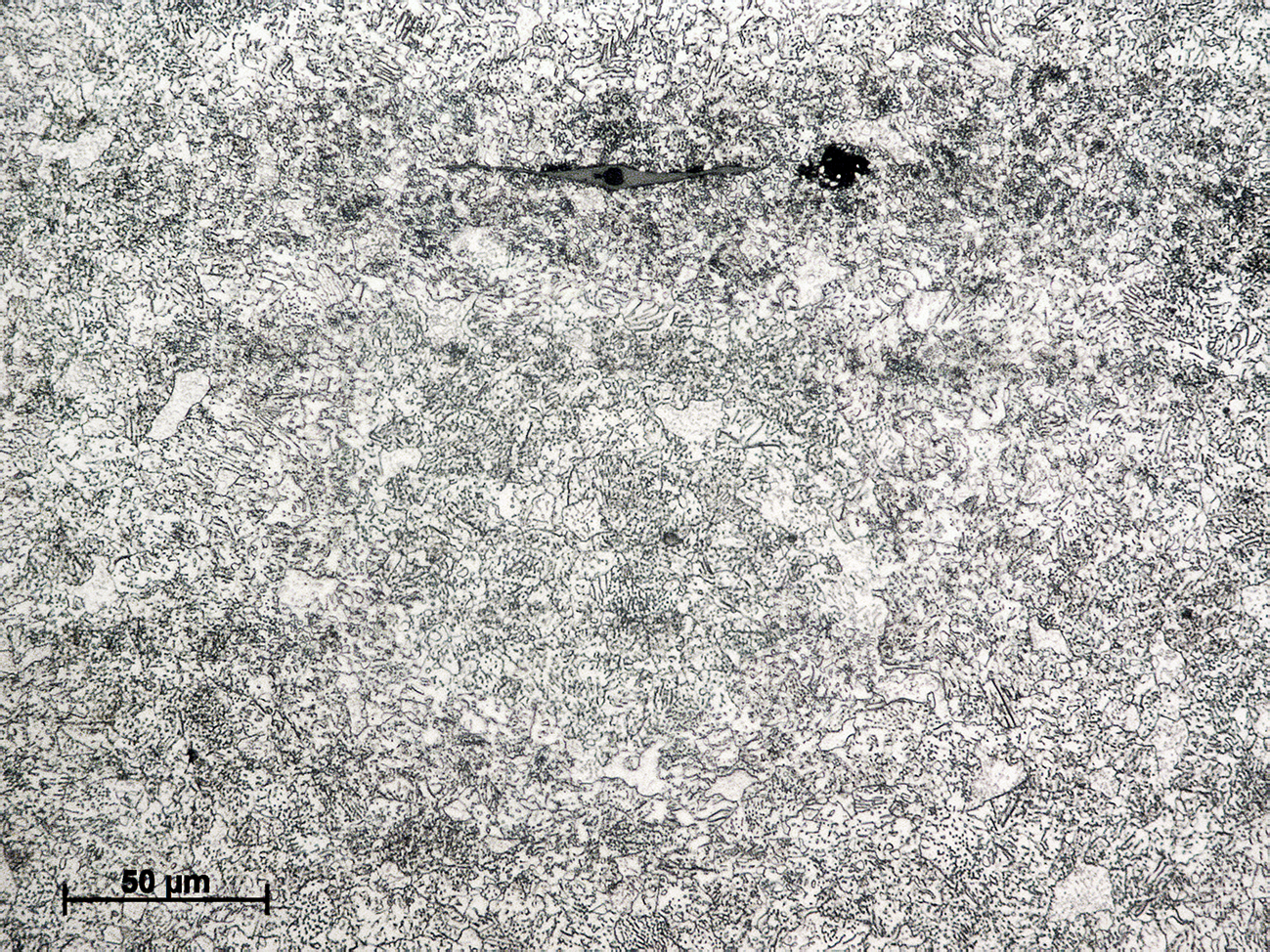

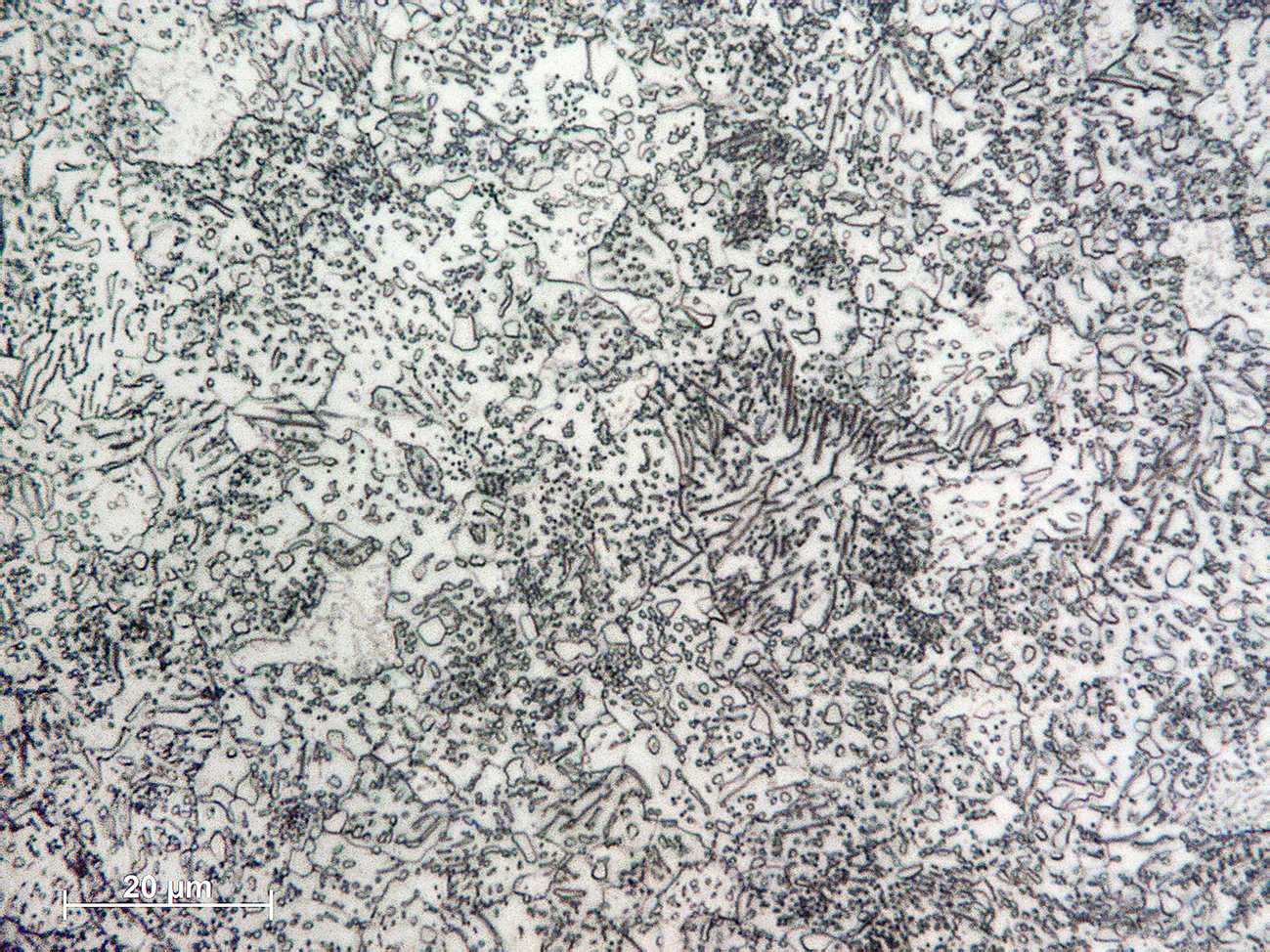

AC9

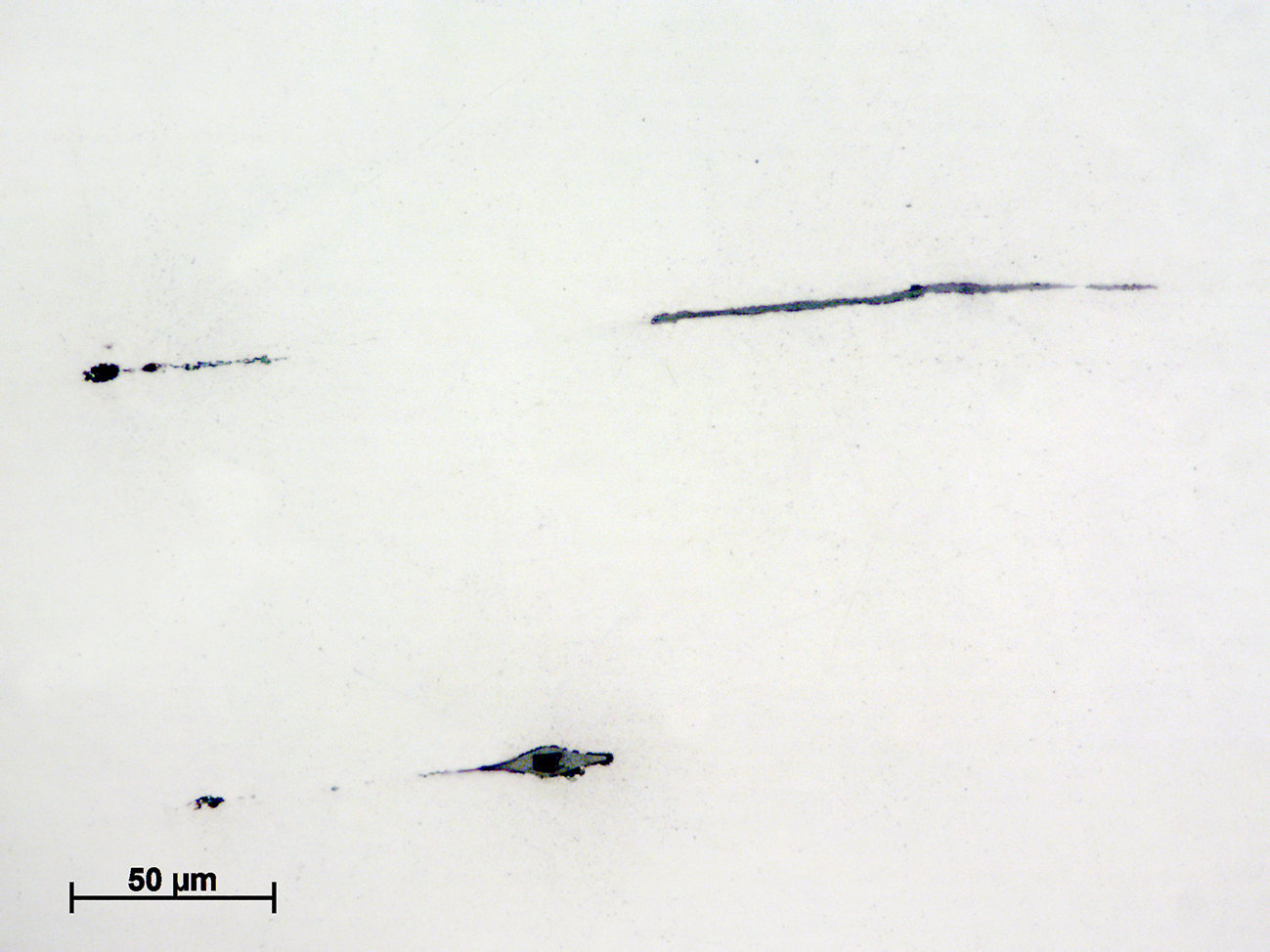

F522 (homogeneous carbides)

Composition: Tool steel (0.9-1.0 C; 1.0-1.2 Mn; <0.30 Si; <0.3 P; <0.3 S; 0.40-0.60 Cr; 0.5 W; 0.12 V)

Processing: Forging 1050 ºC, Cooling down to 850 ºC, furnace cooling (10-20 ºC/h) until 600ºC and final cooling until room temperature.

