X16

Al-Cu alloy (4%Cu) Casting

Composition: Al-4%Cu.

Processing: Sand casting.

Etching: 15-20 s immersion in mixture of acids (HCl+HNO3+HF).

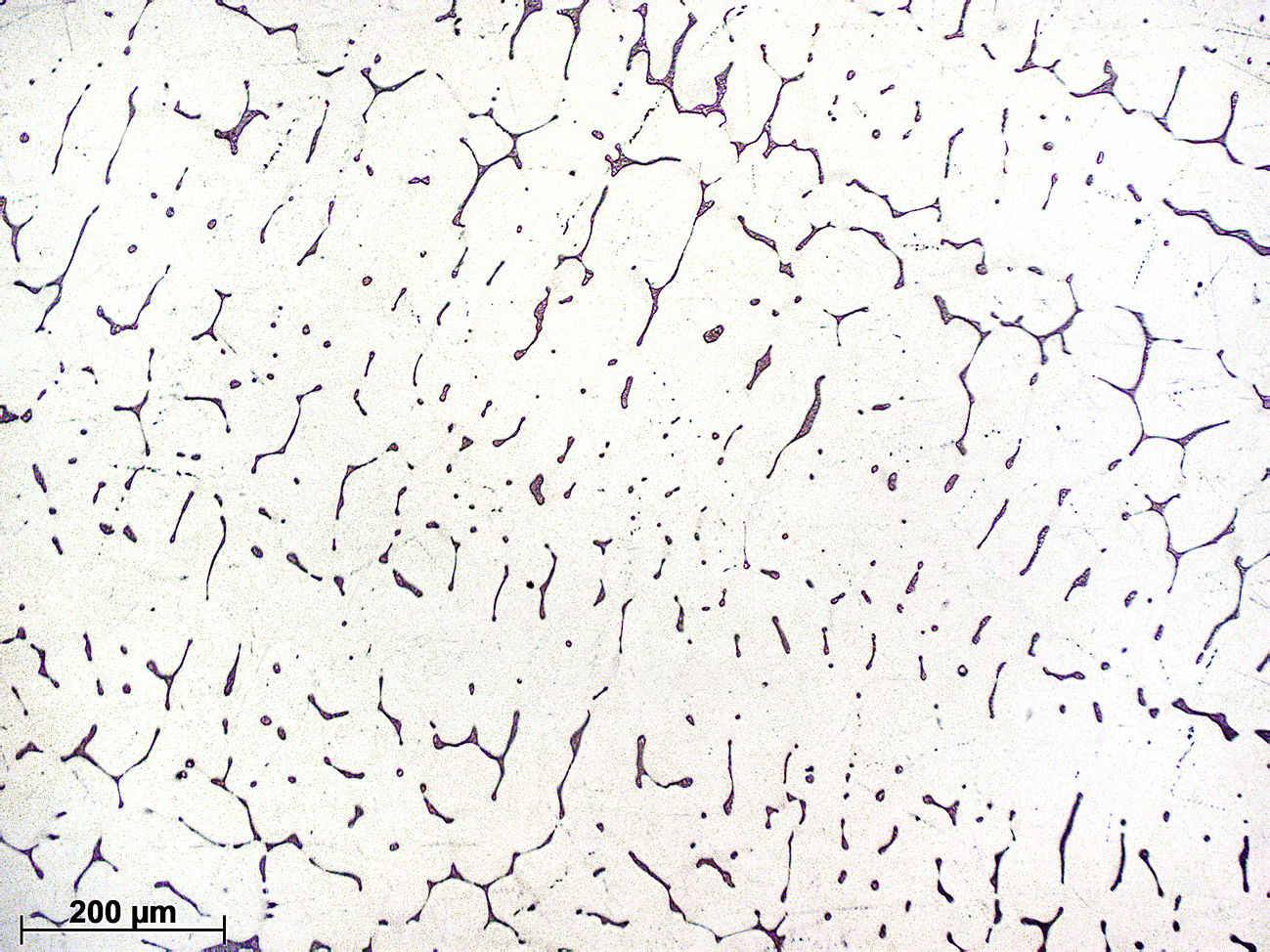

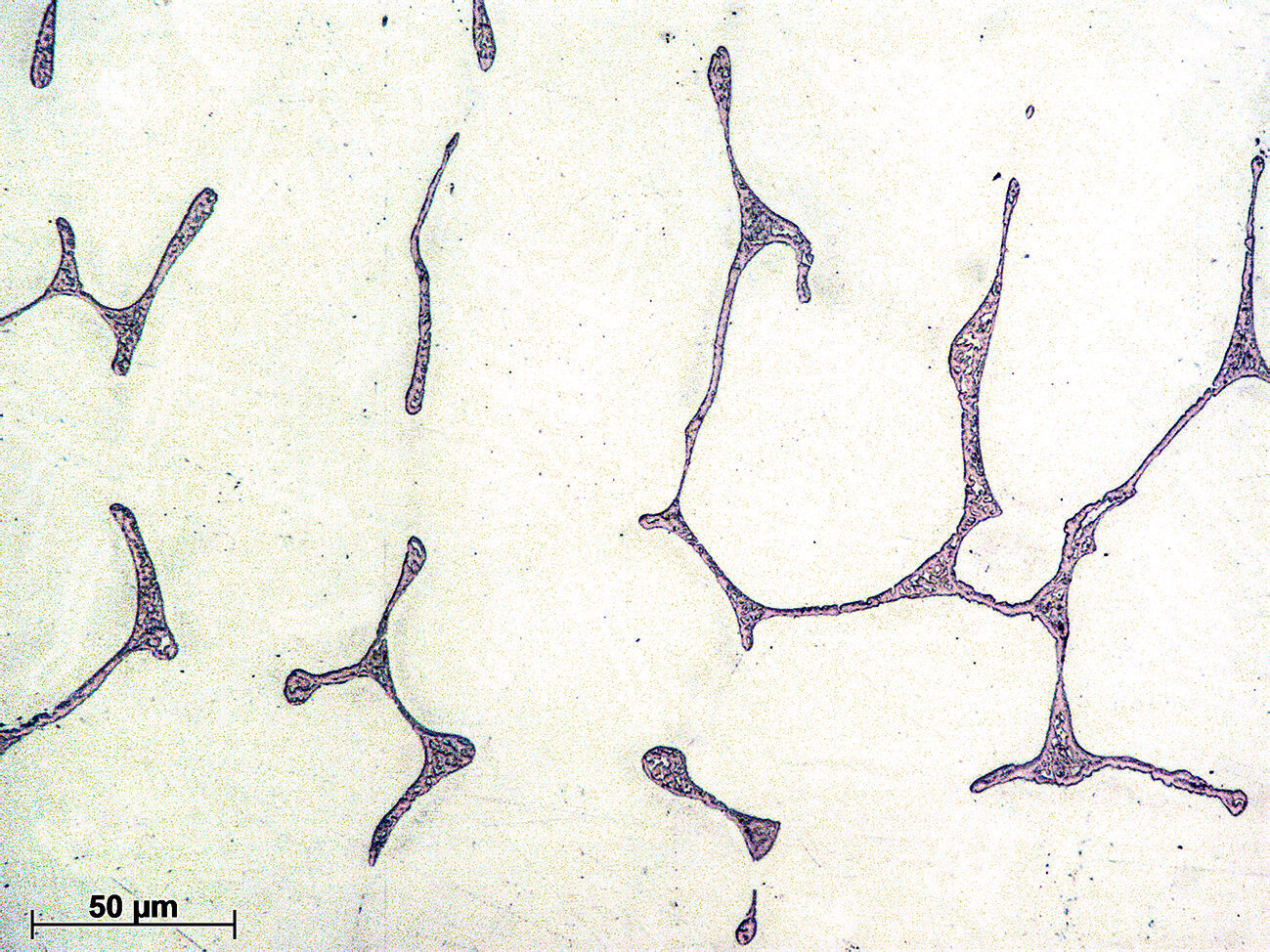

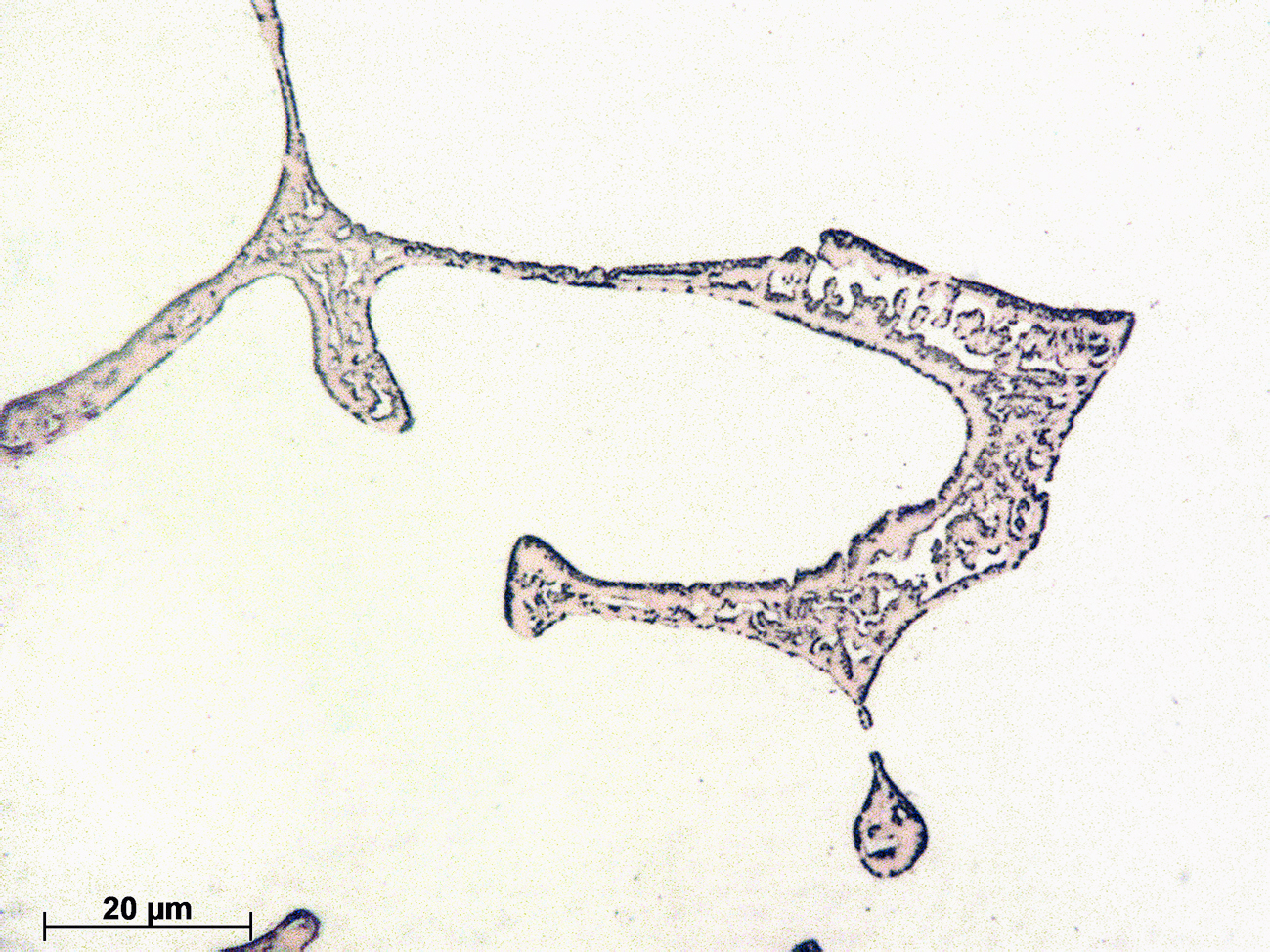

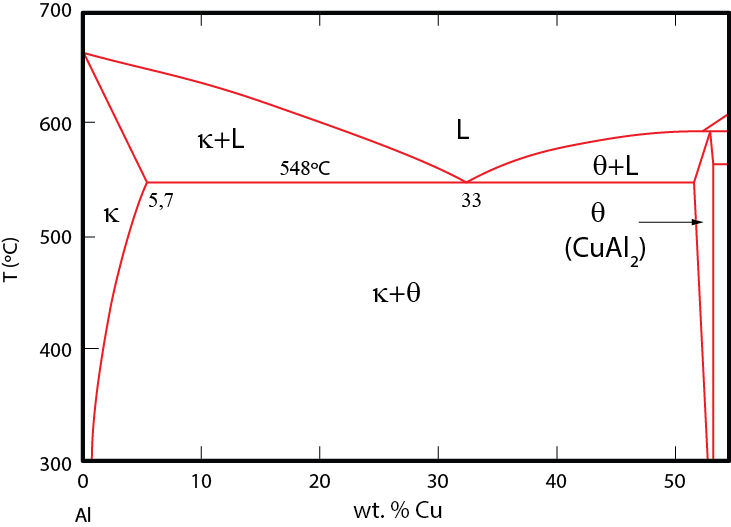

The composition of this alloy is the same as that of X14 and X15. However, this is an as cast specimen without heat treatment. According to the phase diagram, the κ phase is the first one to nucleate from the liquid. Its dendritic shape can be seen in the micrographs. The dendrites nucleate at the mold walls and at the bulk of the molten material, mostly resulting in equiaxial grains. Due to the fast cooling conditions, which are favoured by the high thermal conductiviy of aluminium, there is segregation in the κ phase and the liquid reaches the eutectic composition, resulting in a eutectic aggregate of θ + κ. This microconstituent partially surrounds the primary κ dendrites. This cast microstructure, which mainly consists of grains of κ phase, is the one that was solution heat treated at 525 °C to produce X14 and X15 specimens. Ideally, the cooling conditions should have been adjusted to minimize large quantities of eutectic, thus facilitating the solution heat treatment.

Al-Cu diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International