AZ80

Mg-8Al alloy

Composition: Mg-8,2%Al-0,46%Zn-0,13%Mn-0,01%Si-<0,001%Cu-0,004%Fe, <0,30%other

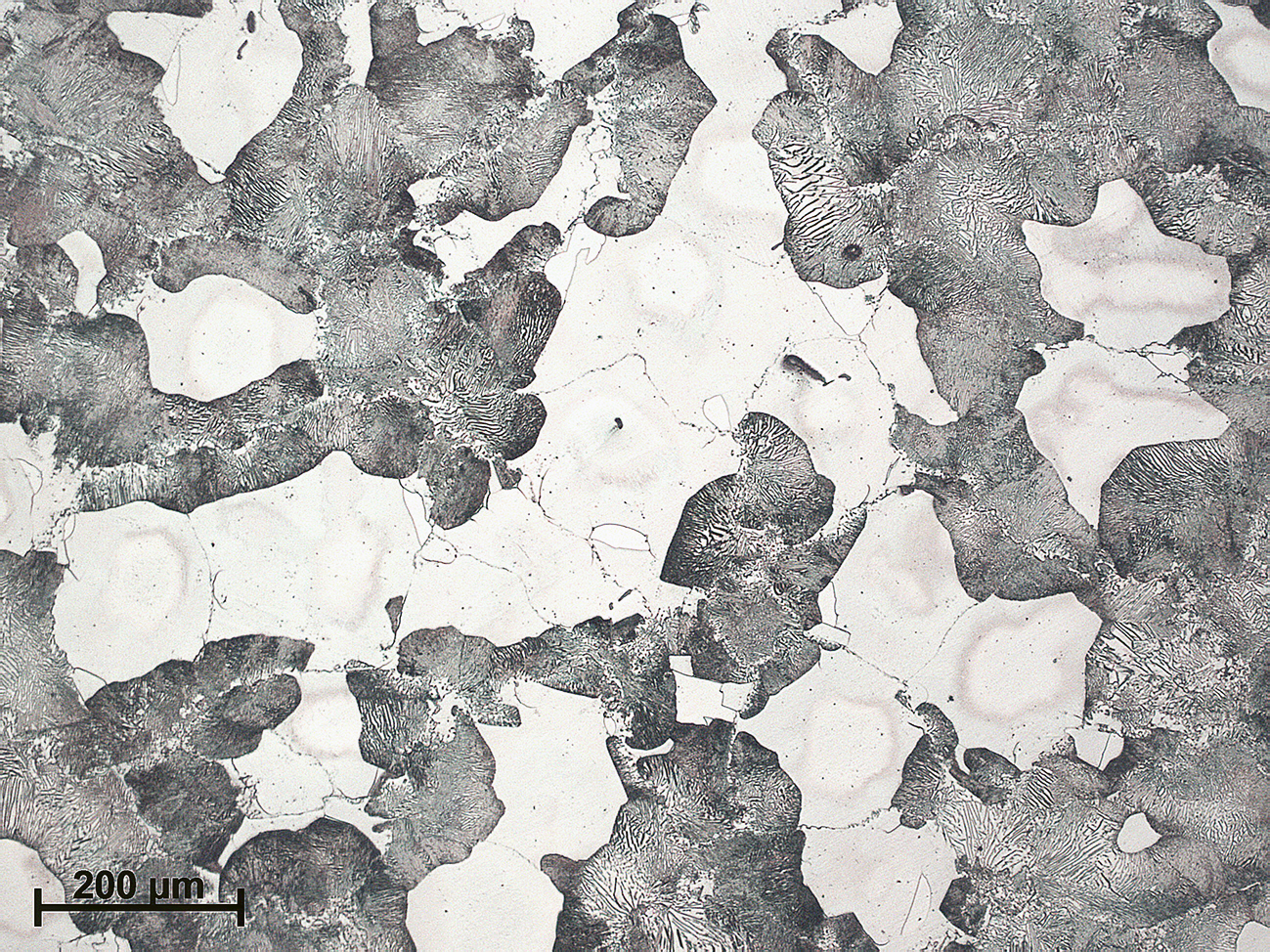

Processing: Homogenizing heat treatment to produce grain size smaller than 200 μm

Etching: 10-30s immersion in 2% nital.

