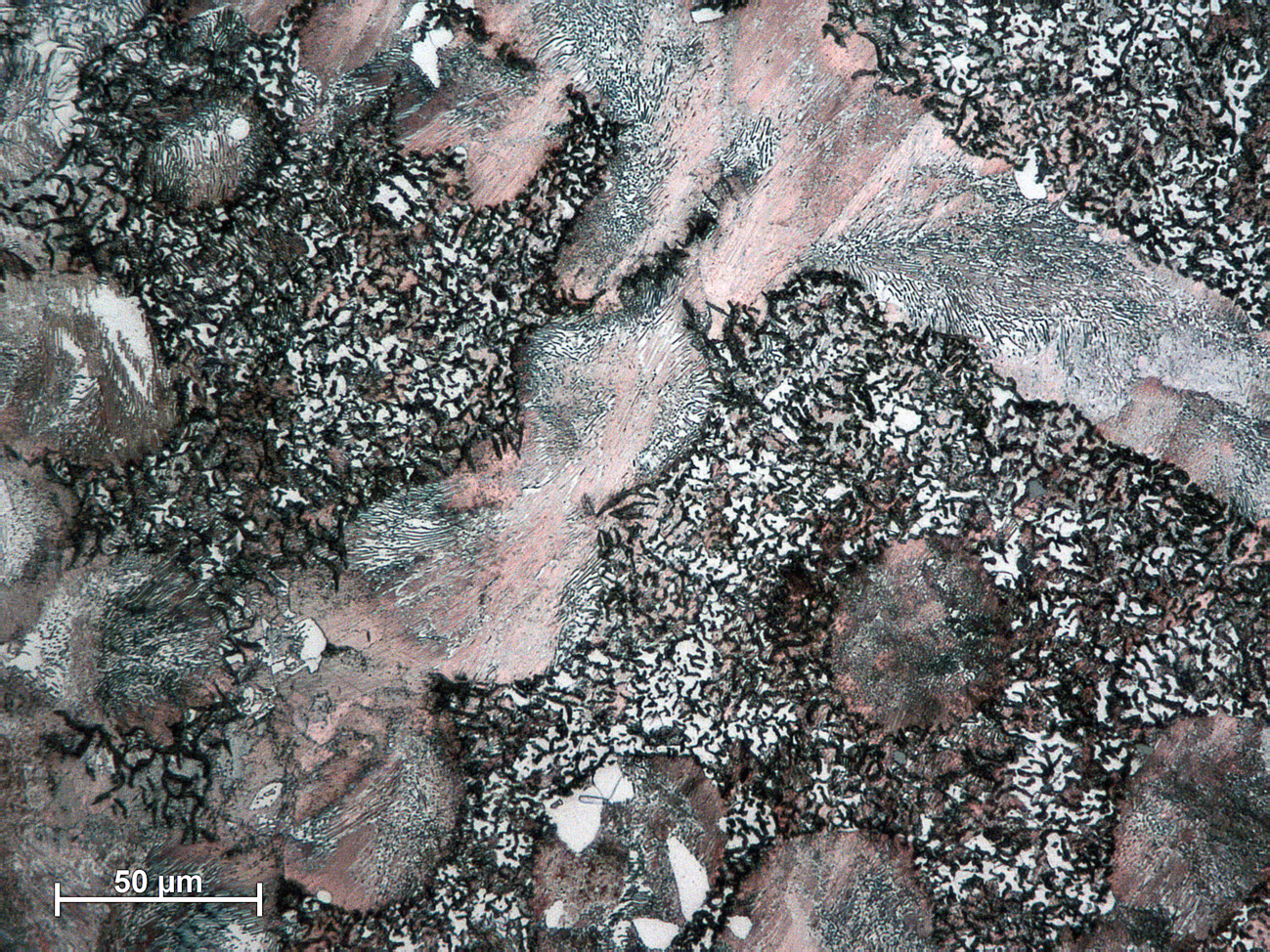

F2

Gray cast iron (graphite A and D in pearlitic matrix)

Composition: Hypoeutectic.

