AC3

F513 (martensite and "troostite")

Composition: 0.70-0.80 C; 0.25-0.50 Mn; <0.25 Si; <0.03 P; <0.03 S.

Processing: Annealing (950ºC - 20 min) and Water quenching.

Etching: 15-30s immersion in 2% nital.

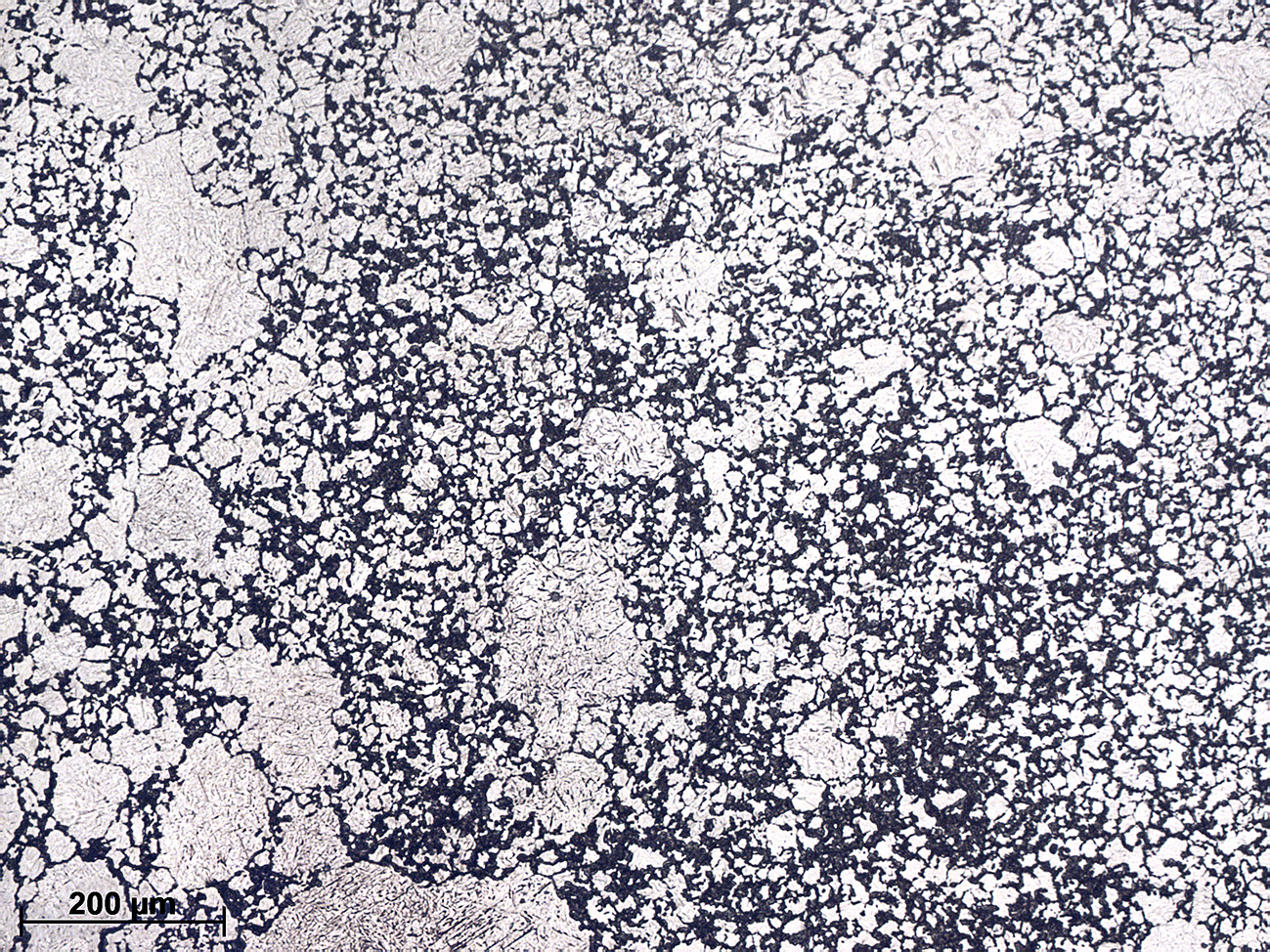

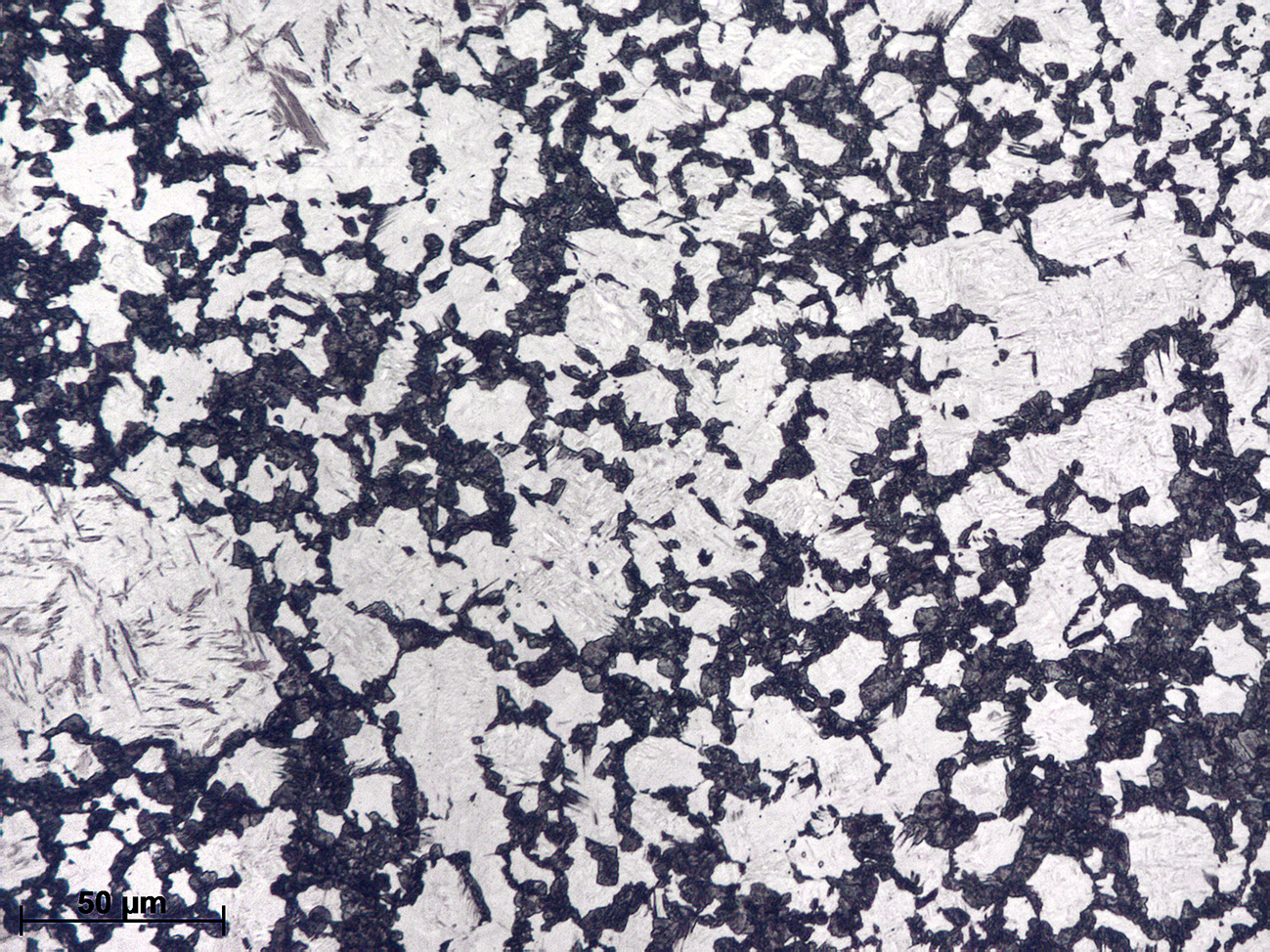

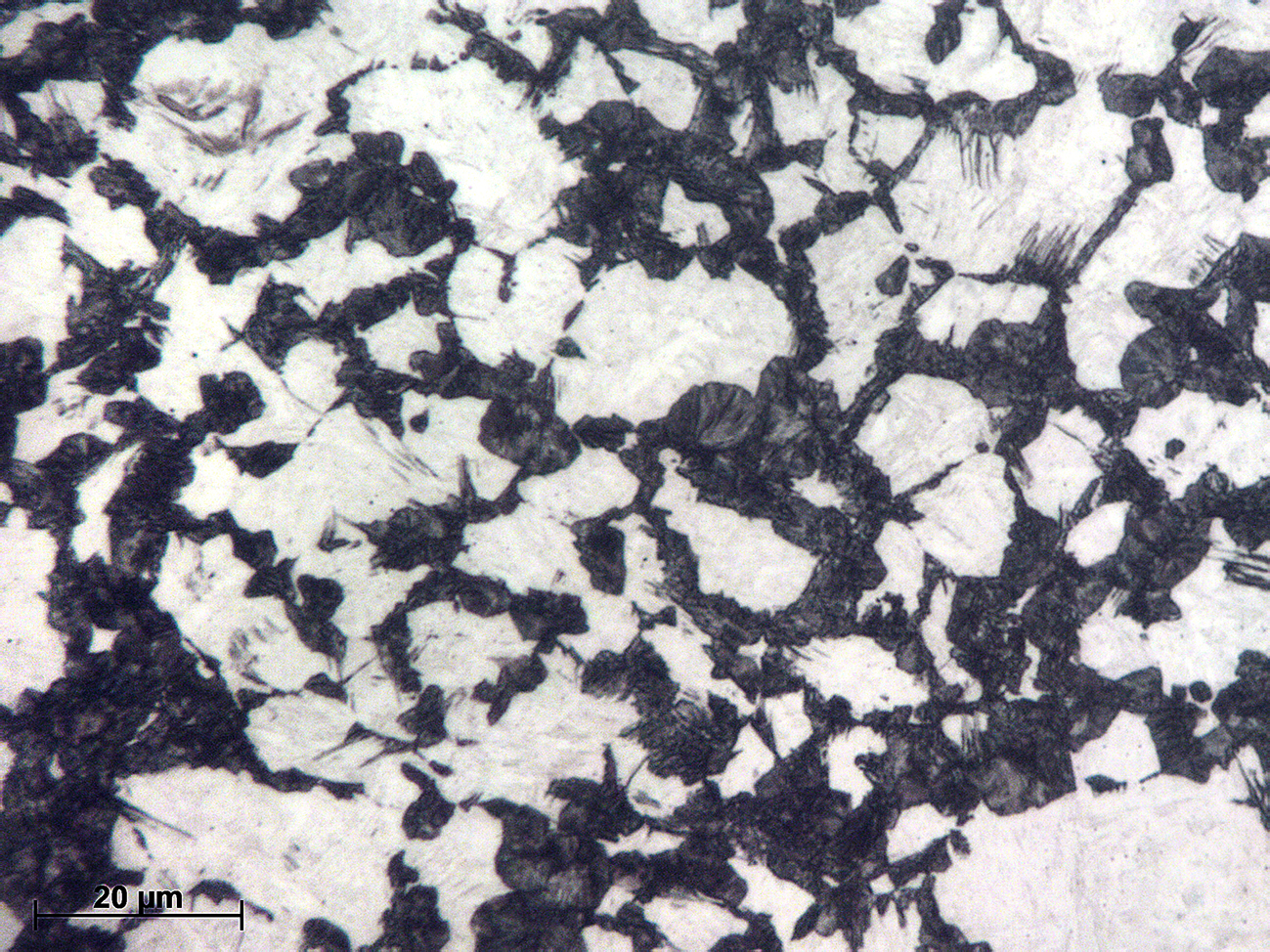

The composition of this material corresponds to a carbon steel for tools such as drills and chisels. If carried out propertly, this steel should show martensite and some retained austenite after quenching, however, in this case the annealing temperature was excessively high. Therefore, during water quenching the critical quenching rate is not achieved and there is precipitation of fine pearlite with a nodular morphology and located at the grain boundaries of the original austenite. This constituent, consisting of very fine lamellae of ferrite and cementite (100 nm width) cannot be resolved by optical microscopy and it was named Troostite after Louis-Joseph Troost. This term is now obsolete since troostite is in reality fine pearlite. This nodular morphology of pearlite can also be obtained by isothermal treatment at temperatures between 500 and 600ºC.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.