8090

Al-Li alloy

Composition: Al-1.12%Li-0.82%Cu-0.06%Mg-0.04%Zr-0.02%Fe-0.024%Si.

Processing: Forging and precipitation hardening.

Etching: 30s-120s immersion in mixture of acids (HCl+HF+HNO3).

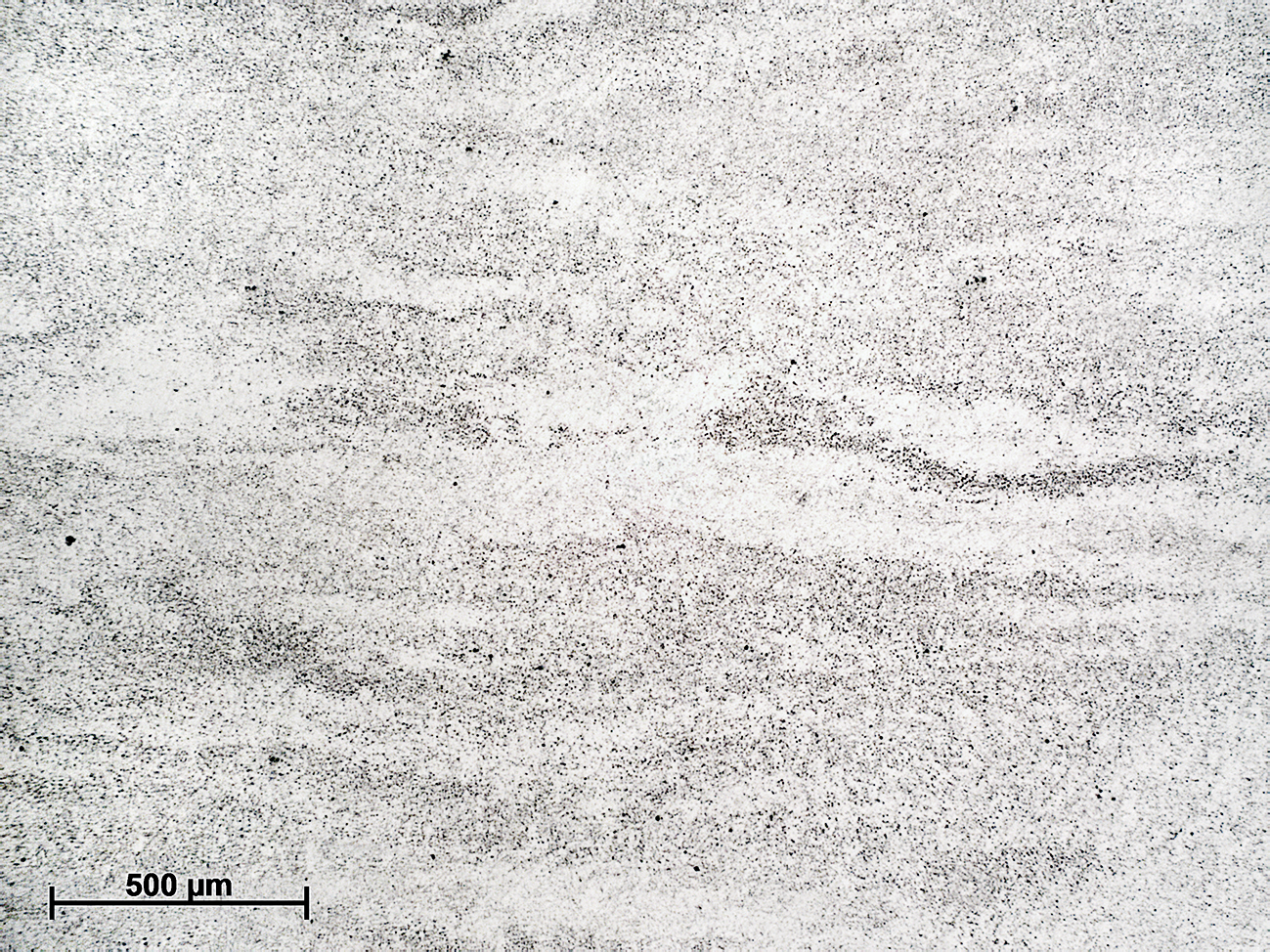

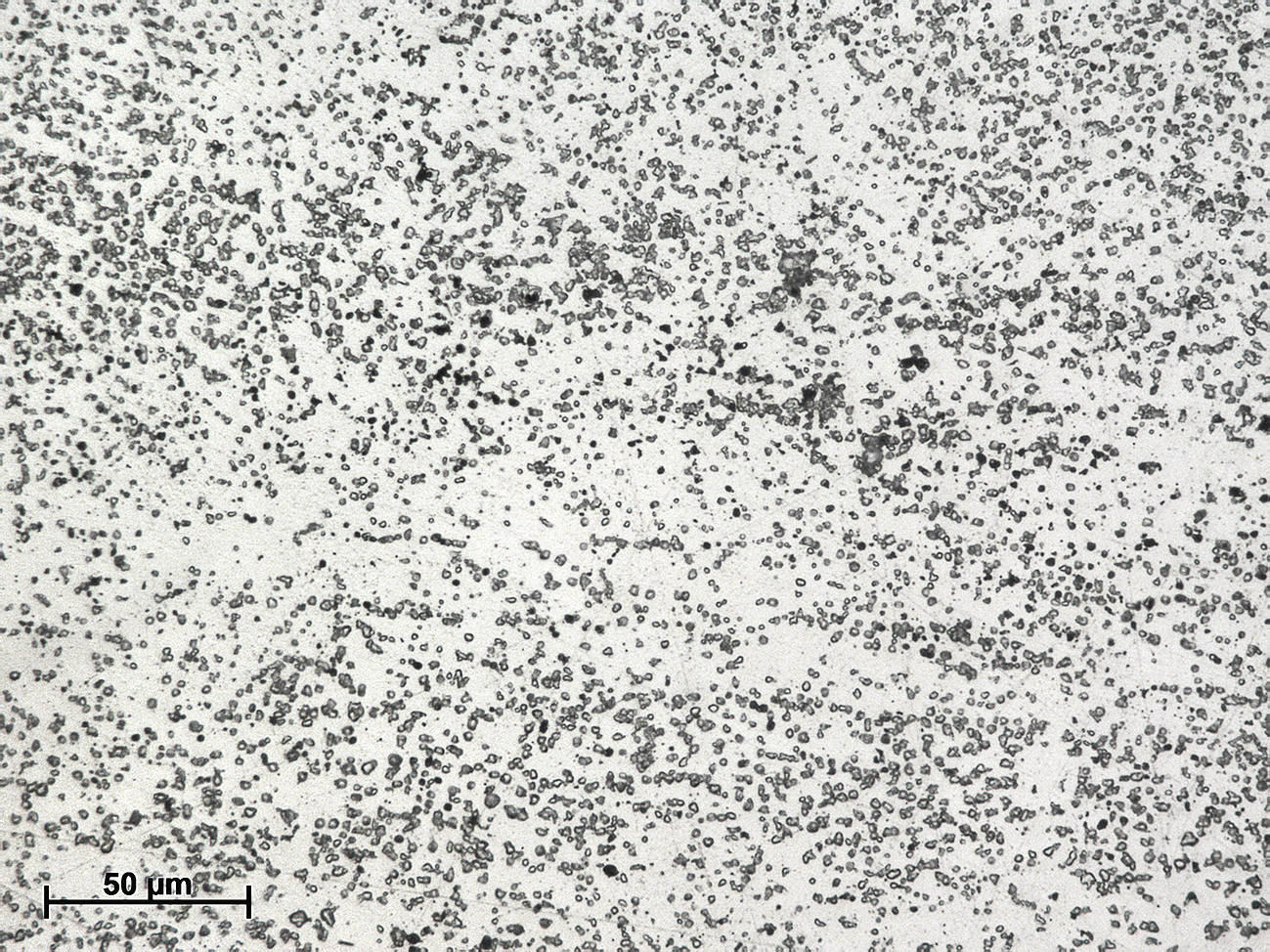

The 8090 alloy consists of small equiaxed α-Al grains (1 µm) and intermetallics (1-2 µm) tha are aligned in the extrusion direction. The grains are not visible in the micrographs, but the arrangement of intermetallics is visible. The are two types of intermetallics, (i) spheroidal Al-Mg-Cu(Si) particles which possibly correspond to the S’-Al2CuMg phase (gray), and (ii) Fe-rich impurities, Al-Cu-Fe(Mg), which are poligonal, darker and larger. In this type of alloy is also common to see the β’-Al3Zr phase. However, this can only be seen by transmission electron microscopy. Something similar occurs with the metaestable δ´-Al3Li phase, which forms during precipitation hardening.

This alloy contains Li, which reduces the density by 10% and increases the yield strength by 11% in comparison to other aluminium alloys such as the 2024. The 8090 alloy shows superplasticity due ot its small grain size. This becomes very useful for advanced componentes in the aeronautic sector as well as in military and aerospace.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.