Processing: Casting.

Etching: 10-30s immersion in 2% nital.

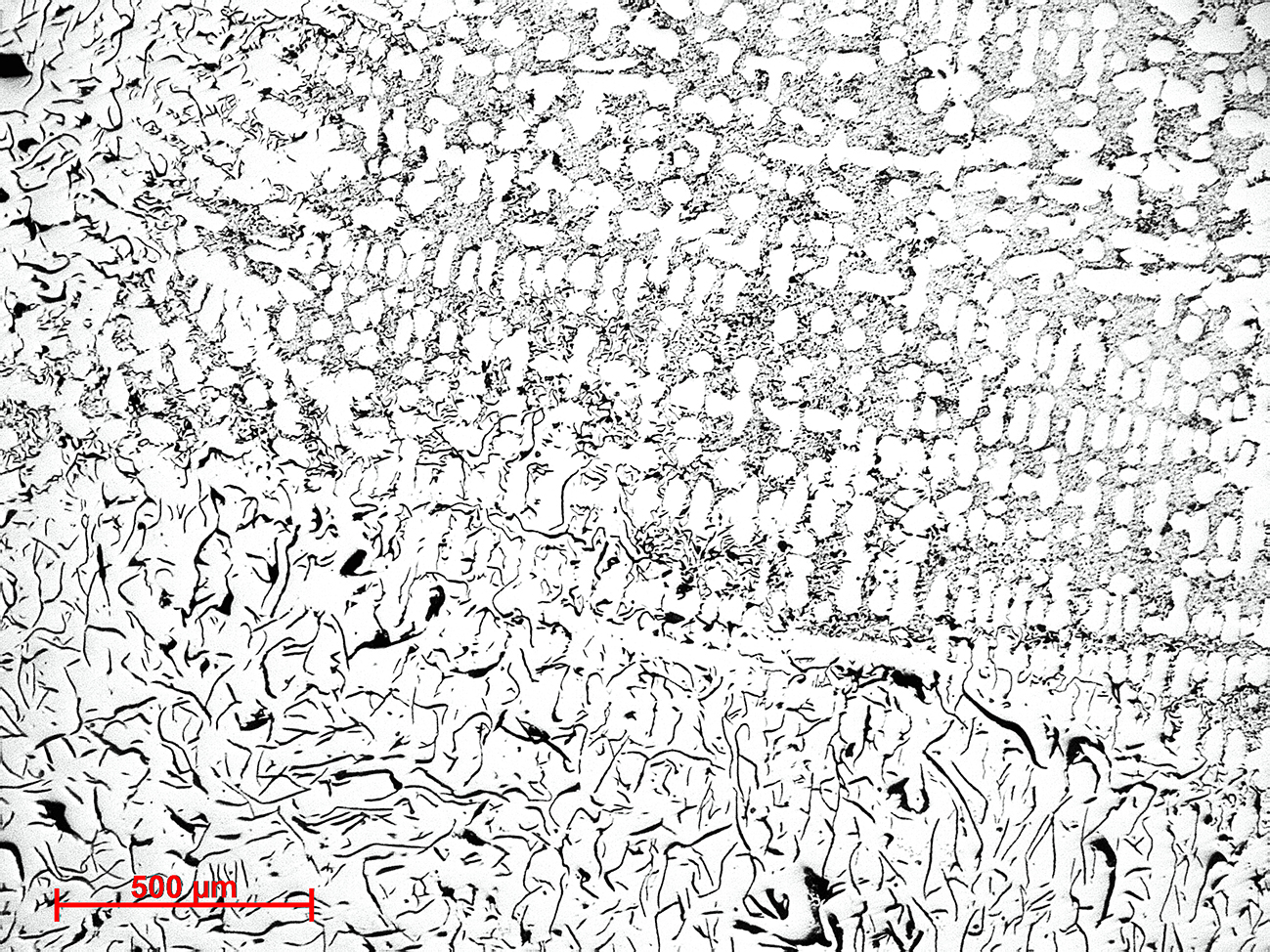

