2024

Al-Cu-Mg wrought alloy

Composition: Al-4.54Cu-1.51Mg-0.63Mn-0.17Fe-0.08Zn-0.06Si-0.03Ti-0.01Cr.

Processing: T3 temper.

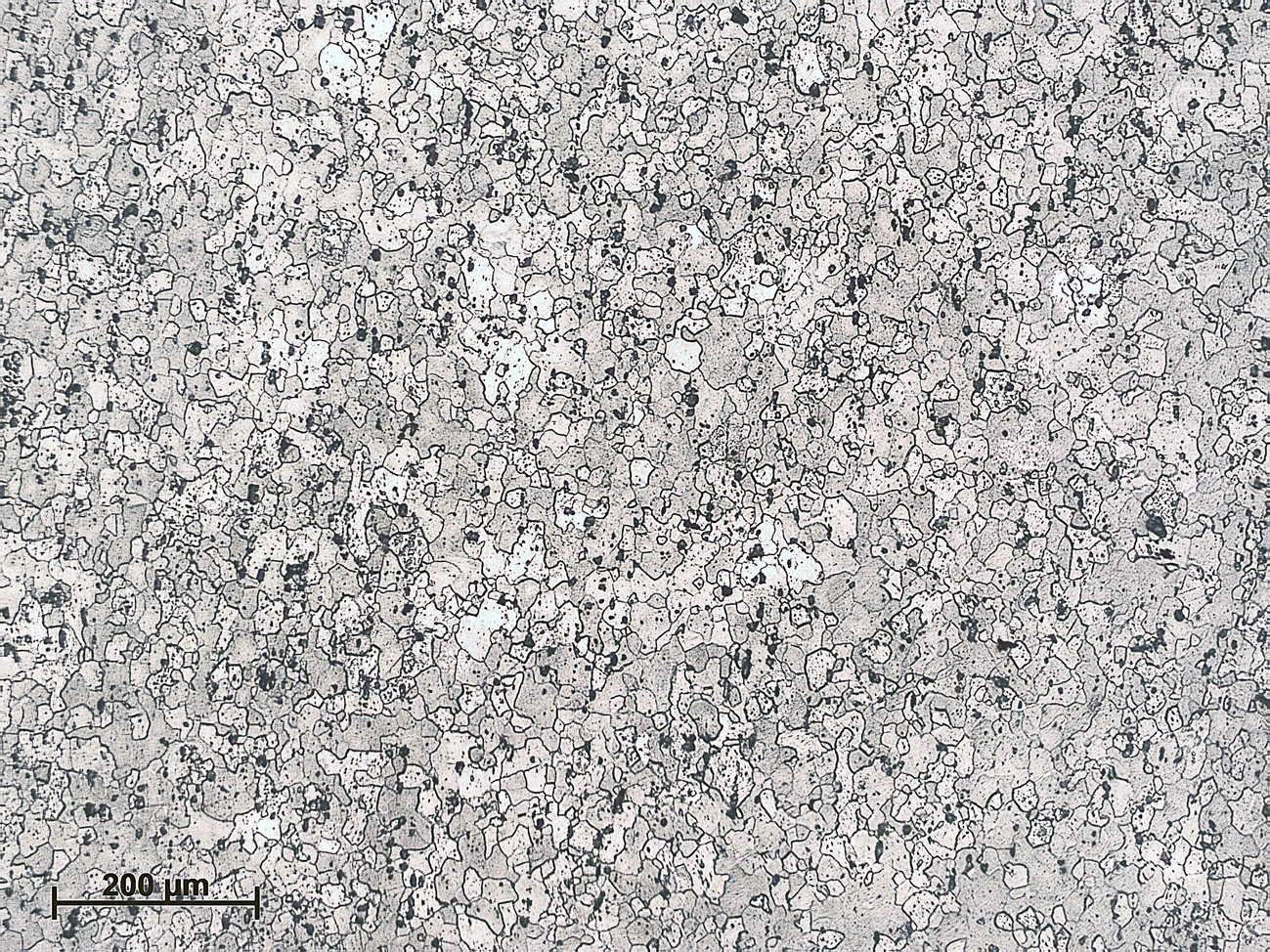

Etching: 30-120 s immersion in mixture of acids (HCl+HF+HNO3).

