5086-SE

Al-Mg alloy, solution heat treated, quenched and overaged

Composition: 4.1 Mg; 0.45 Mn; 0.10 Cr; 0.34 Fe; 0.24 Si; 0.03 Cu, bal. Al.

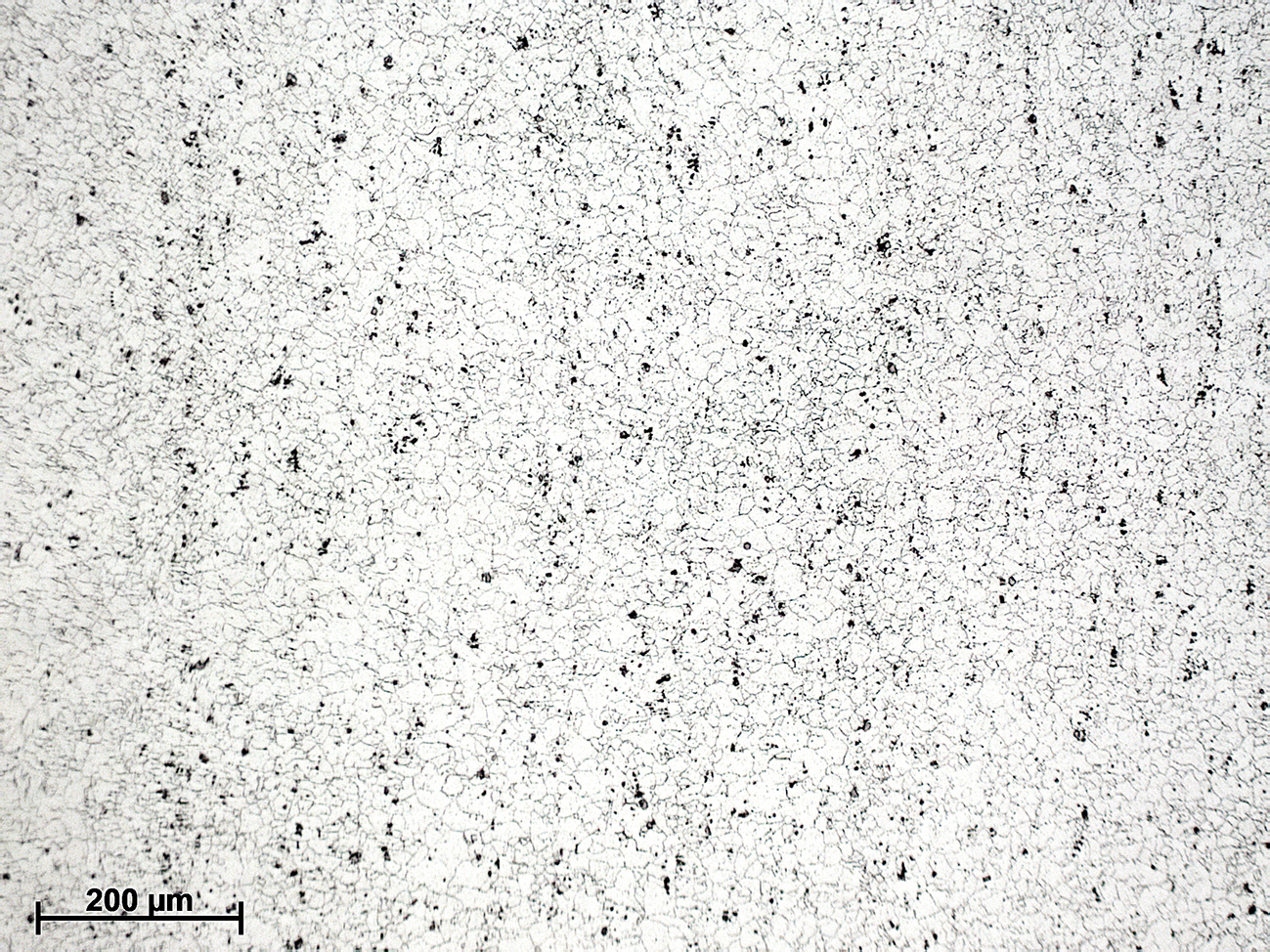

