X14

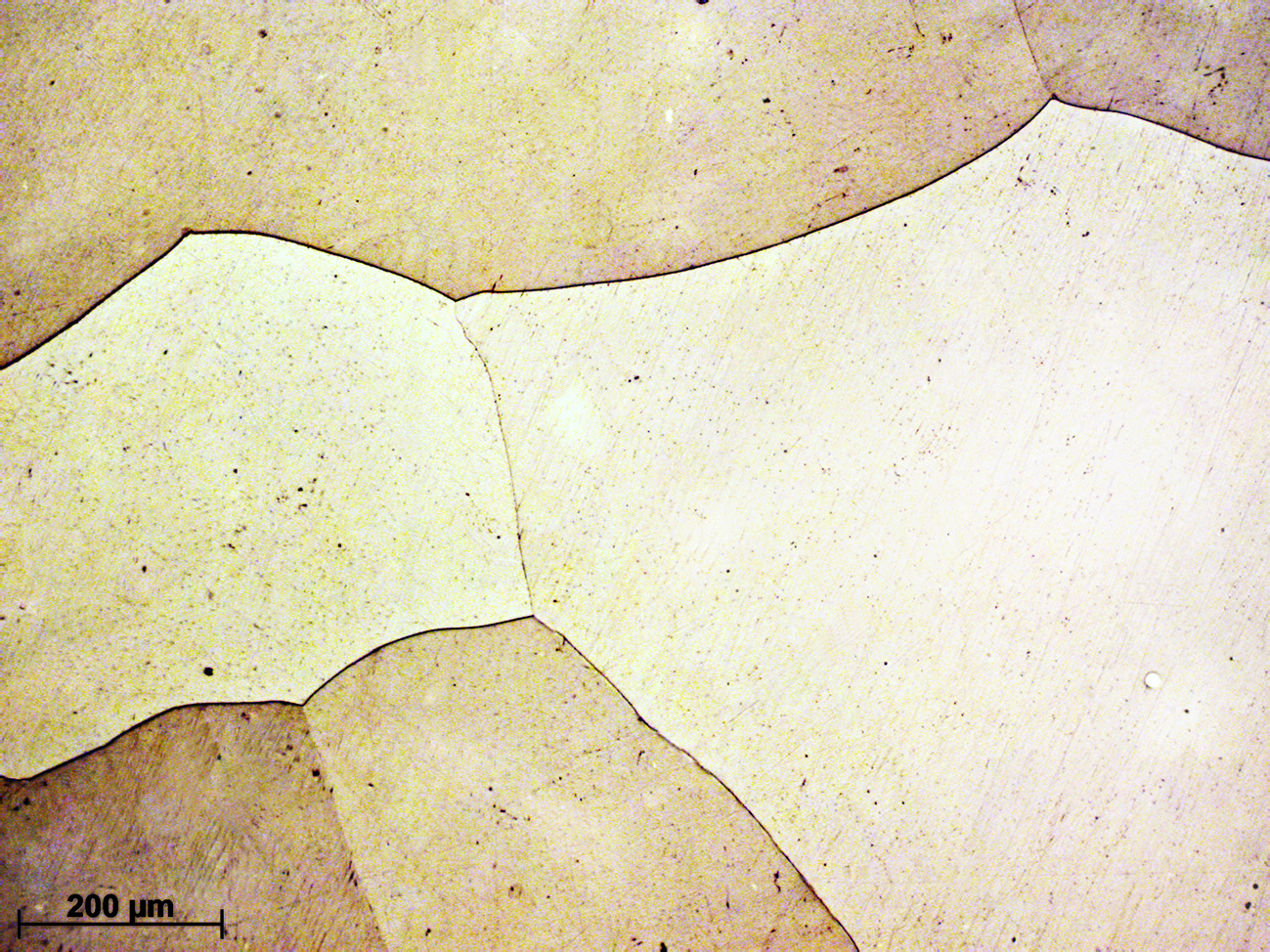

Al-Cu alloy (4%Cu) Cast-Solution heat treated-Quenched

Composition: Al-4%Cu.

Processing: Sand casting, Annealing (525 °C, 16 h) and Water quenching.

Etching: 15-20 s immersion in mixture of acids (HCl+HNO3+HF).