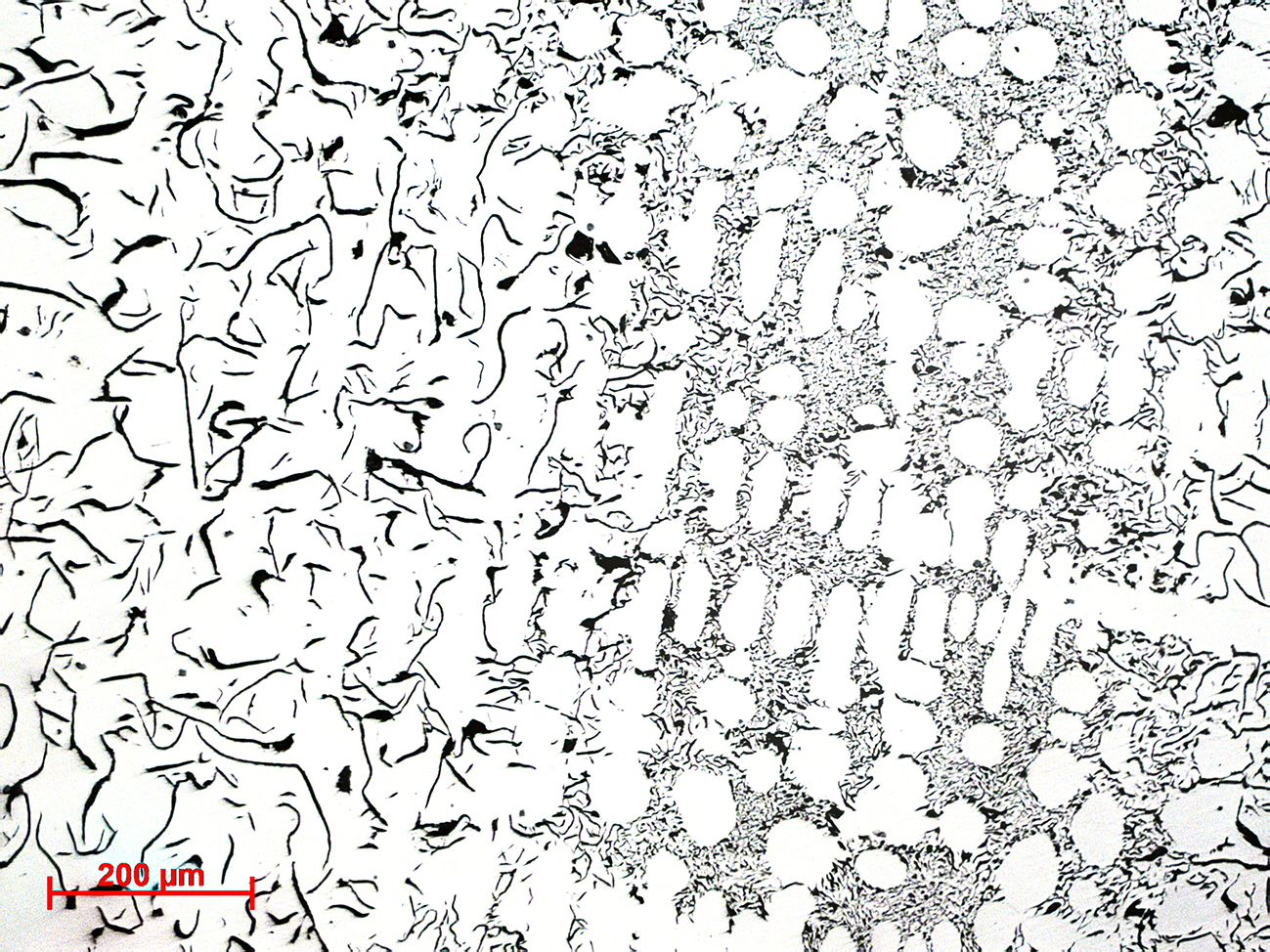

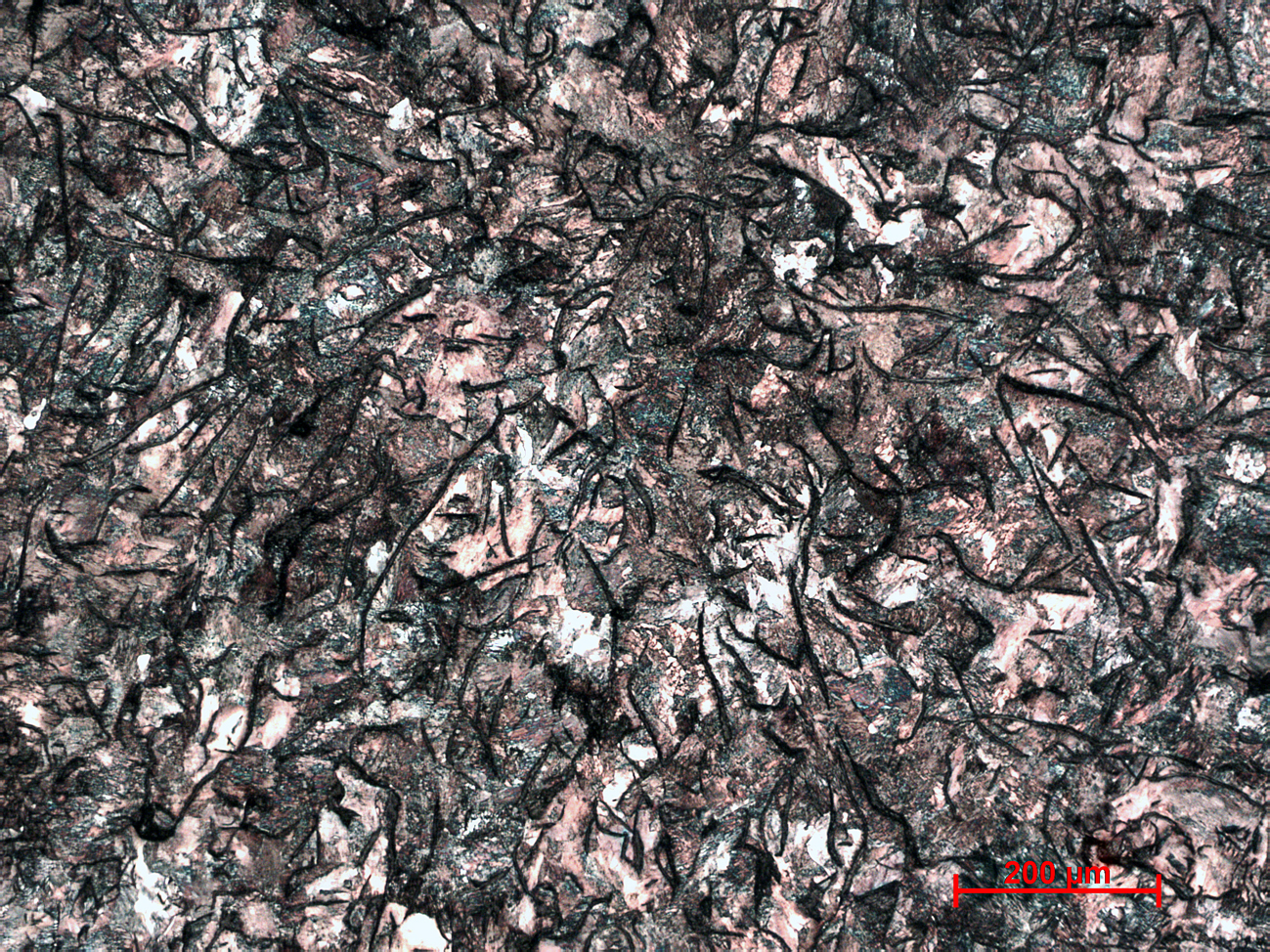

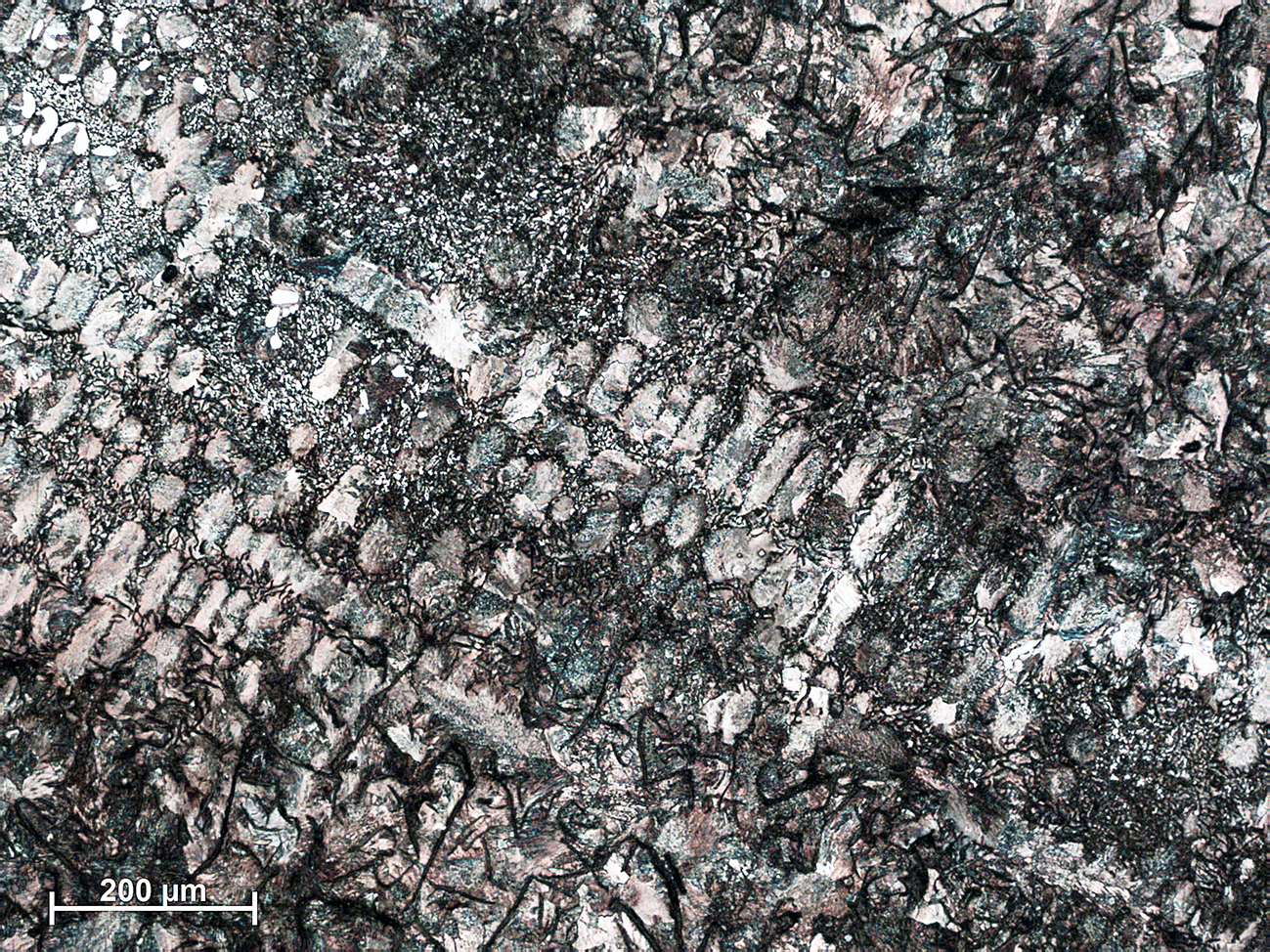

This is a cast iron with very similar composition to that of specimen F1. However, in this case, as shown in the unetched surface, there are two distinct graphite morphologies according to UNE 36117 and ASTM A247 standards:

