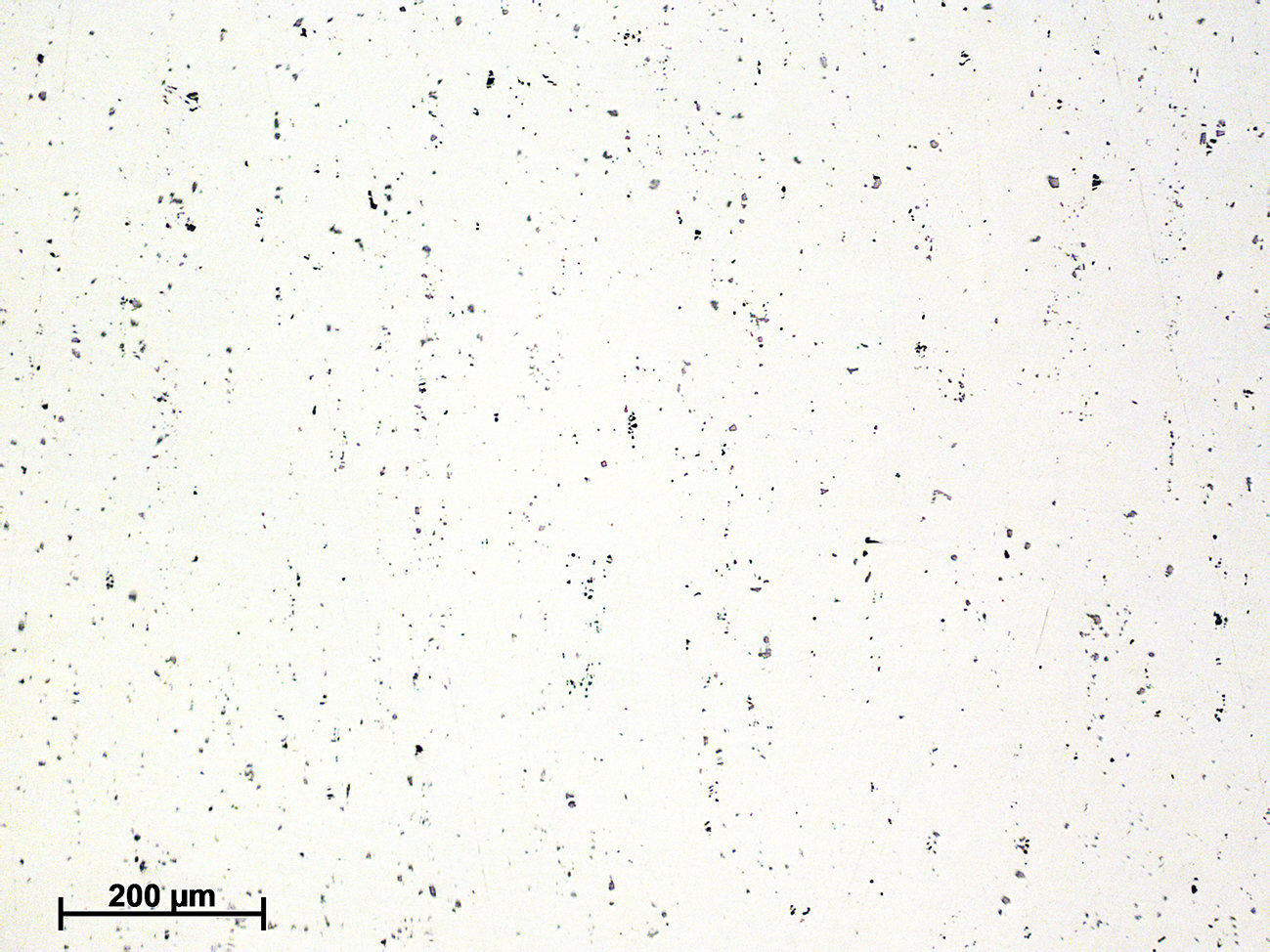

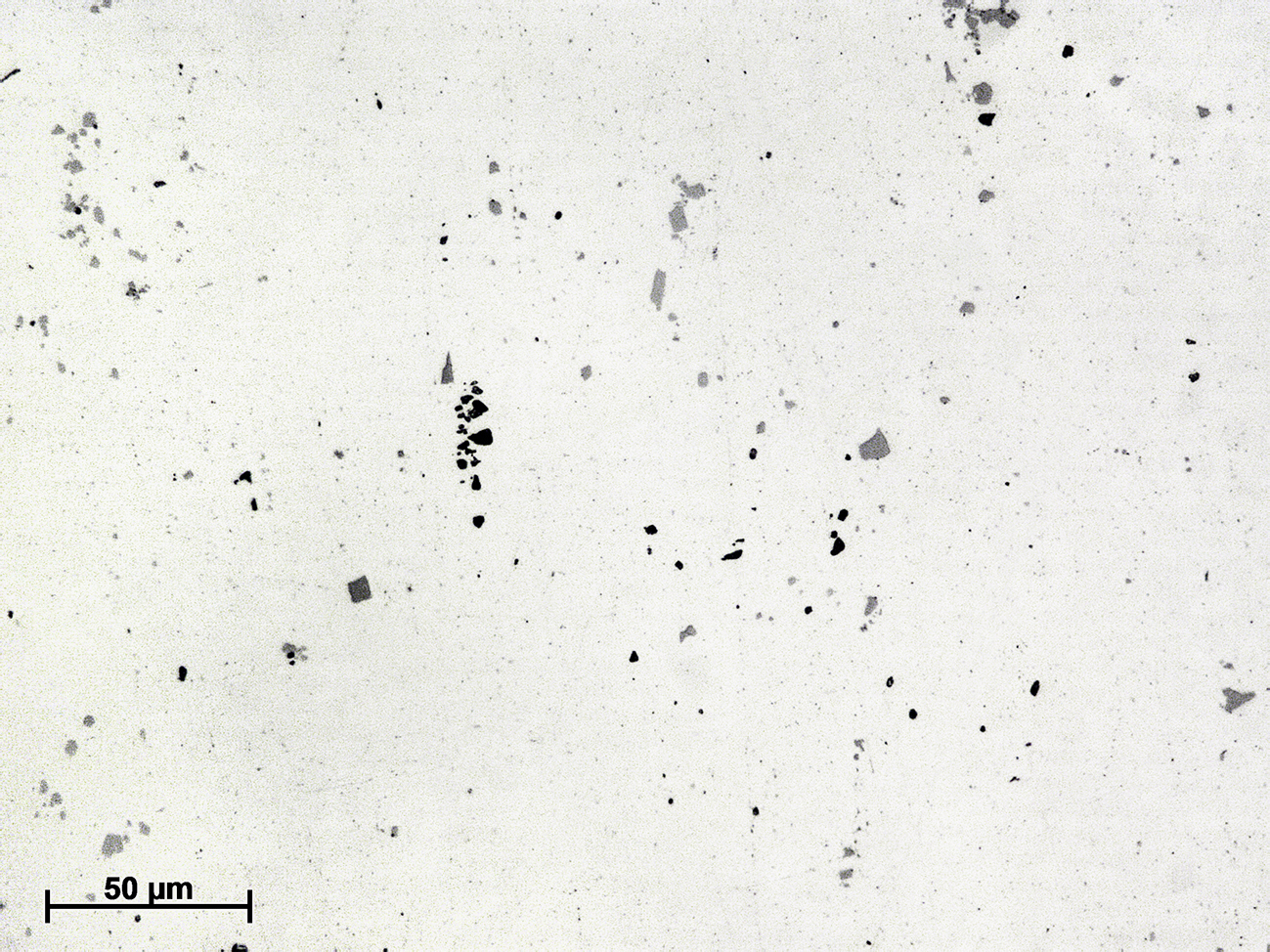

