Ti6Al4V-F

Fine Widmanstätten

Composition: Ti-6%Al-4%V.

Processing: Annealing (1050ºC - 10 min), Air cooling.

Etching: 30-120s immersion in mixture of acids (HCl+HF+HNO3).

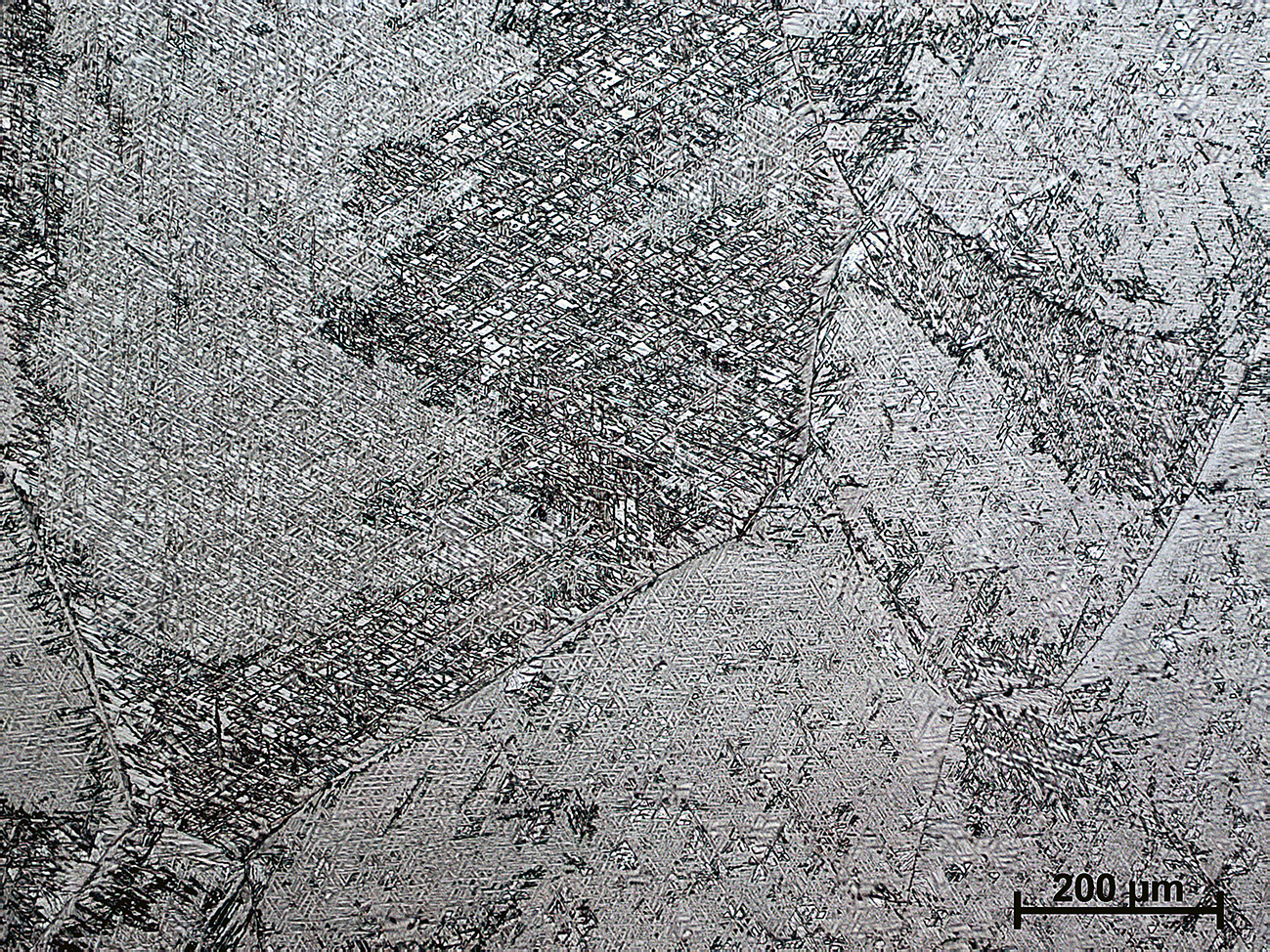

