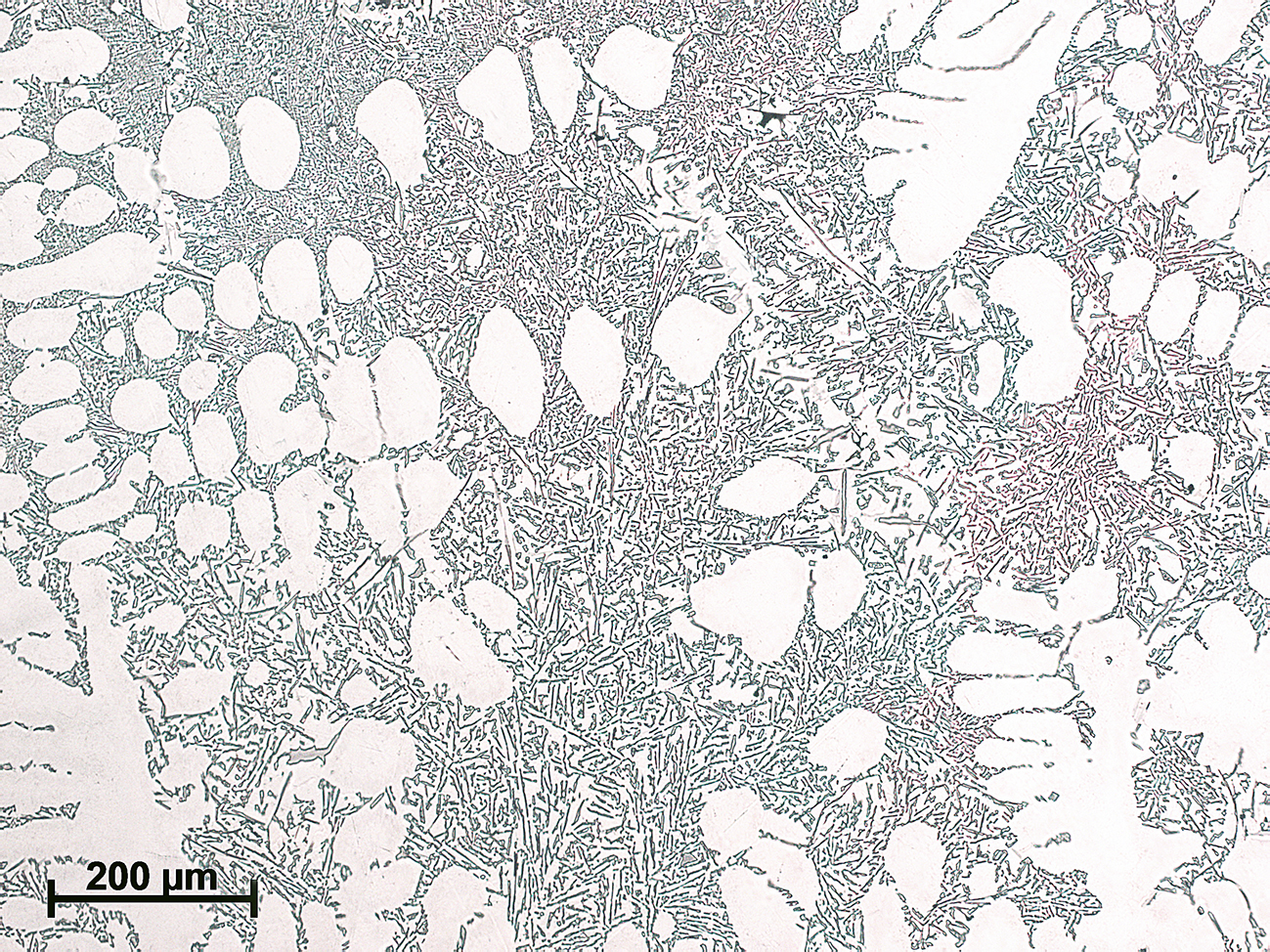

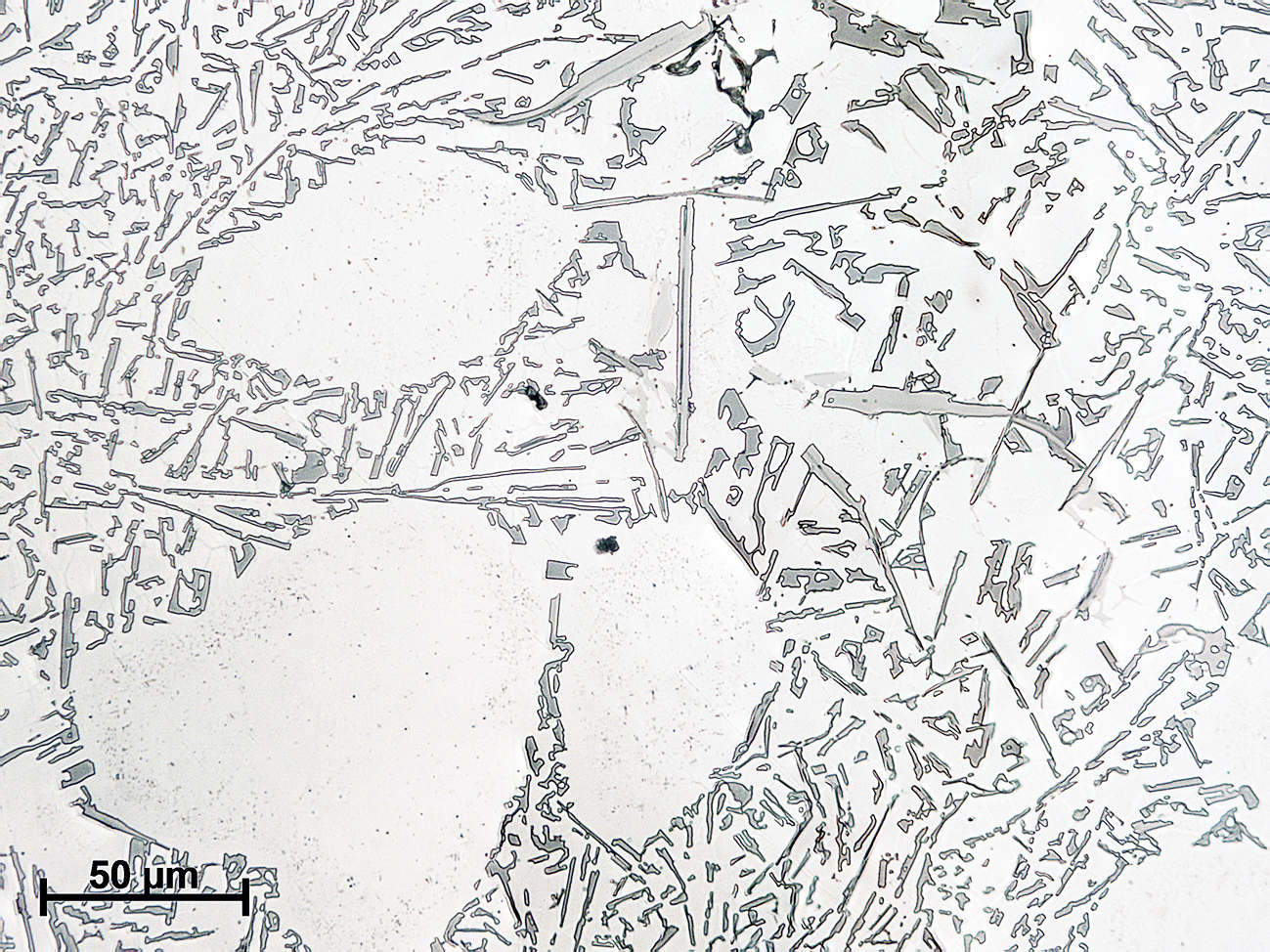

A361

Al-Si alloy, Pressure die casting

Composition: Al-10.5%Si-0.53%Fe-0.35%Mg-0.12%Mn-0.10%Cu.

Processing: Pressure die casting.

Etching: 10-45s immersion in 0.5% HF aqueous solution.

This specimen shows the characteristic structure of Al-Si cast alloys with dendrites of primary α-Al phase and the eutectic α-Al+Si located at the interdendritic spaces. At higher magnification the acicular morphology