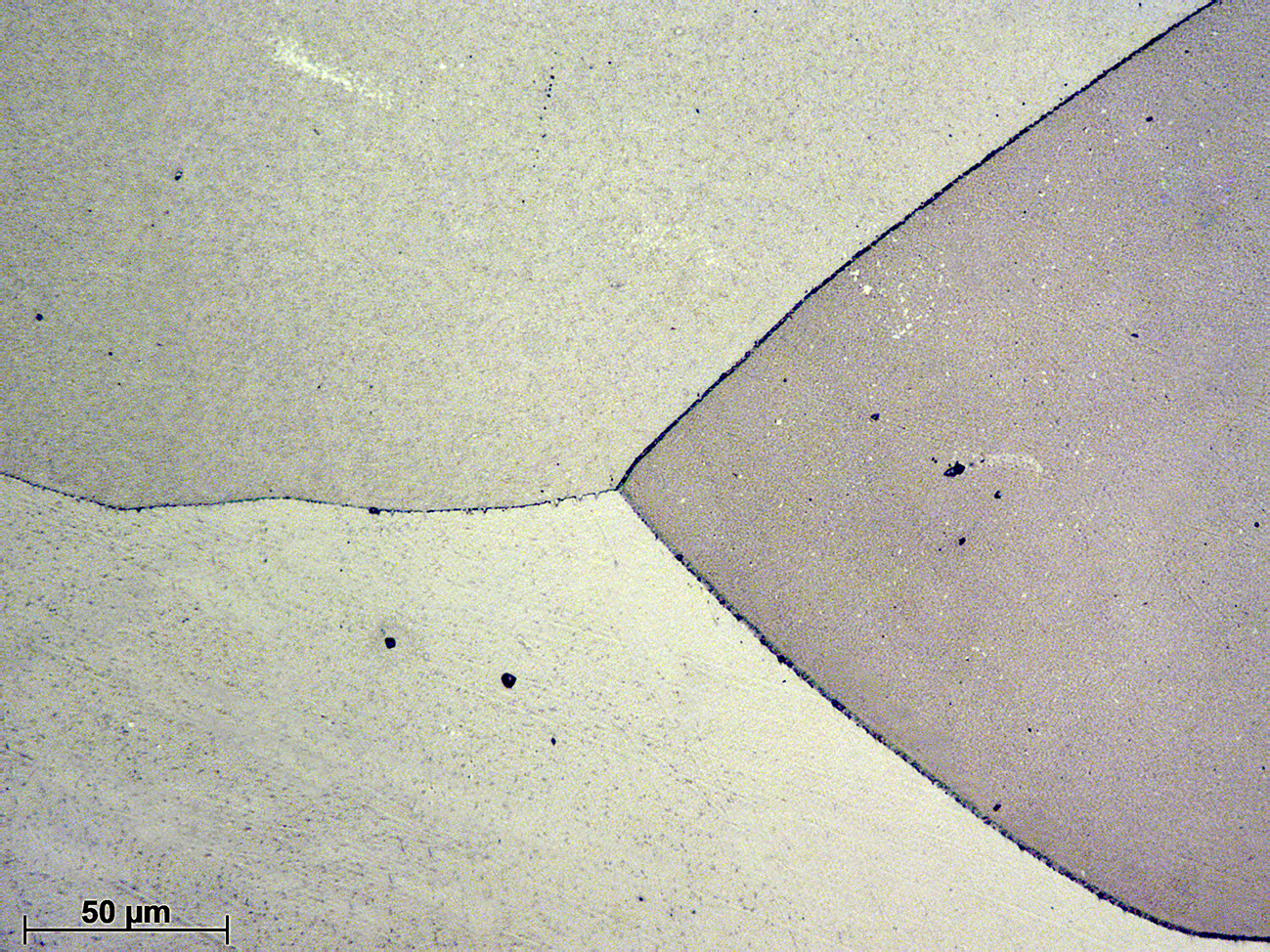

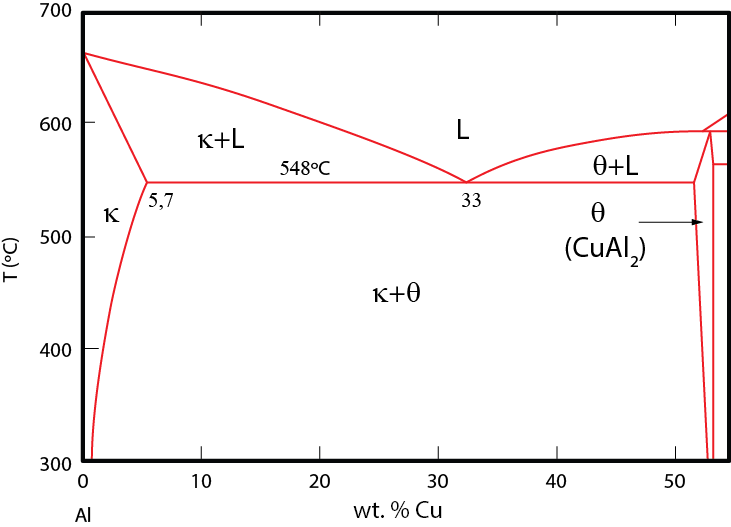

According to the Al-Cu phase diagram, annealing at 525°C brings the alloy to the monophasic κ field. As a result, dendritic segregation disappears (see X16). Quenching avoids the precipitation of the θ phase. Micrographs reveal equiaxial grains of supersaturated κ phase with a uniform distribution of copper. Grains boundaries meet at 120° due to equilibrium of surface energies.

Al-Cu diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International