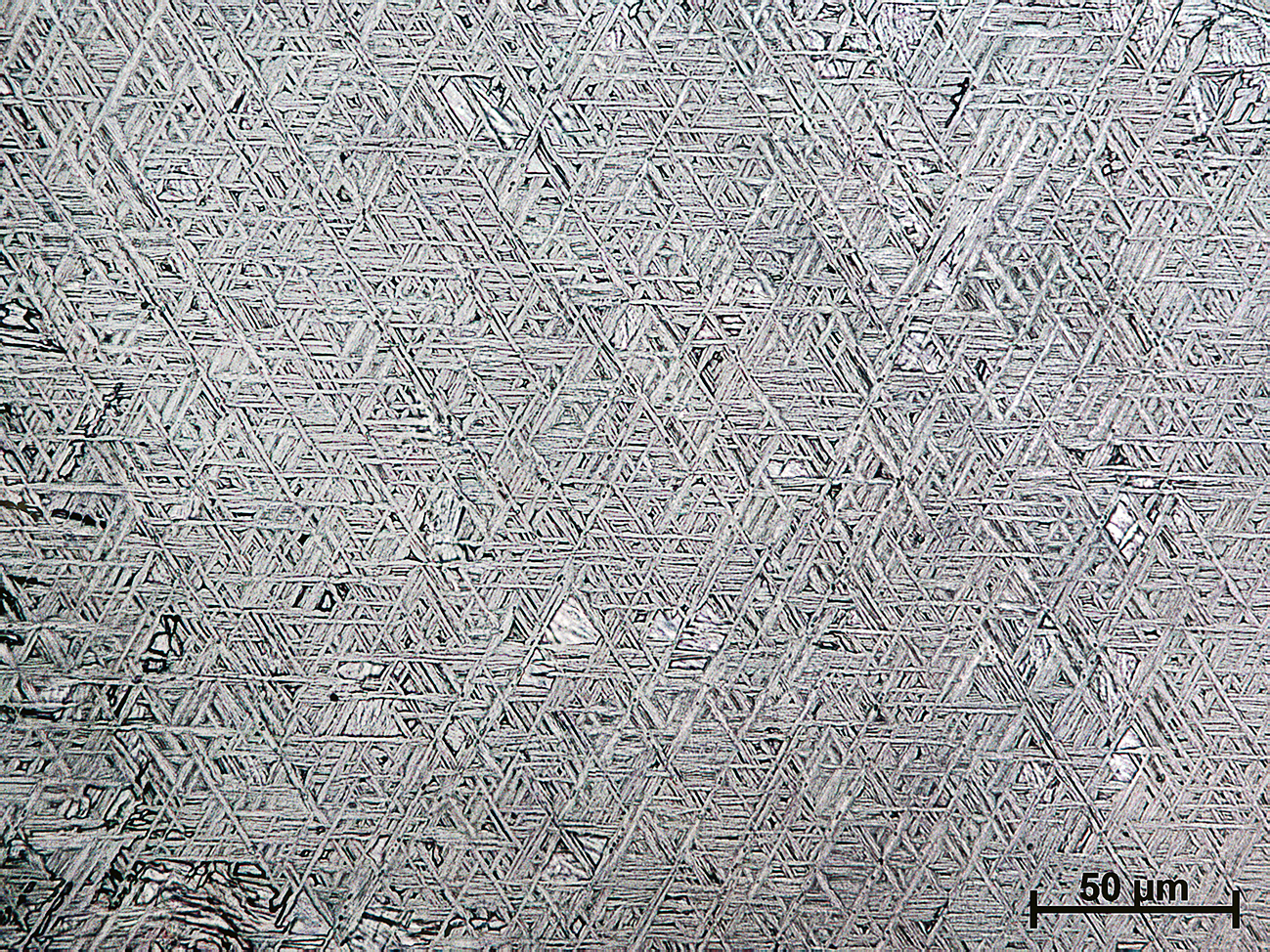

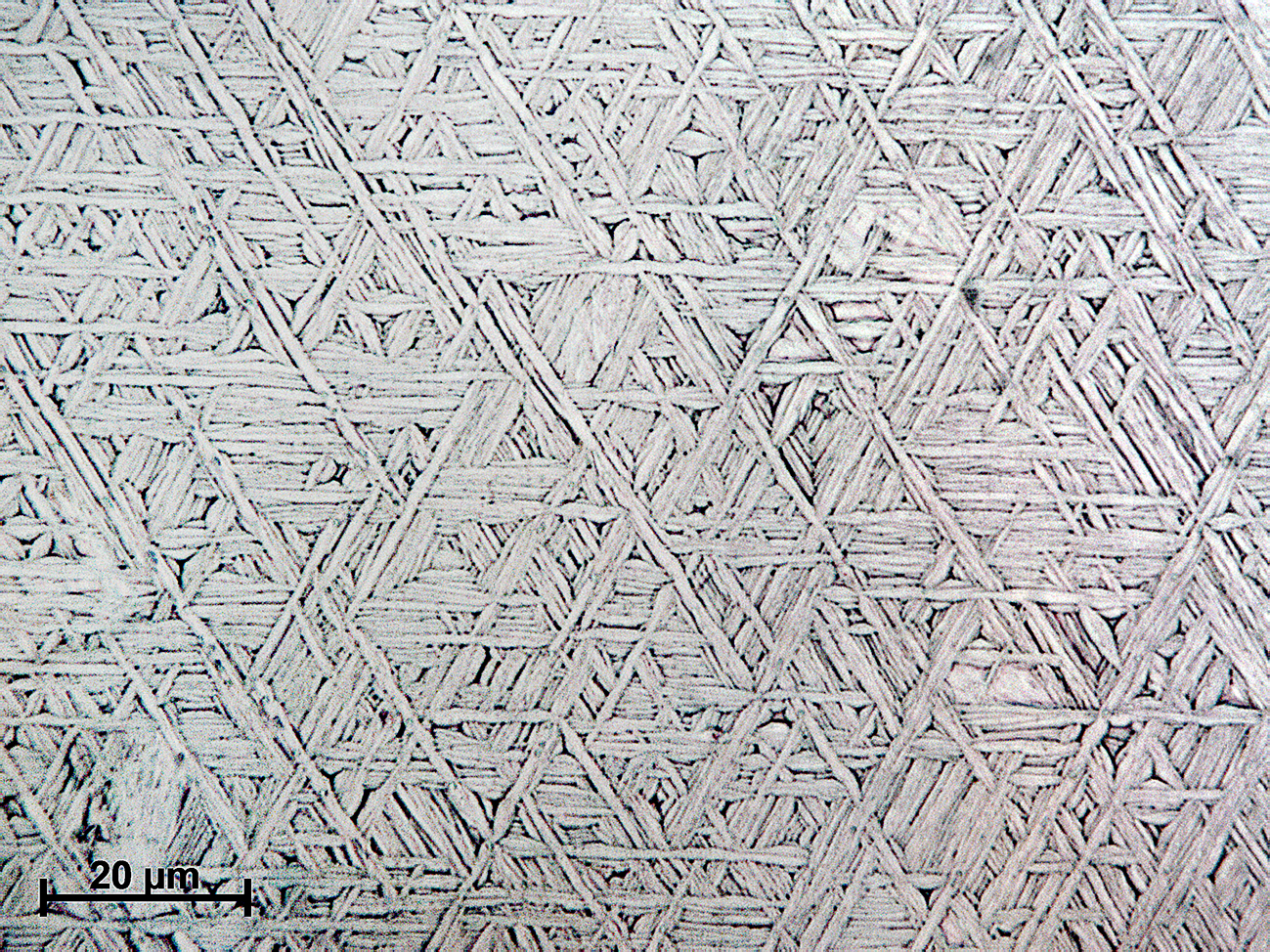

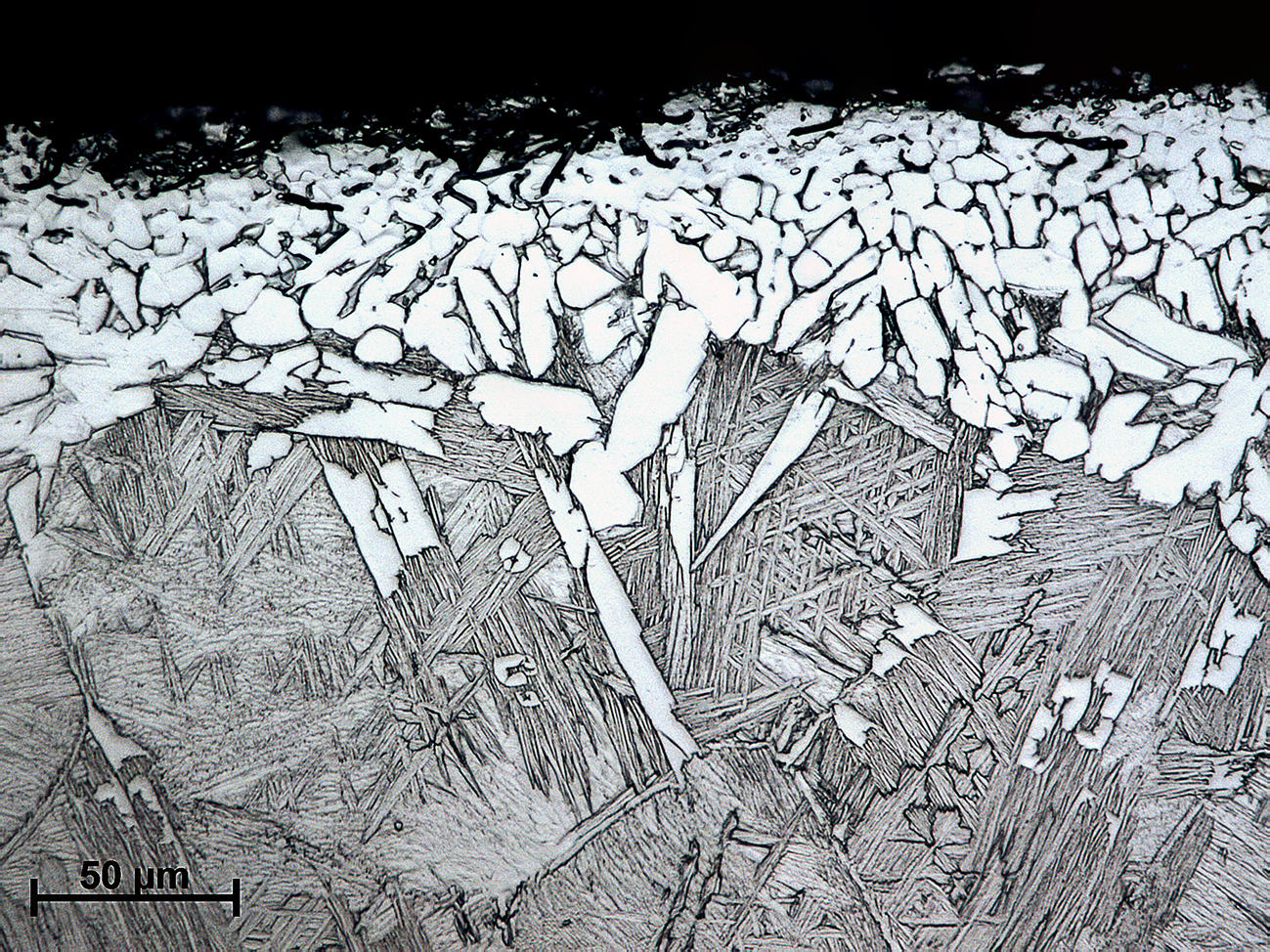

The micrographs show a Widmanstätten-type microstructure with a characteristic pattern. This is also known as basket weave microstructure, where intersecting lamellae of α are decorated with retained β in between them. In three dimensions, the α phase has in a reality a disk-shape morphology. At low magnifications is possible to distinguish the original β grains thanks to the coarse grain boundary α layer that is formed during the initial stages of cooling.

