X22

Cu-Al alloy (11.8%Al)

Composition: Cu-11.8%Al.

Processing: Permanent mold casting. Annealing (900ºC-1h), Slow cooling until 530ºC and Water quenching.

Etching: 5-10 s immersion in FeCl3 alcoholic solution.

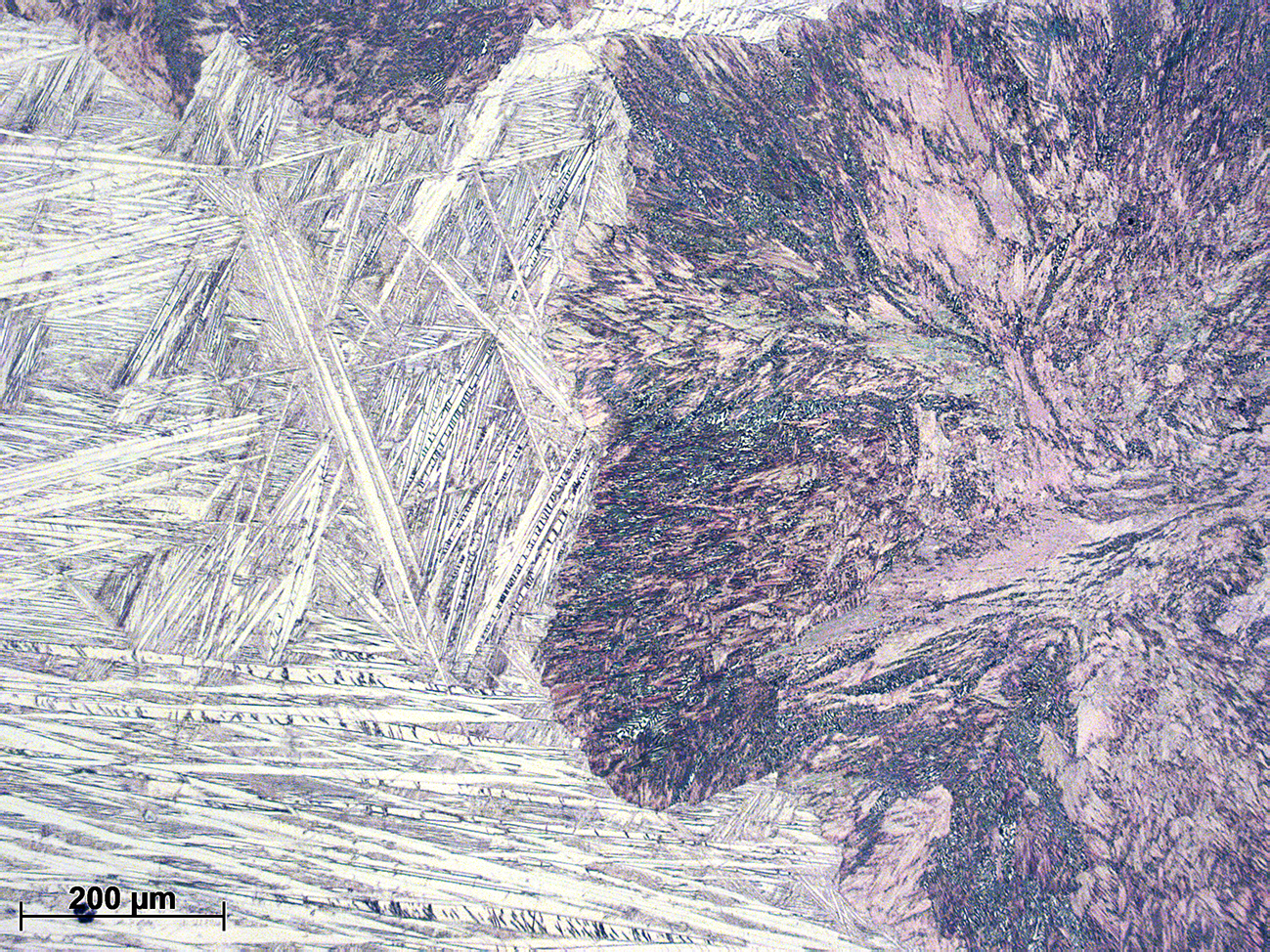

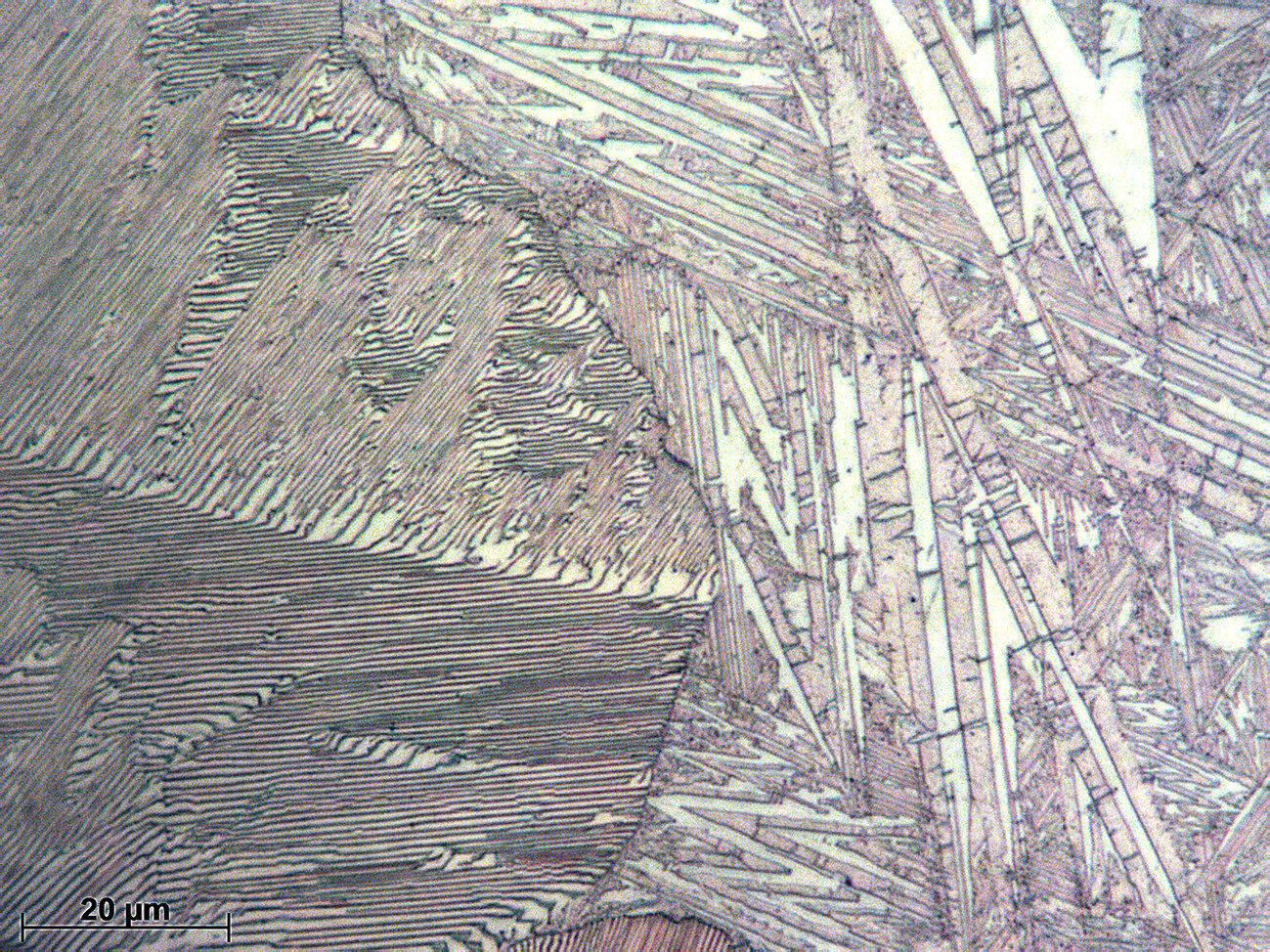

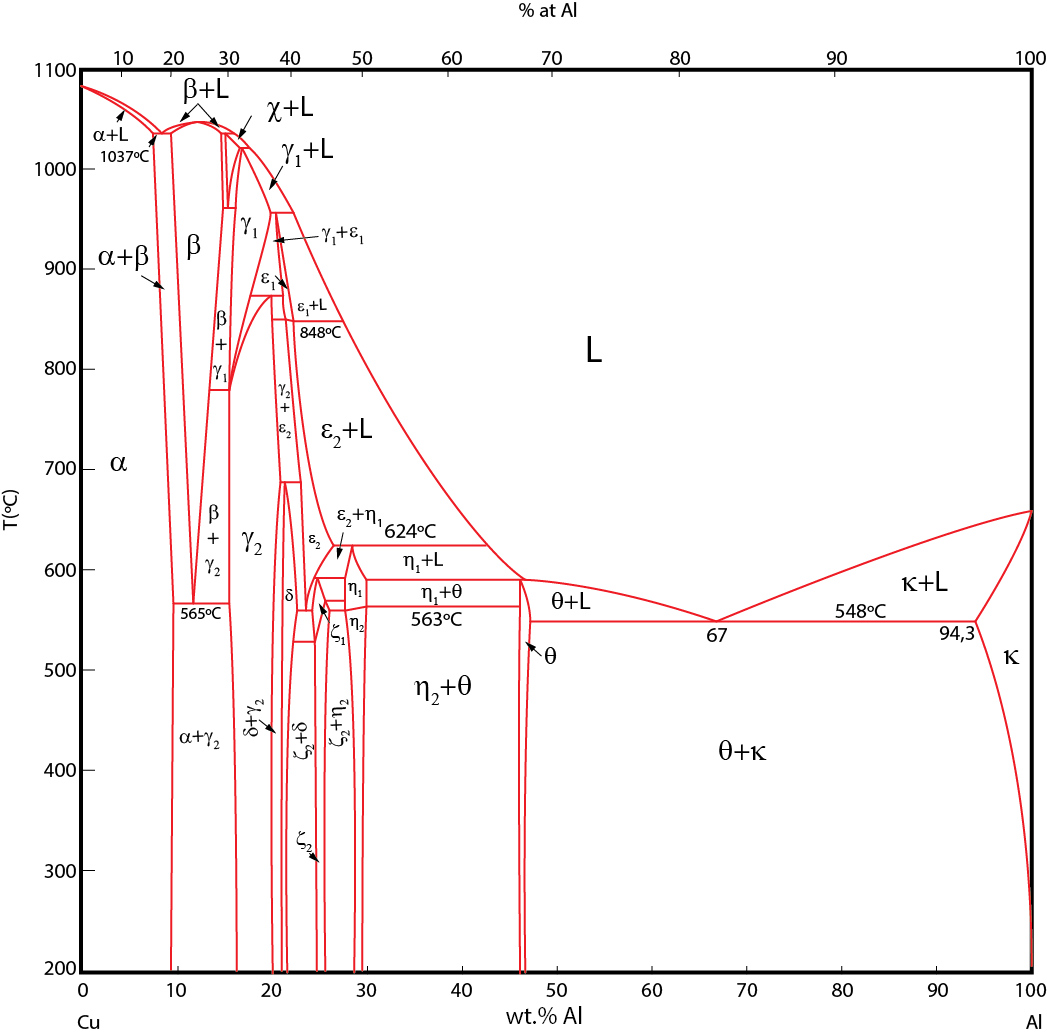

The macrograph shows large equiaxial grains (yellow) together with a spheric constituent (brown). The large grains of β phase are formed during annealing at 900ºC. Then, during slow cooling, the β phase transforms to the α+γ2 lamellar aggregate, which nucleates at the grain boundaries and growths radially. The eutectoid transformation is not completed due to the limited time before quenching from 530ºC. The remaining β phase is then transformed into the metastable β‘ martensite (supersaturated solid solution of Al in Cu). The acicular structure of β‘ martensite is very well defined in the micrographs.

Cu-Al diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International