F7

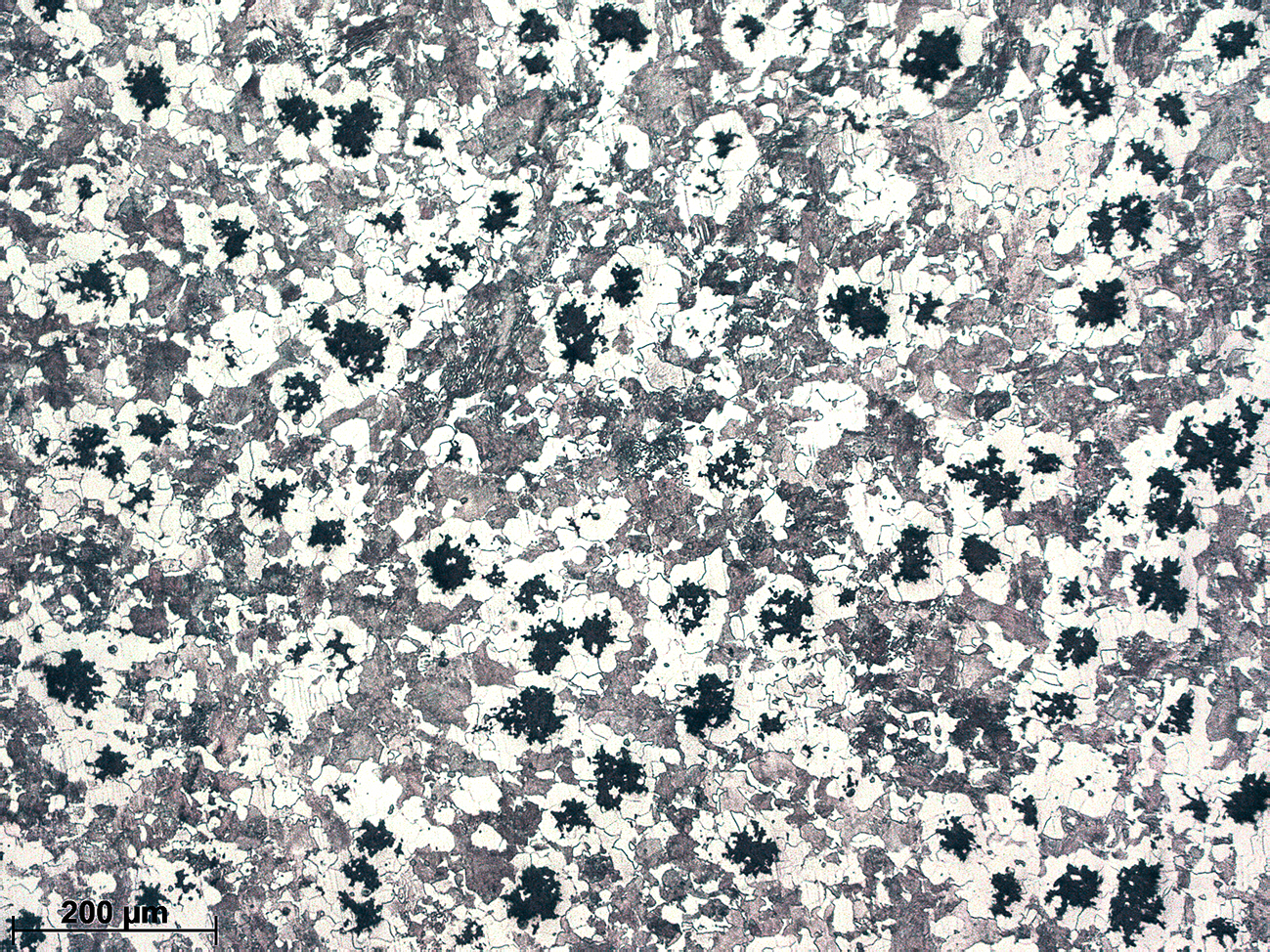

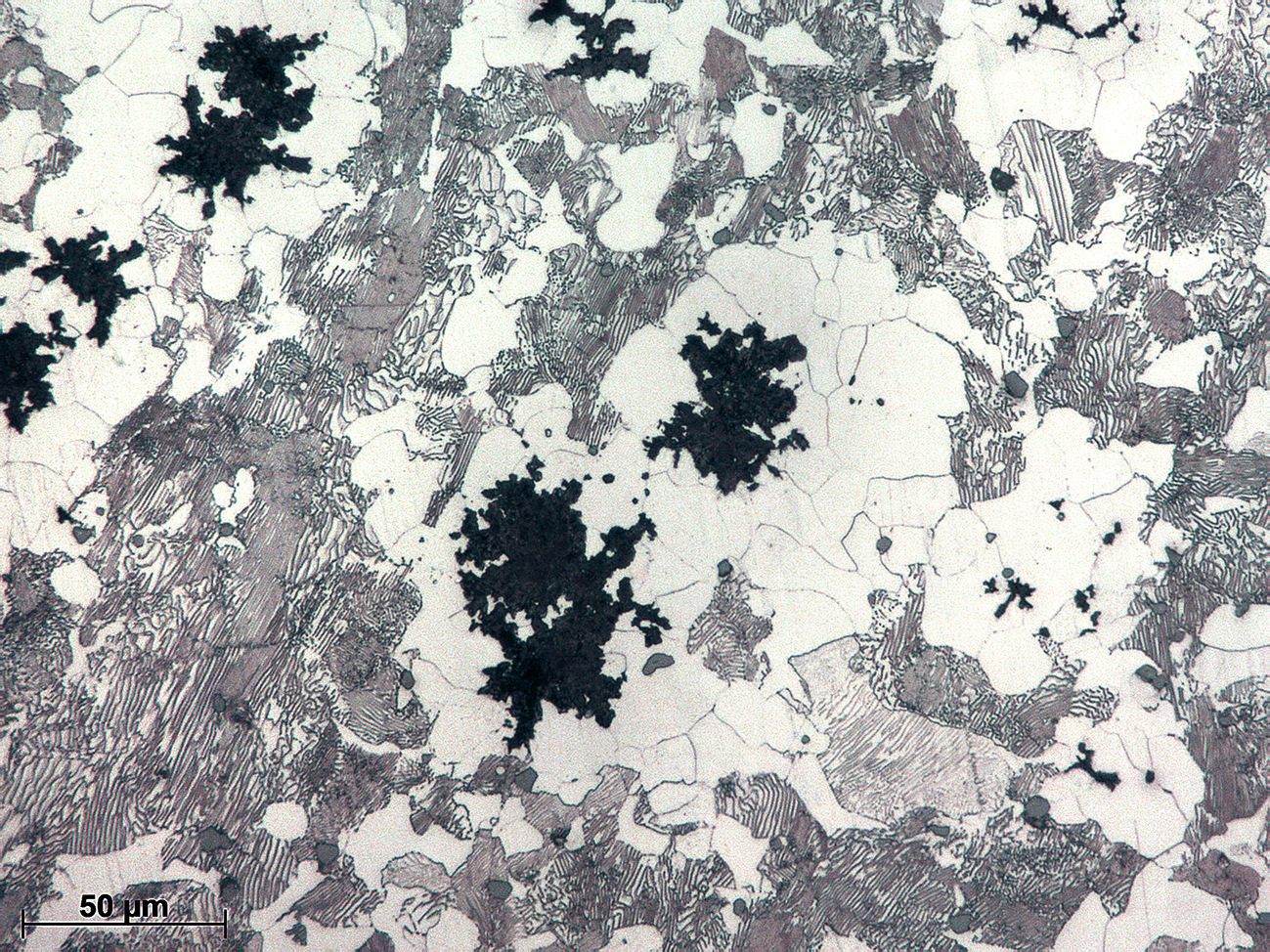