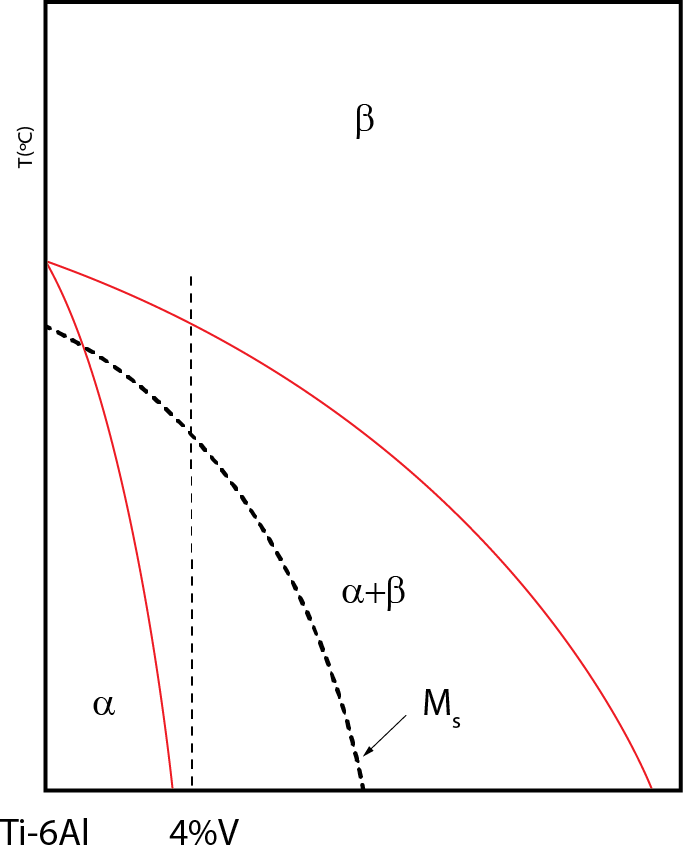

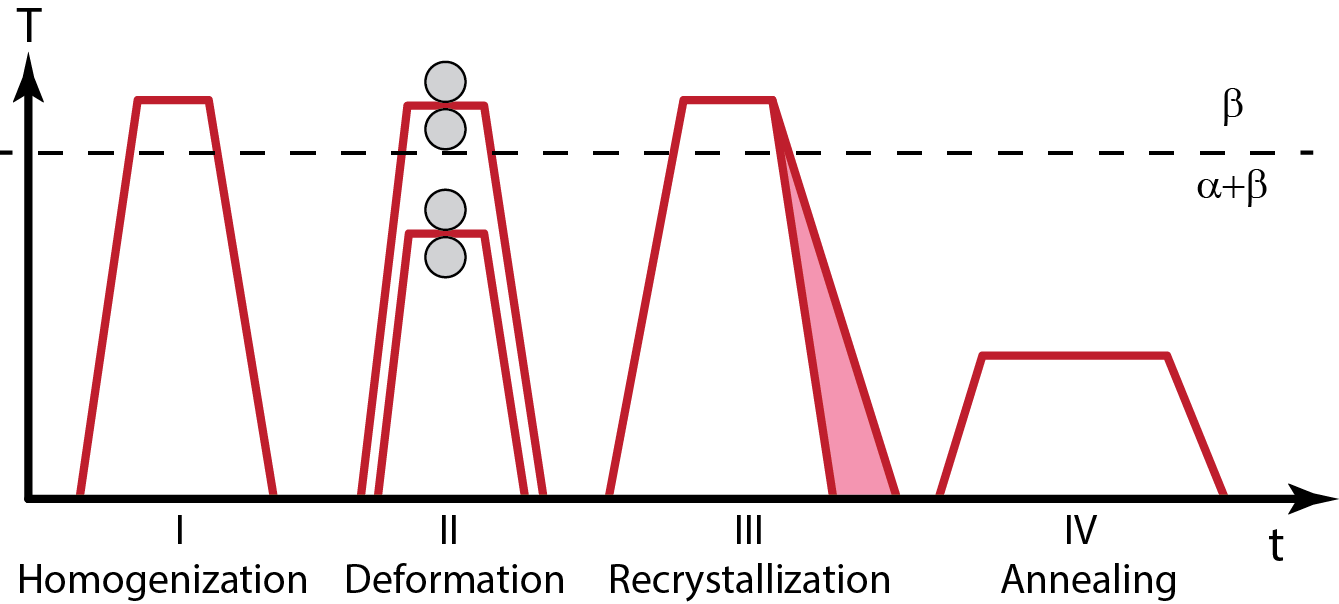

This lamellar microstructure is usually obtained in specimens previously homogenized and rolled (Stages I and II in the diagram) that are heat treated 30-50ºC above βtransus (999ºC, Stage III) and cooled in water or with a stream of air, depending on the thickness of the specimen. During stage III, it is important to avoid high temperatures in order to limit the coarsening of the β grains. The final Stage IV is standard procedure in order to release residual stresses.

The morphology, size and quantity of α lamellae mostly depends on the cooling rate during Stage III. In this example, fast cooling results in thin lamellae and small colonies in the interior of each grain. In each colony, α lamellae are in a parallel arrangement. The layout of the surrounding colonies tries to minimize the elastic strains induced during the transformation. One characteristic of this Widmanstätten structure is that in each β phase grain there are only six types of non-parallel planes where α lamellae grow.

When heat treatments are carried out in the presence of oxygen (α-stabilizer) it is common to develop a surface layer with equiaxied α grains. This layer is detrimental from a mechanical point of view.

Ti6Al-V diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.