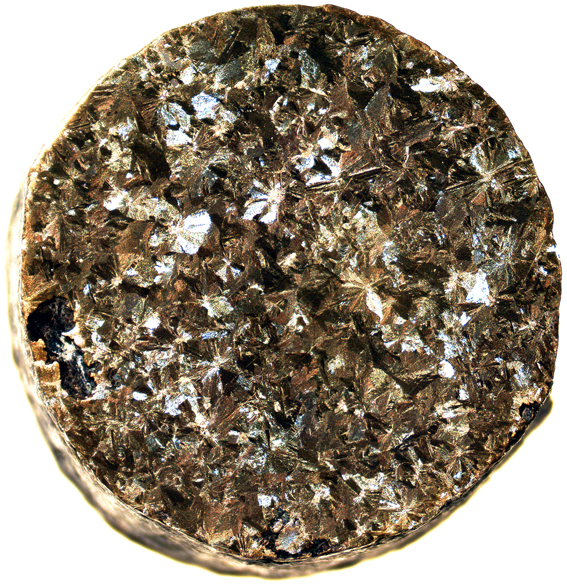

X21

Cu-Al alloy (11.8%Al)

Composition: Cu-11.8%Al.

Processing: Permanent mold casting. Annealing (900ºC- 1h) and slow cooling.

Etching: 5-10 s immersion in FeCl3 alcoholic solution.