-Type A graphite: Flakes of uniform size. Within the group of flake irons, this is the preferred type as it provides the best mechanical properties.

-Type D graphite: Small flakes or points at the interdendritic spaces of transformed austenite. This type of graphite is common in cast irons that were obtained with high cooling rates or with lack of inocculants. Its presence is common in thin specimens. This type of graphite is undesirable due the inferior mechanical properties that result from it.

Nital etch reveals the pearlitic matrix, which was formed through eutectoid transformation of austenite. The interlaminar space is smaller in this specimen when compared to the F1 specimen. This makes sense, due to the higher cooling rate in this case. In some regions, it is possible to find small ferritic regions next to the Type-D graphite. MnS inclusions and steadite are also visible, although the latter is less abundant than in F1 specimen.

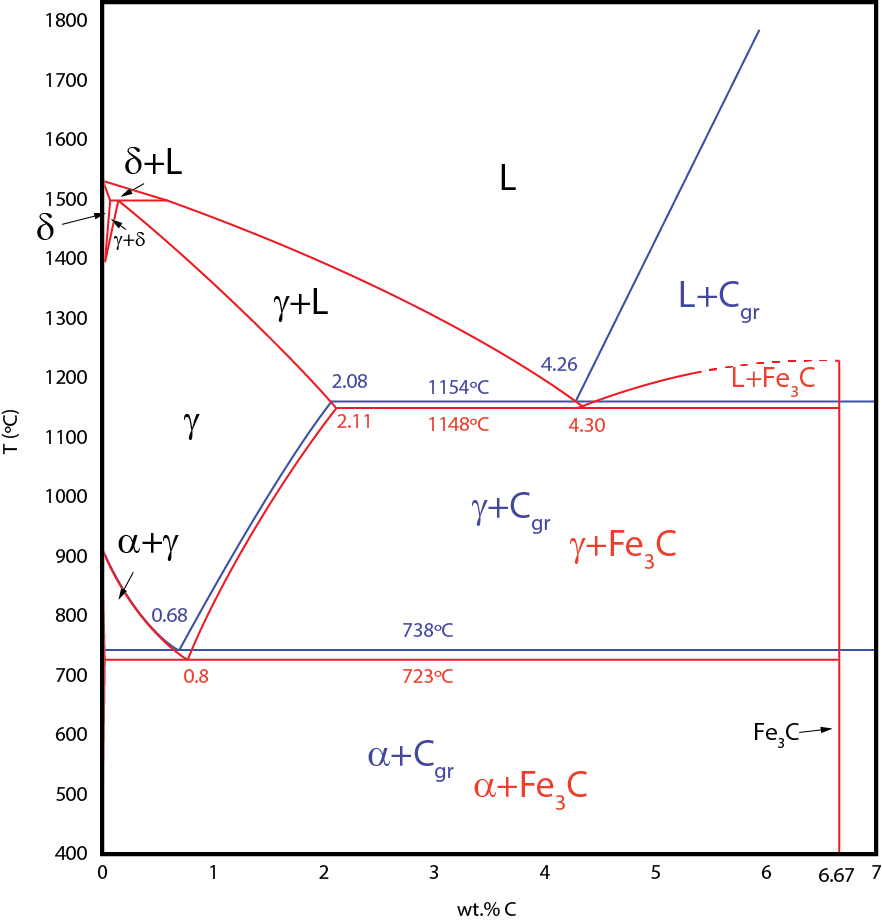

Fe-C diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.