Ti6Al4V-D

Duplex or bimodal

Composition: Ti-6%Al-4%V.

Processing: Annealing (970ºC - 10 min), Air cooling.

Etching: 30-120s immersion in mixture of acids (HCl+HF+HNO3).

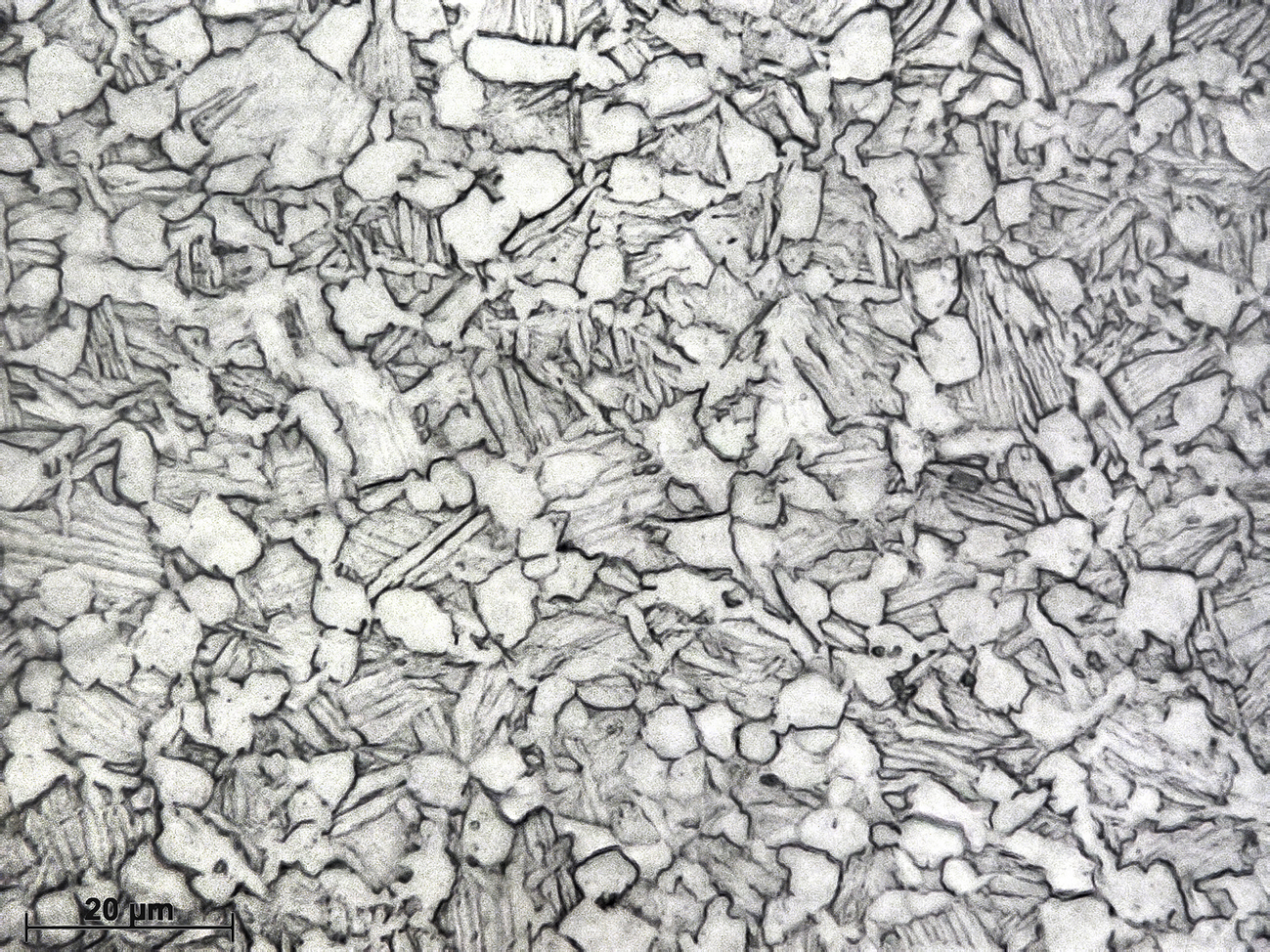

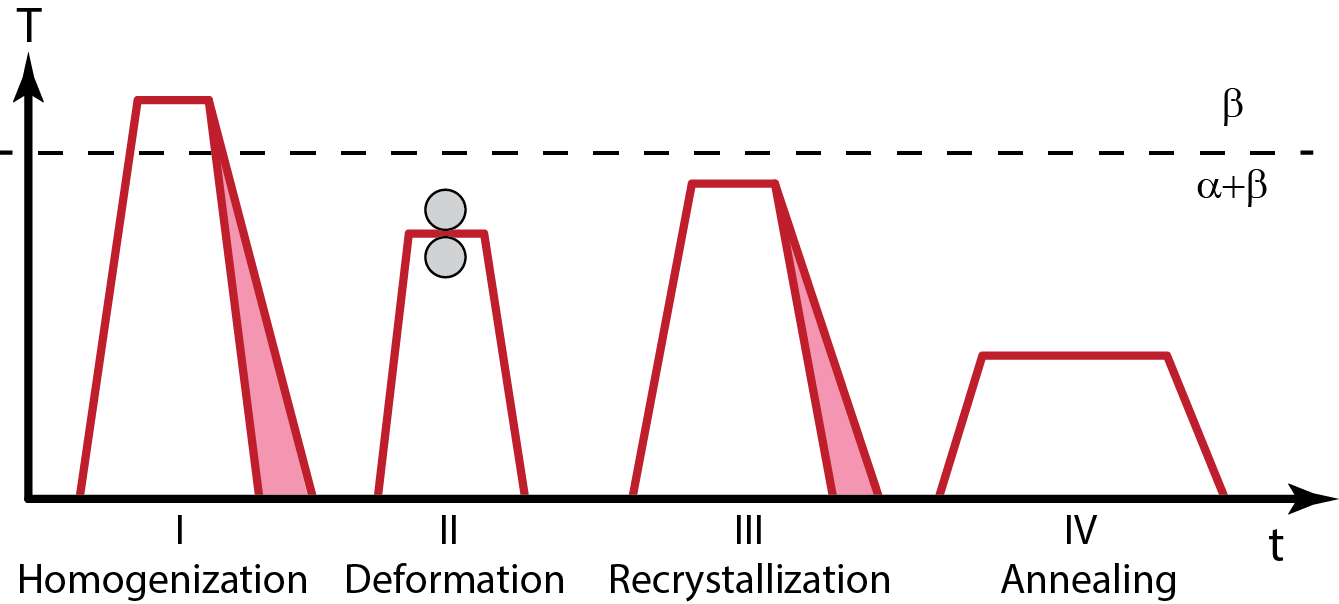

Micrographs show a duplex or biomodal structure consisting of equiaxial grains of primary α phase (αp) and grains with a lamellar aggregate (α + β). The term duplex derives from the dual morphology of the α phase. The cooling rate from the β field during Stage I determines the size of the initial α lamellae, which in turn define the size of the equiaxial grains that are formed after Stage III. So, when the cooling rate during Stage I is slow, wide lamellae are formed which later evolved into relatively large equiaxial αp grains.

