X13

Brass (42%Zn)

Composition: Cu-42%Zn.

Processing: Sand casting, Annealing (800ºC-1h) and slow cooling until room temperature.

Etching: 30 s immersion in FeCl3 alcoholic solution.

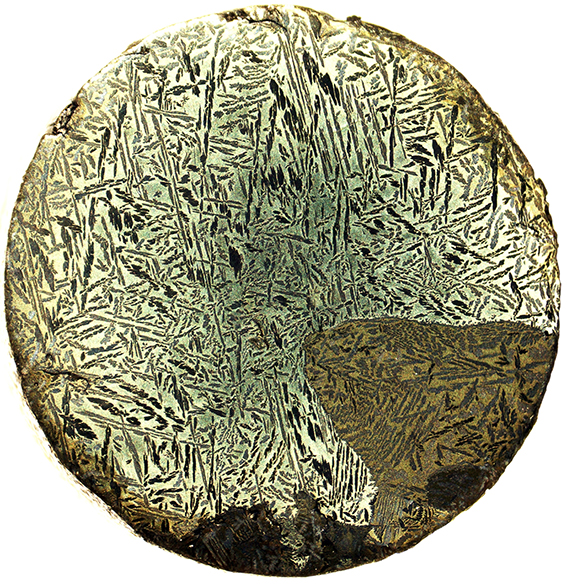

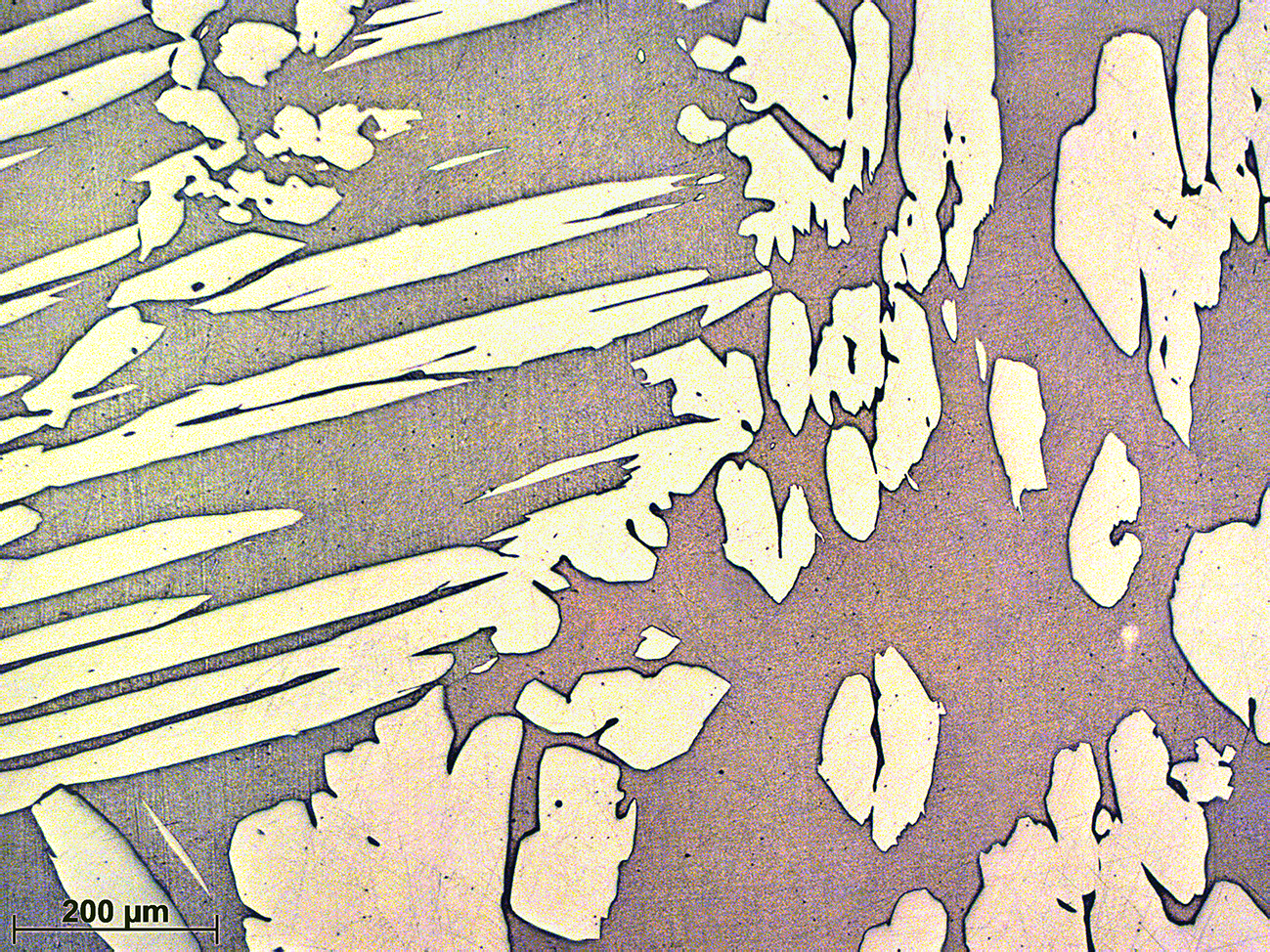

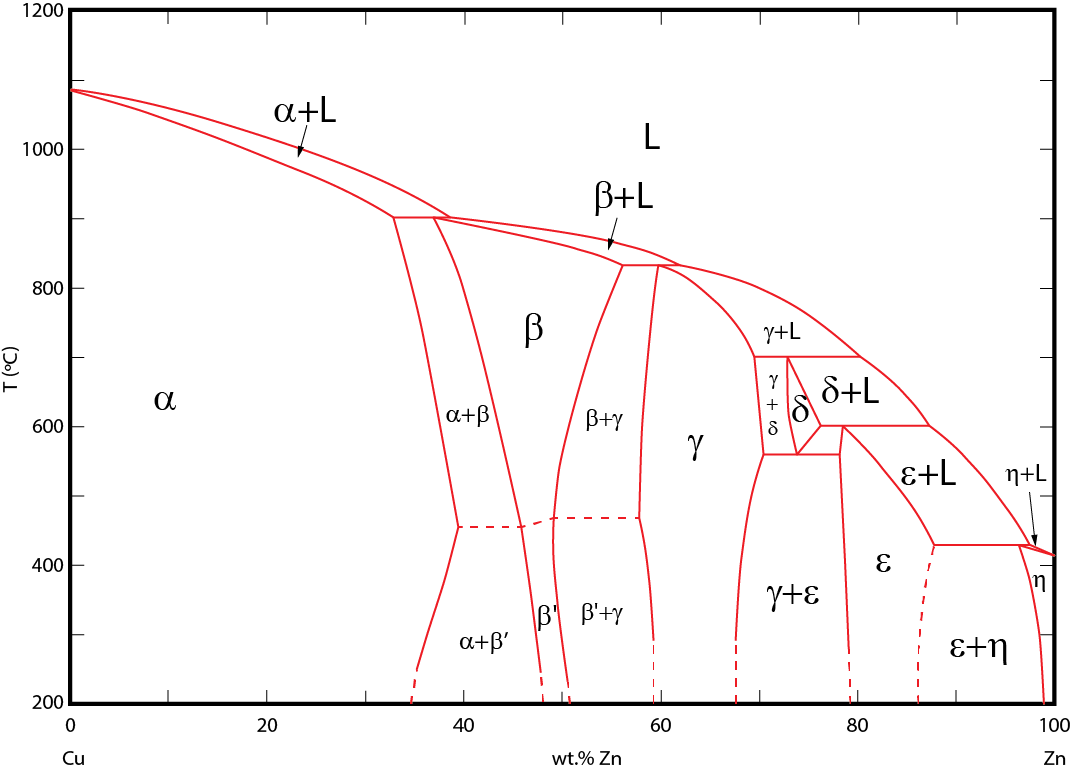

Slow cooling from 800ºC (β region) until room temperature allows for complete precipitation of the α phase as predicted by the phase diagram. The macrostructure shows a matrix of large equiaxial β grains, which coarsened during annealing, and α phase needles that are visible to the naked eye. The amount of these needles is greater than that observed in X10 as cast specimen. Therefore, this sequence of specimens demonstrates that the cooling conditions from the β region influence the size and degree of precipitation of the α phase.

Cu-Zn diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International