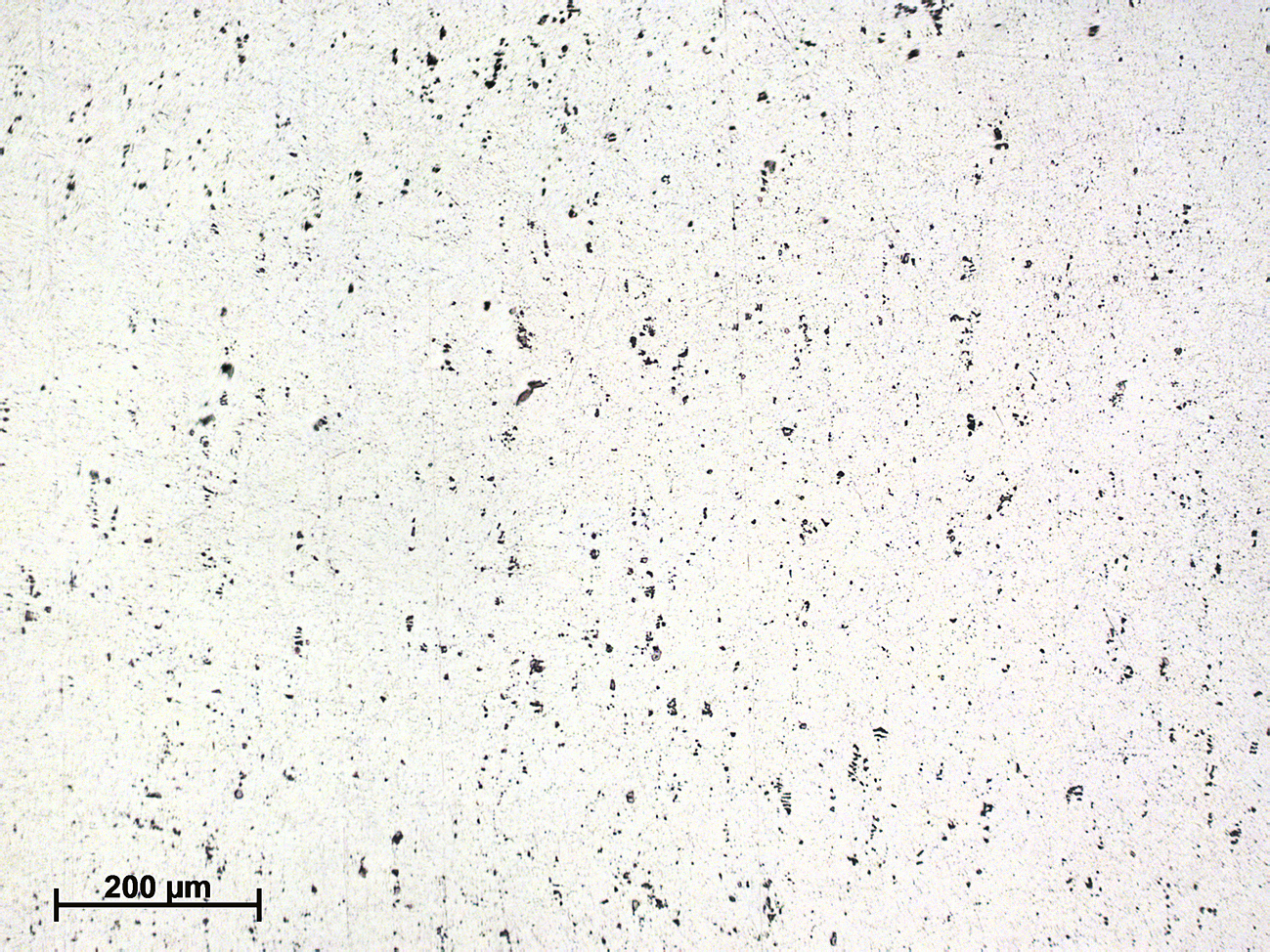

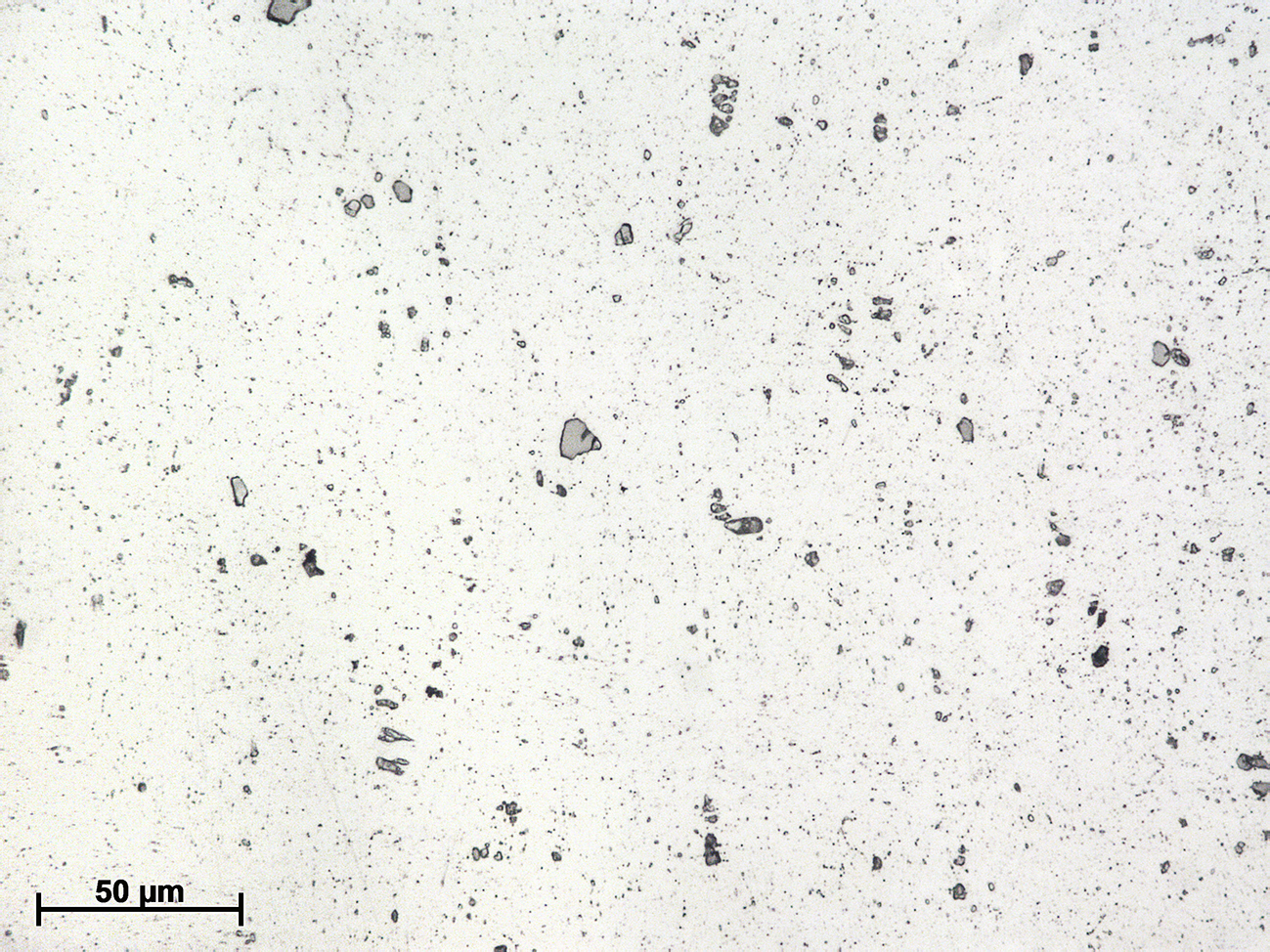

5086-ST

Al-Mg alloy, solution heat treated and quenched

Composition: 4.1 Mg; 0.45 Mn; 0.10 Cr; 0.34 Fe; 0.24 Si; 0.03 Cu; Al bal.