Etching: 20-40s immersion in 2% nital.

This is a low alloy tool steel for cold working operations. It has an excellent wear resistance and is able to hold a good cutting edge. This is a material that is often used when the expense of a high chromium tool steel would not be justified. Common applications include highly stressed plastic moulds, cold forming dies, cutting and punching tools of all types, shear blades, reamers, guide pins, taps, measuring tools, deep drawing tools, etc. The microstructure shows directionality due to the forging operations carried out at 1050ºC. The slow cooling through the eutectoid temperature favoured the precipitation of globular carbides (mostly Fe3C). The final microstructure consists of a ferritic matrix, dispersed globular carbides and some regions of non-spheroidized pearlite. With the applied treatment the hardness is around 250-270 HV (25-28 HRC). This steel can achieve 63-65 HRC by quenching from 780-820 ºC and tempering at 200-250ºC in a salt bath.

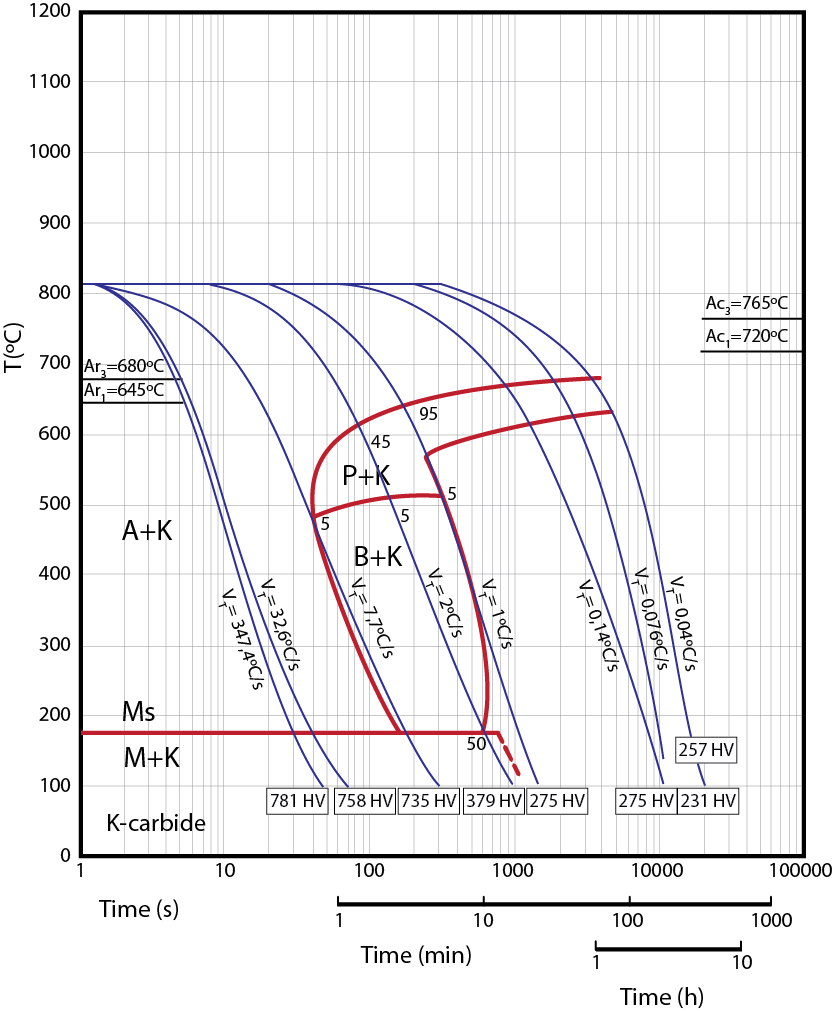

F522 CCT diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.