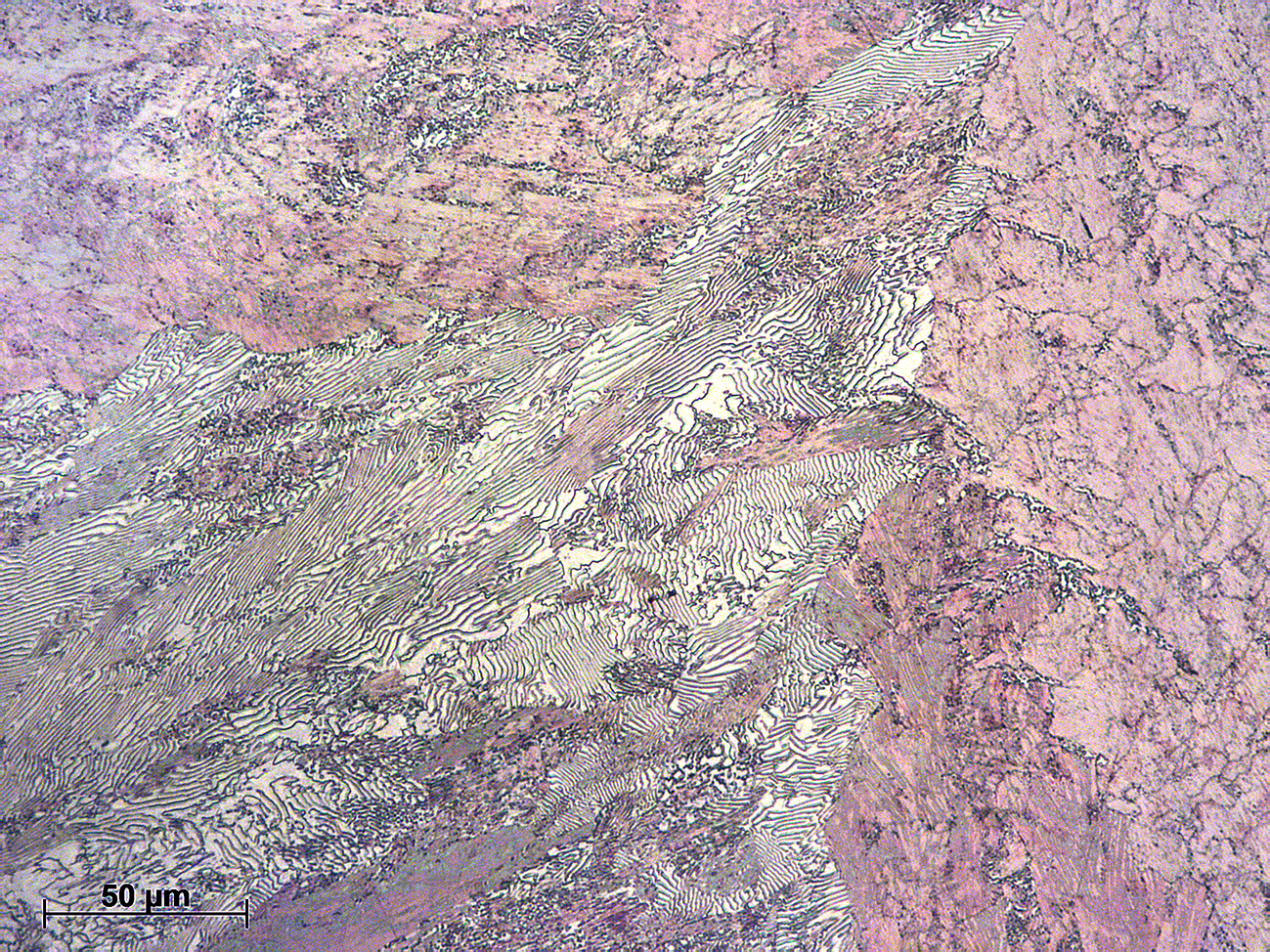

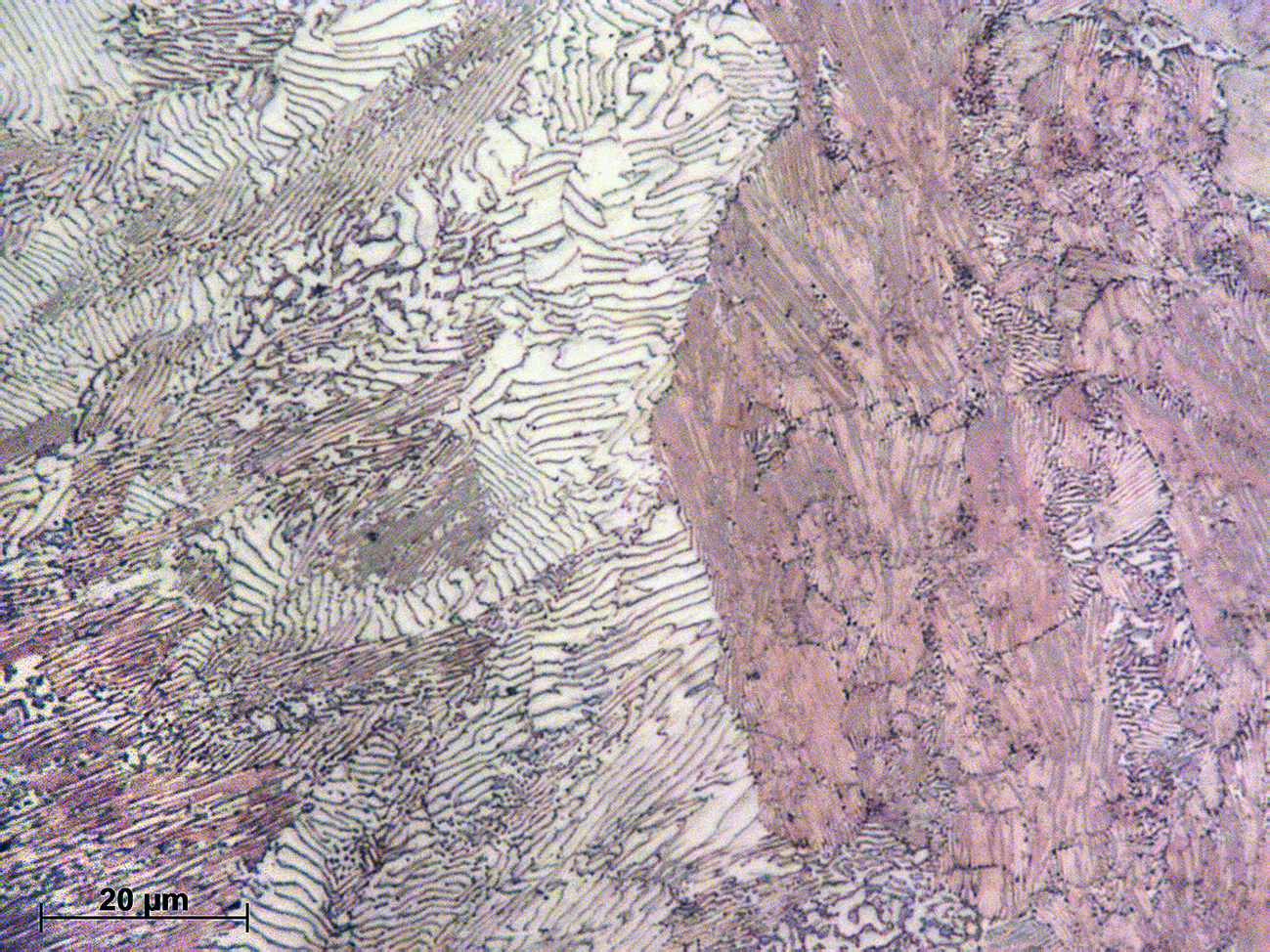

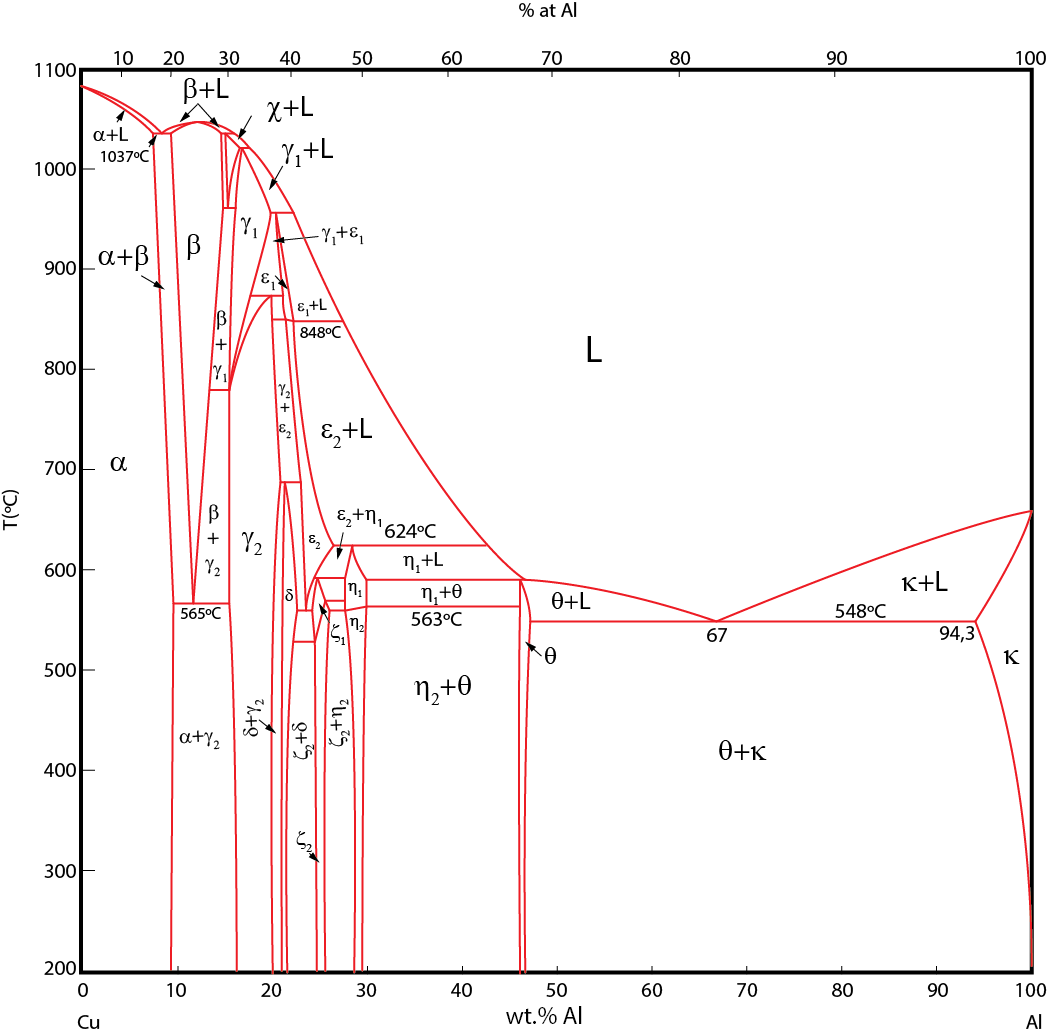

This a Cu-Al alloy of eutectoid composition. After casting, the material is heated up to 900ºC, resulting in a homogeneous equiaxial structure of β phase. Then, during slow cooling, β transforms into the lamellar aggregate α+γ2. The macrograph shows iridescent equiaxial grains due to interaction between visible light and the lamellar aggregate. The aggregate α+γ2 is also named pearlite as it resembles the eutectoid that forms in steels. The γ2 phase appears dark and discontinuous in the micrographs, whereas the α phase appears lighter.

Cu-Al diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International