X23

Cu-Al alloy (11.3%Al)

Composition: Cu-11.3%Al.

Processing: Sand casting. Annealing at 900ºC, Furnace cooling.

Etching: 5-10 s immersion in FeCl3 alcoholic solution.

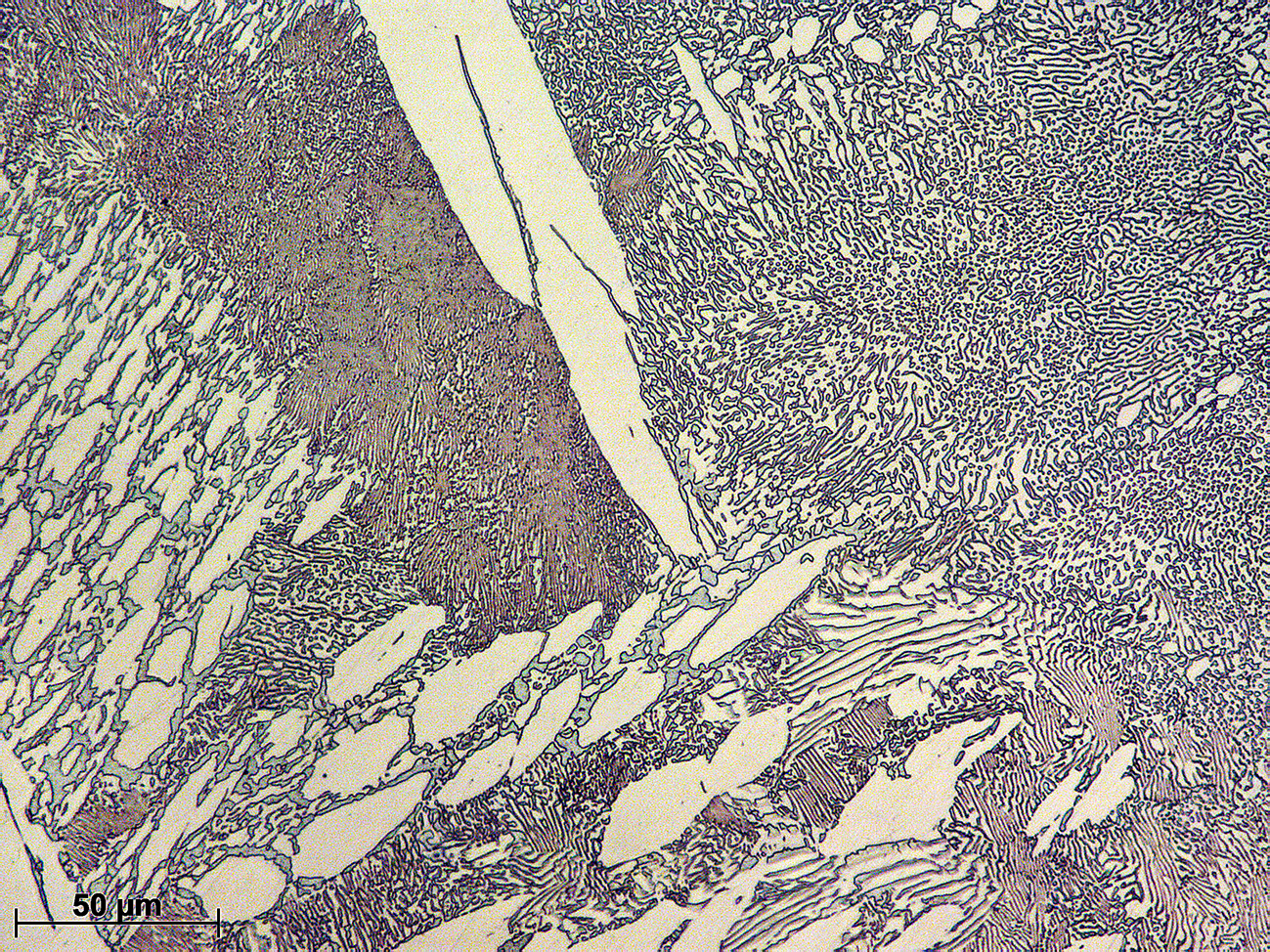

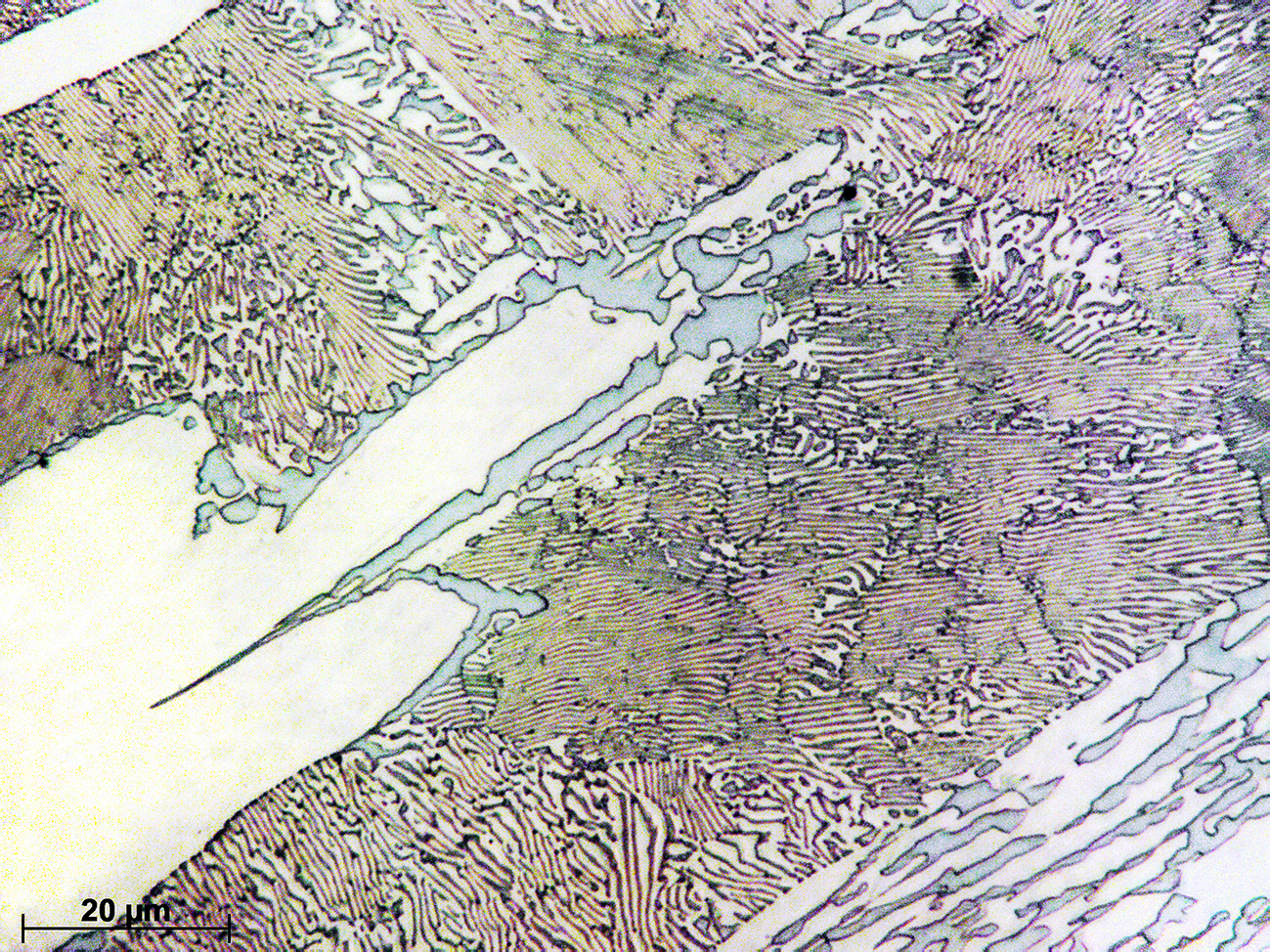

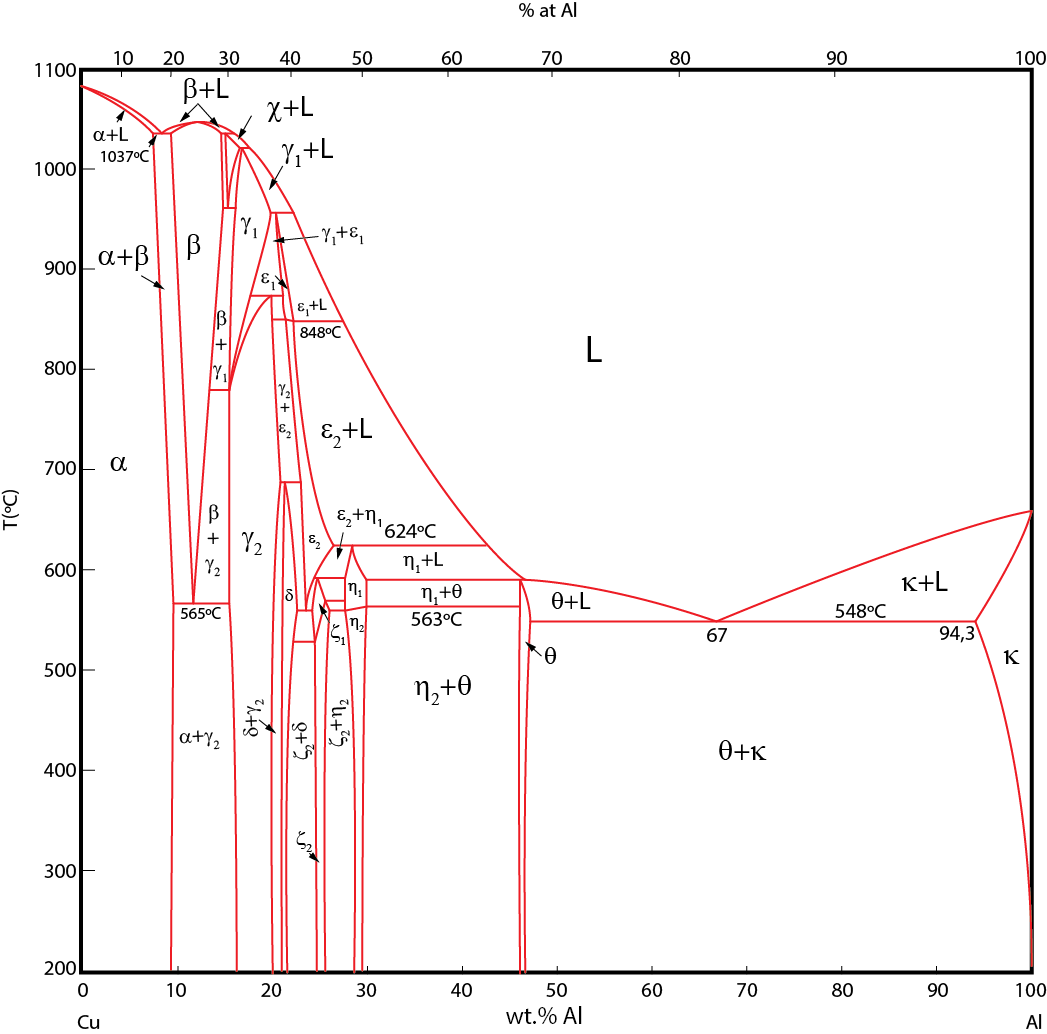

This alloy is hypoeutectoid as it has a slightly lower concentration of Al in comparison to X22. The macrograph reveals equiaxial grains with a substructure. At 900ºC, the alloy is in the monophasic β region. Then, during slow cooling, proeutectoid α precipitates within the β grains with a Widmanstätten-type microstructure. At 565ºC, when the β phase reaches the eutectoid temperature (11,8% Cu), there is the eutectoid transformation with simultaneous precipitation of α and γ2 in a lamellar arrangement. Therefore, this sequence is very similar to that observed in hypoeutectoid steels. The eutectoid aggregate shows the caracteristic morphology of pearlitic colonies with variable spacing between the lamellae depending on their orientation with respect to the sectioning plane.

Cu-Al diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International