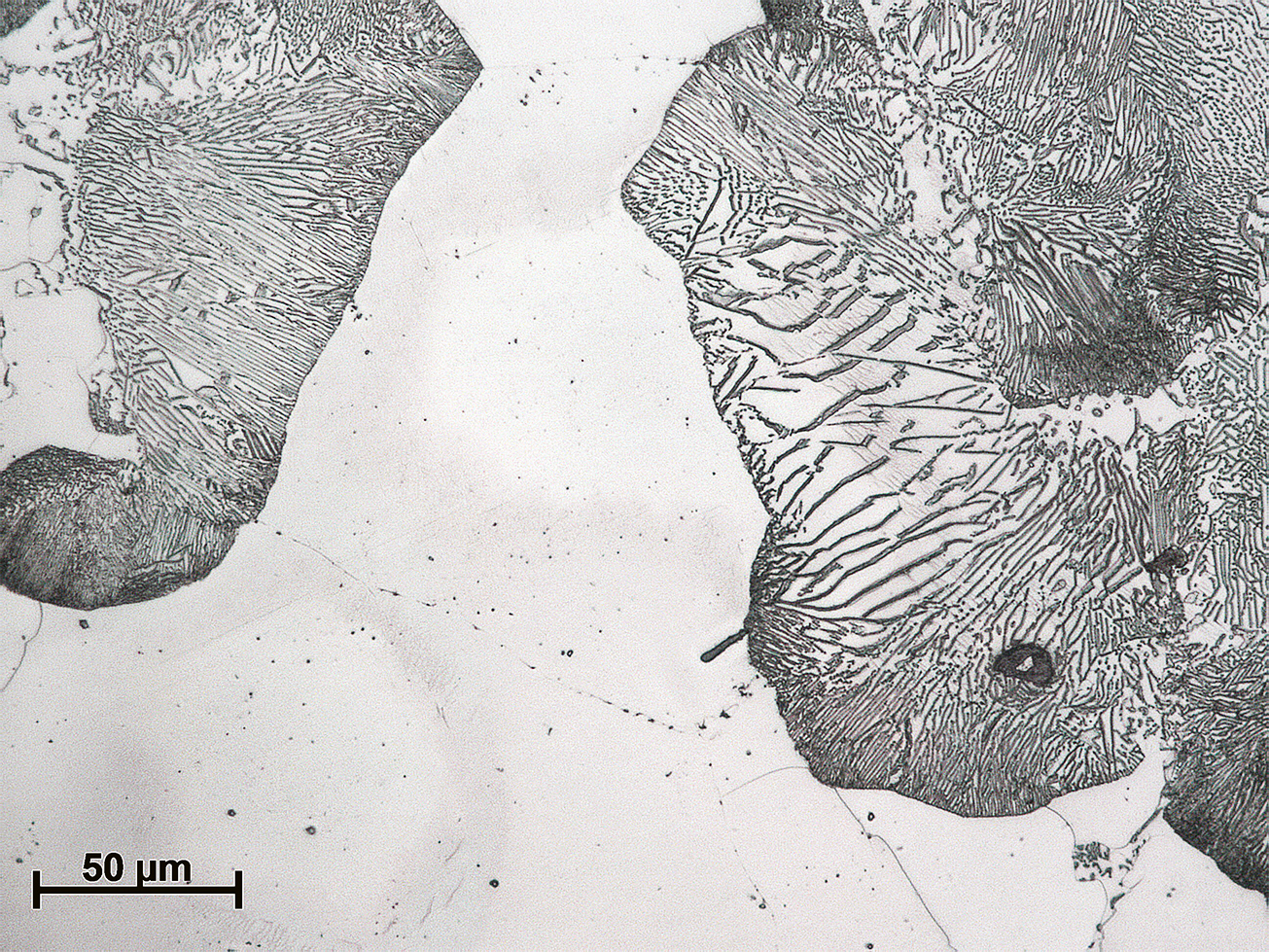

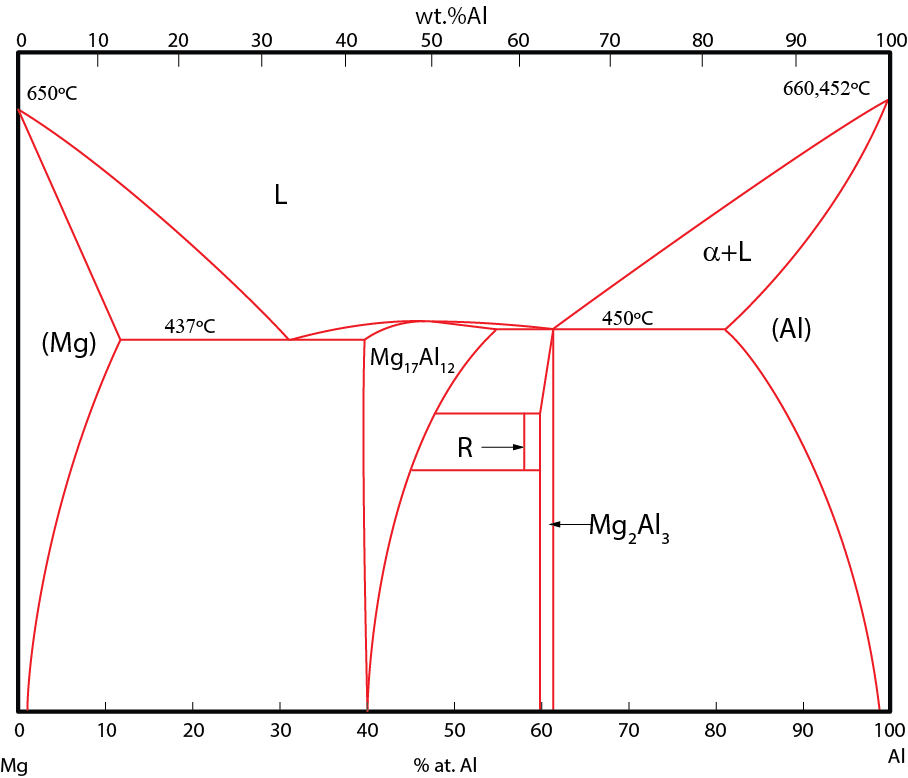

The alloy shows a microstructure consisting of α-Mg grains and a lamellar aggregate of α-Mg + β-Mg17Al12, which predominates the structure. This aggregate is formed by a cellular-type transformation in solid state. The transformation begins at the grain boundaries and the mechanism is quite different from allotriomorphic and Widmanstätten precipitation (e.g. X24 and X10). In the cellular transformation, the grain boundary of the α-Mg phase moves along with the growing lamellas of β-Mg17Al12 precipitate; the continous grain boundary is the main diffusion path for the aluminium atoms that incorporate into the secondary phase. Morphologically, the aggregate ressembles the product of a eutectoid reaction, however, the reaction is of the following nature: α (oversaturated solid soultion) → α-Mg + β-Mg17Al12. This transformation is common in slowly cooled Mg-Al alloys and the reason for it is not very clear.

One last feature is the presence of Al-Mn intermetallics, which are visible in the α-Mg grains and at the regions with the lamellar aggregate.

Mg-Al diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.