The recrystallization temperature and the cooling rate during Stage III determine the volume fraction of αp and the width of the α lamellae that are formed within β grains. The size and volume fraction of αp grains influence the β grain size during recrystallization. This is the most determining factor for the mechanical properties of duplex microstructures (smaller grains are usually preferred). In comparison to Widmanstätten structures, duplex alloys show higher yield strength, ductility and low cycle fatigue performance due mostly to the small size of β grains and the α colonies in them. The smaller the colony size the shorter the slip length of dislocations, thus increasing the resistance to crack propagation.

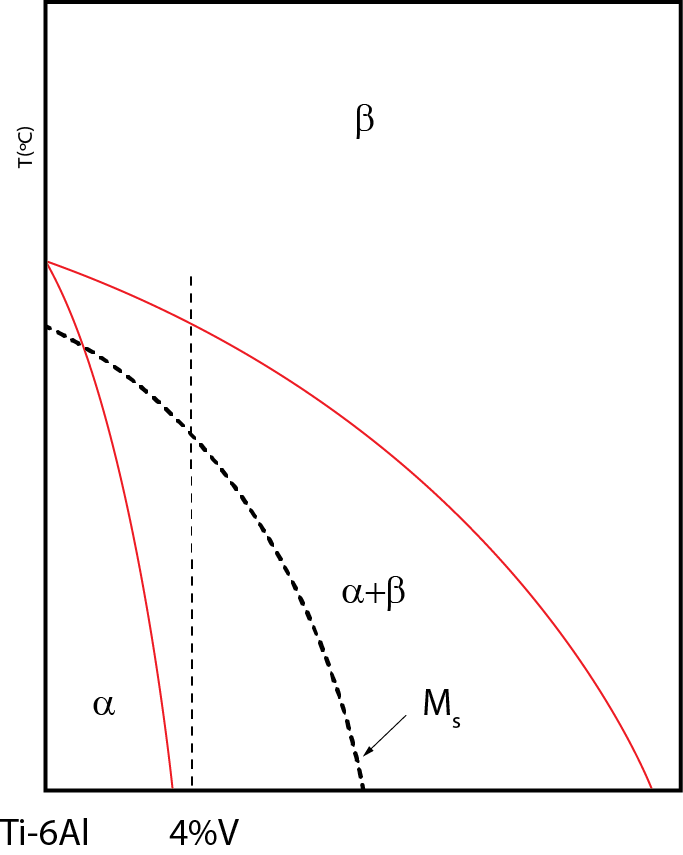

Ti6Al-V diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.