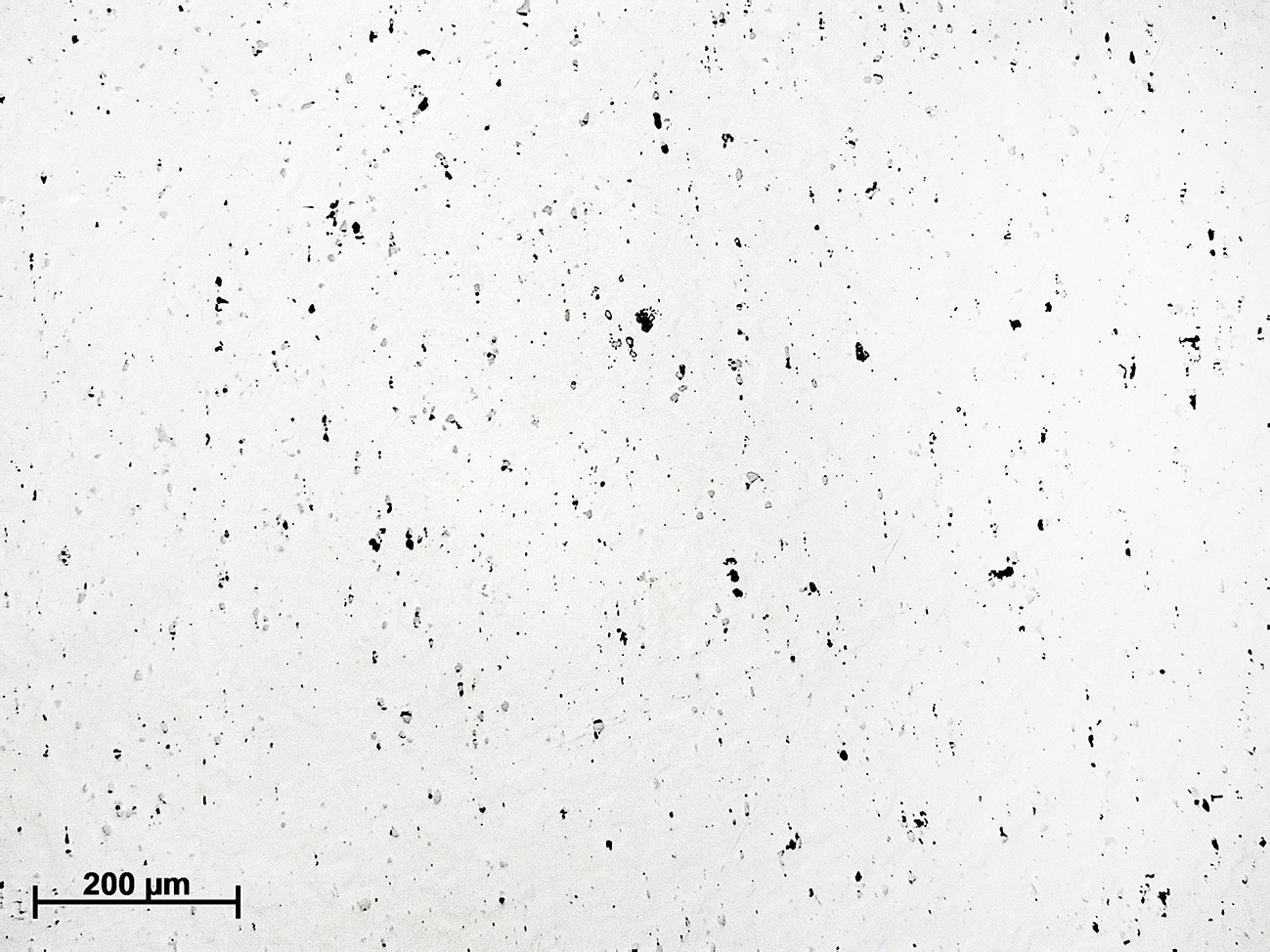

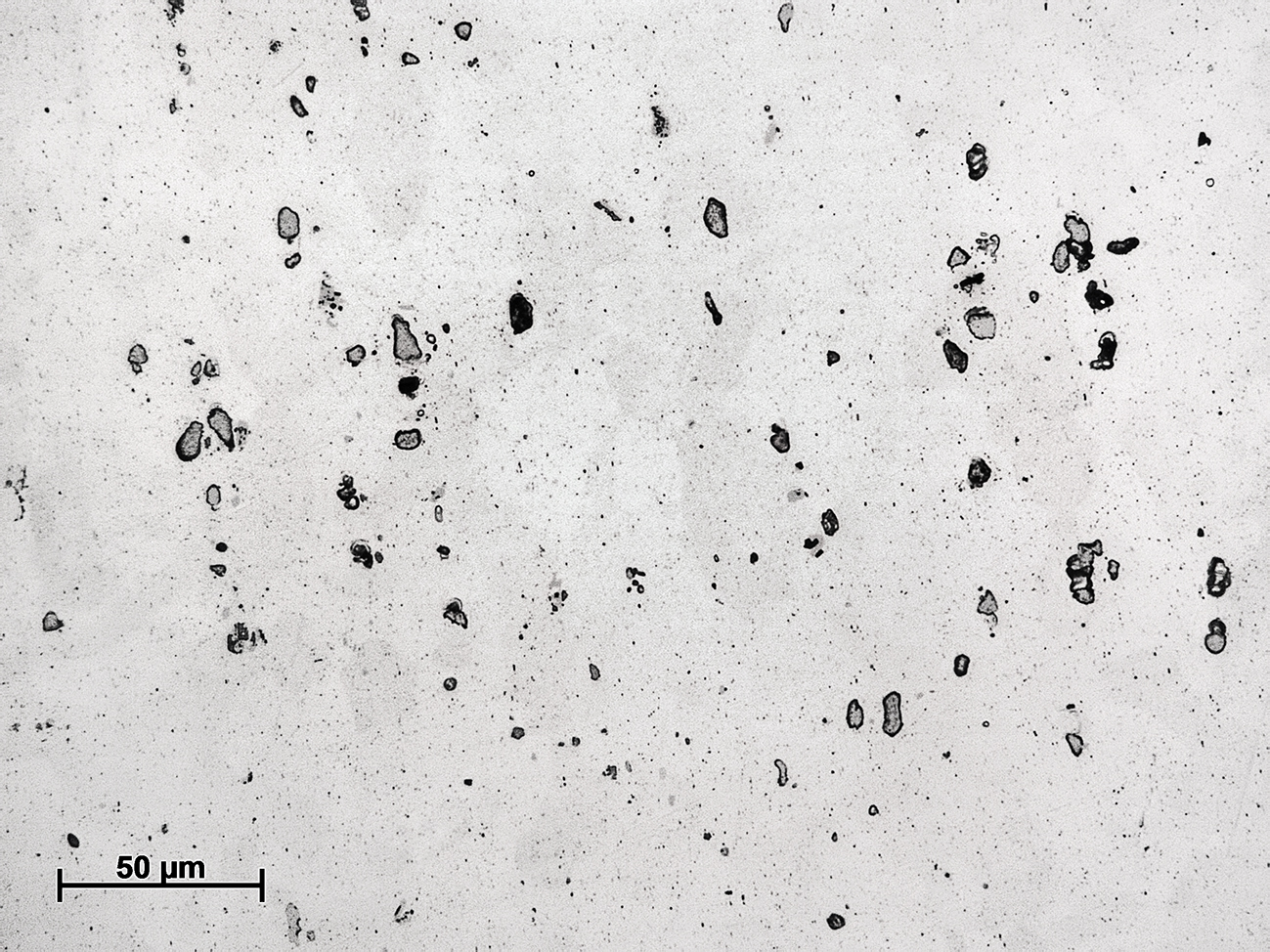

The 2024-T3 alloy that is presented in the micrographs shows equiaxed grains of α-Al phase and several intermetallics that are better differentiated in the polished (non-etched) specimen:

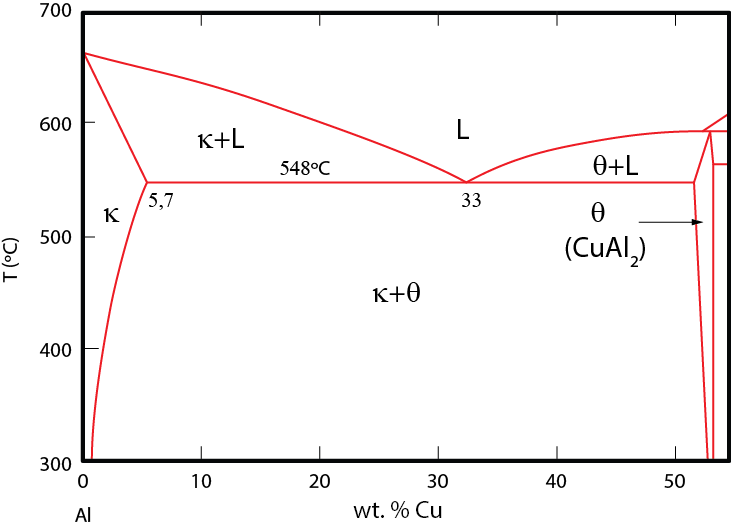

-S phase (Al2CuMg, dark) and θ phase (Al2Cu, gray-pink): round shape and smaller than 10 µm.

-α phase (Al-Cu-Fe-Mn-(Si)): poligonal/irregular, <20 µm, brown.

-Dispersoids (Al-Cu-Mn): round, 100-500 nm and hardly visible by optical microscopy.

-S phase (Al2CuMg): submicrometric. This small precipitates forms during aging and is distributed in the entire specimen. However, its small size (10- 600 nm in diameter) makes it invisible by optical microscopy.

This is one of the most common alloys for structural components in the aeronautic sector due to its low density and high specific strength. However, the presence of copper makes the alloy more susceptible to corrosion attack.

Al-Cu diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.