of Si is revealed as well as the presence of an intermetallic compound with a plate-like morphology. This compound is known as β-AlFeSi and it forms due to the presence of Fe impurity. This is an undesireable second phase from mechanical and corrosion points of view; it decreases toughness due to its effect as a stress raiser and it serves as a cathode in corrosion processes.

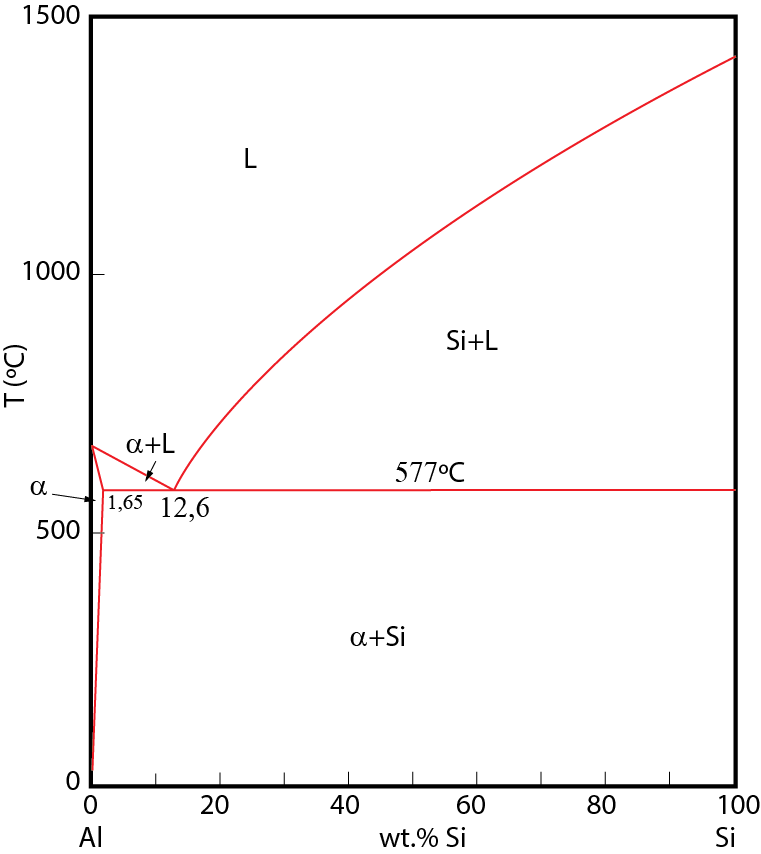

Al-Si diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.