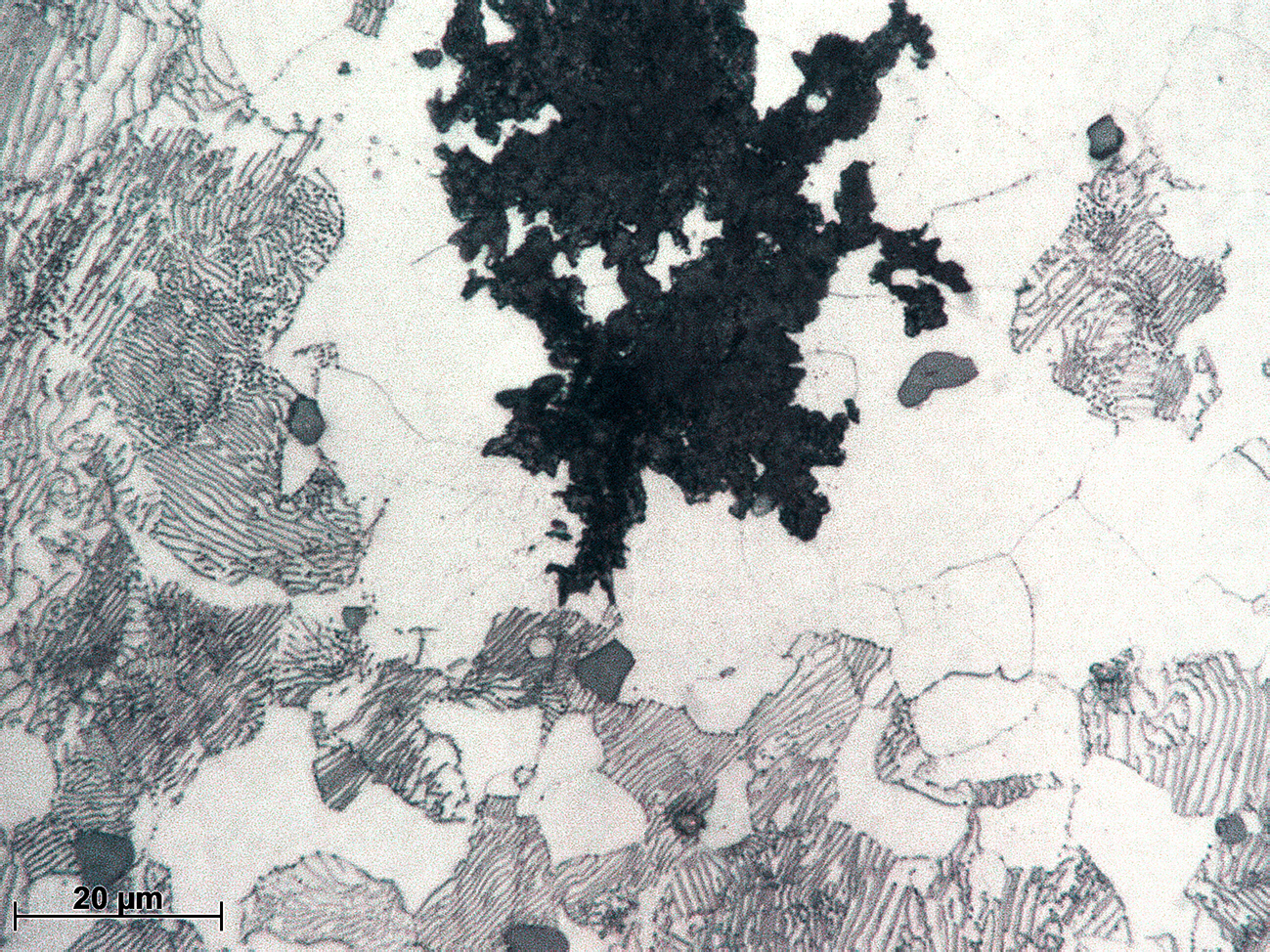

Blackheart malleable iron

Composition: Blackheart malleable iron (2,80% C; 1,20% Si; 0,40% Mn; 0,10% S; 0,05% P).