Processing: Forging, rolling, annealing (430 ºC - 8h) and water quenching.

Etching: 30-120 s immersion in mixture of acids (HCl+HF+HNO3).

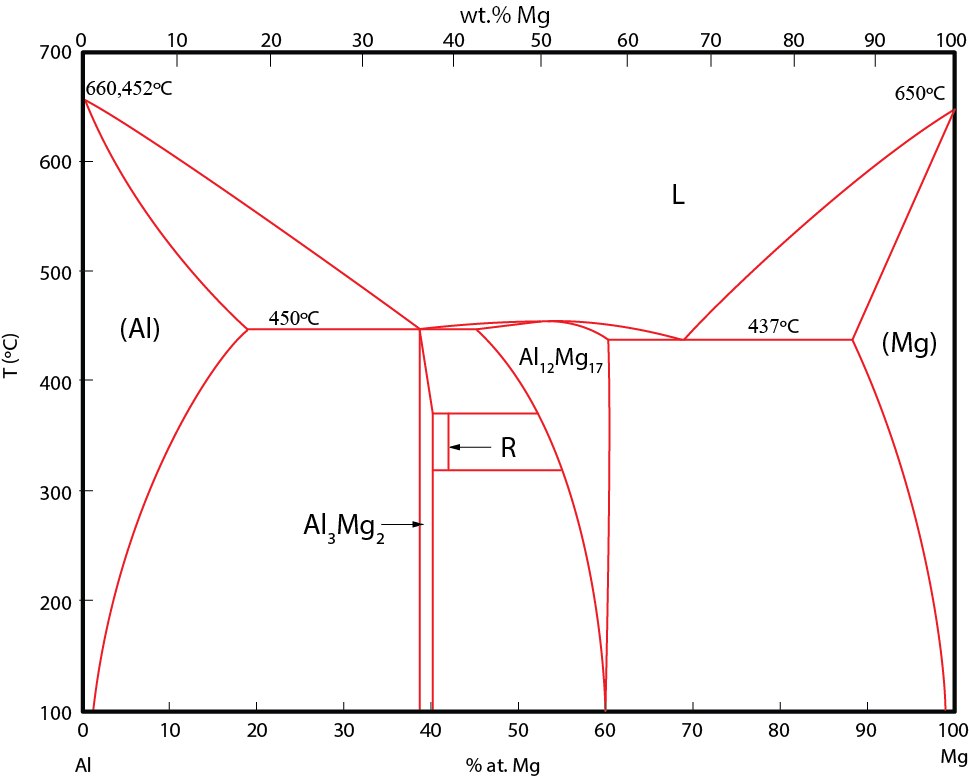

5xxx (Al-Mg) alloys are the strongest non-heat treatable aluminium alloys and they show good weldability and corrosion resistance. This is the reason why these alloys are often used for marine applications. In the non-etched specimen, two types of intermetallics aligned in the rolling direction can be differentiated: Al3Fe (gray) and Mg2Si (dark). Etching does not reveal the equiaxial α-Al grains that are present in this alloy. The reason is twofold: (i) annealing and quenching prevents the massive precipitation of Al3Mg2 at the grain boundaries, and (ii) the selected etchant does not attack the grain boundaries. 5xxx alloys are not recommeded for applications where moderate temperatures (50-200ºC) are sustained for long times due to risk of sensitization: precipitation of anodic Al3Mg2 at the grain boundaries increases the risk of intergranular and stress corrosion phenomena.

Although hardly visible, this alloy also contains dispersoids (Al6(Cr,Mn), Al18Mg3Cr2), which are used to control the grain size.

Al-Mg diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.