Processing: Sand casting. Malleabilization.

Etching: 10- 30 s immersion in 2% nital.

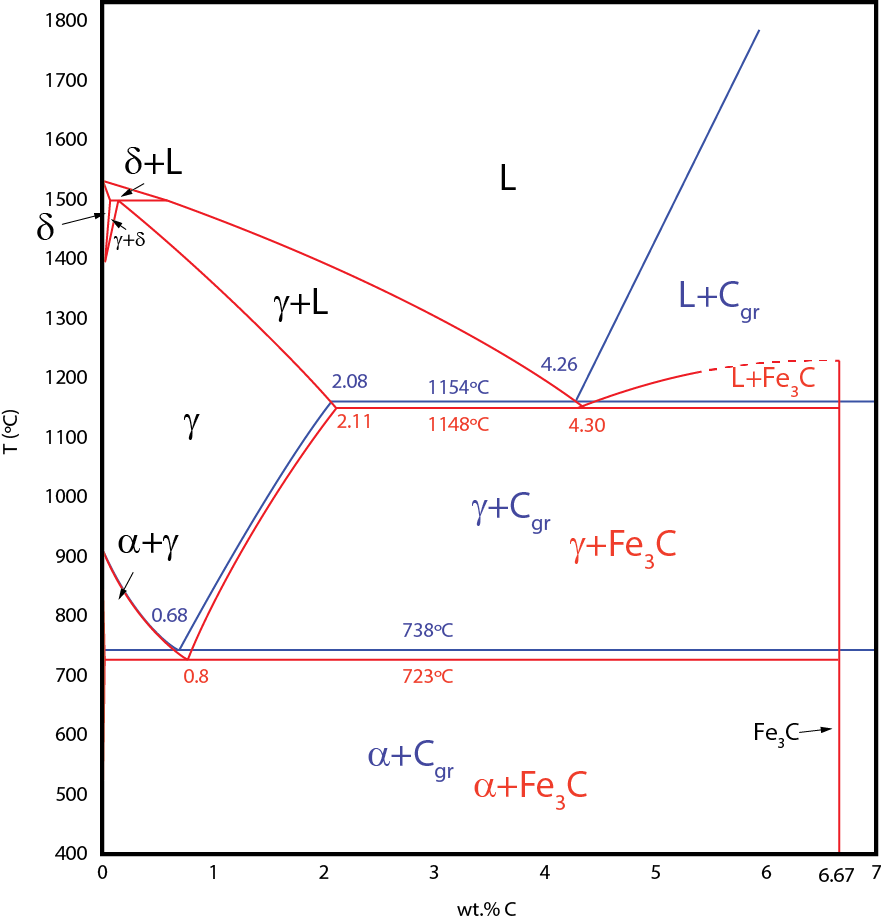

Initially this specimen was a white iron, but after annealing it transformed into a more tough and ductile material, which explains the term "malleable". However, this term is misleading since the applied heat treatment is not intended for producing a material that is ready to be plastically deformed. The malleabilization treatment consists of two steps: (i) graphitization, typically at 900-920 °C for 60 h, in order to decompose cementite into graphite and austenite; and (ii) cooling to transform austenite into the desired constituent (ferrite, ferrite-pearlite, pearlite, etc.).

In the micrographs, irregular graphite nodules are visible together with ferrite grains and pearlitic colonies. Some MnS inclusions are also present. The cooling rate applied to this specimen produced a mixed matrix, where the ferrite grains surround the graphite nodules, whereas the pearlitic colonies are further away. This layout is known as bullseye microstructure.

Fe-C diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.