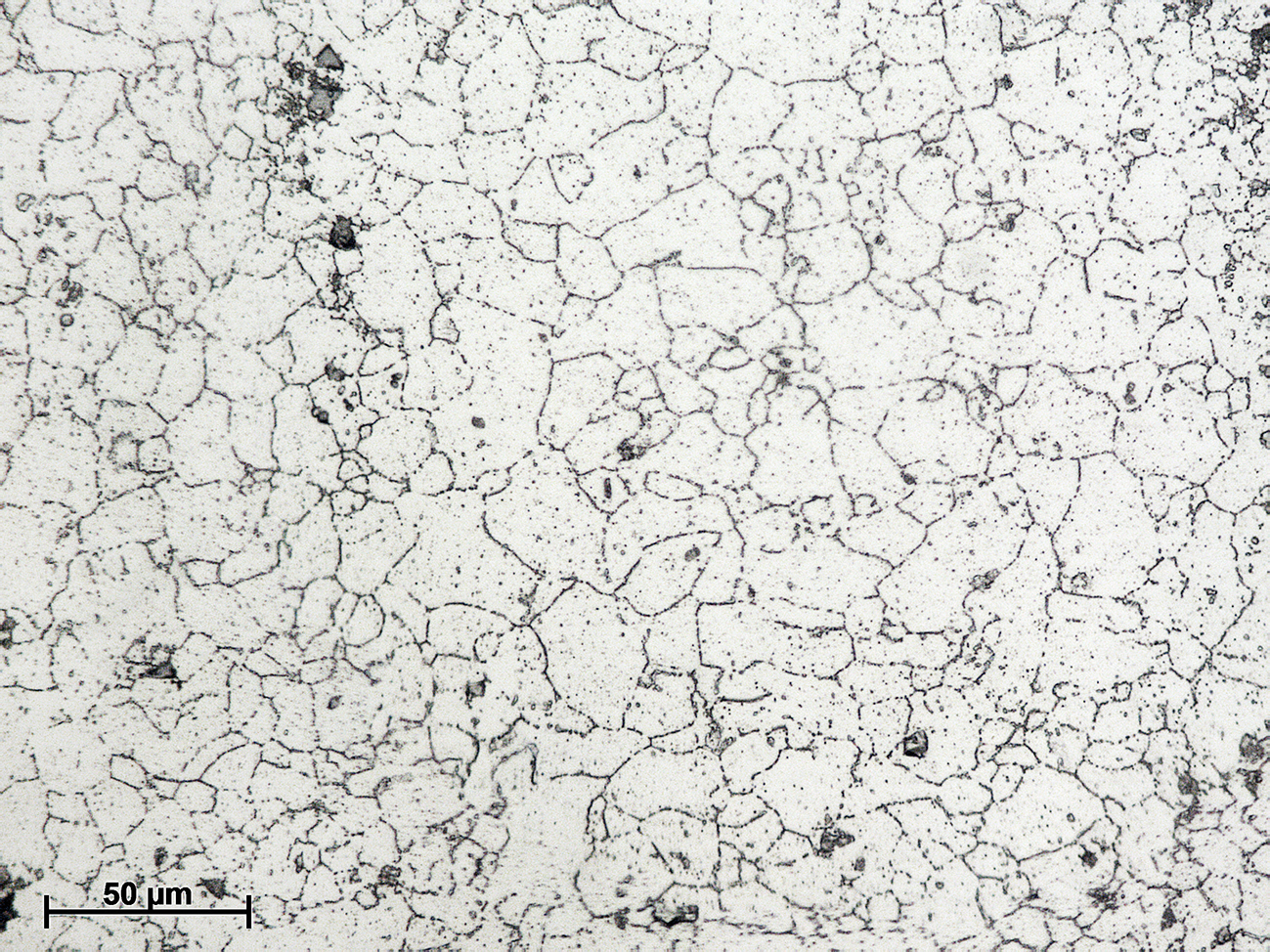

Processing: Forging, rolling, annealing (430ºC - 8 h), water quenching and overaging (150 ºC - 11 days).

Etching: 30-120 s immersion in mixture of acids (HCl+HF+HNO3).

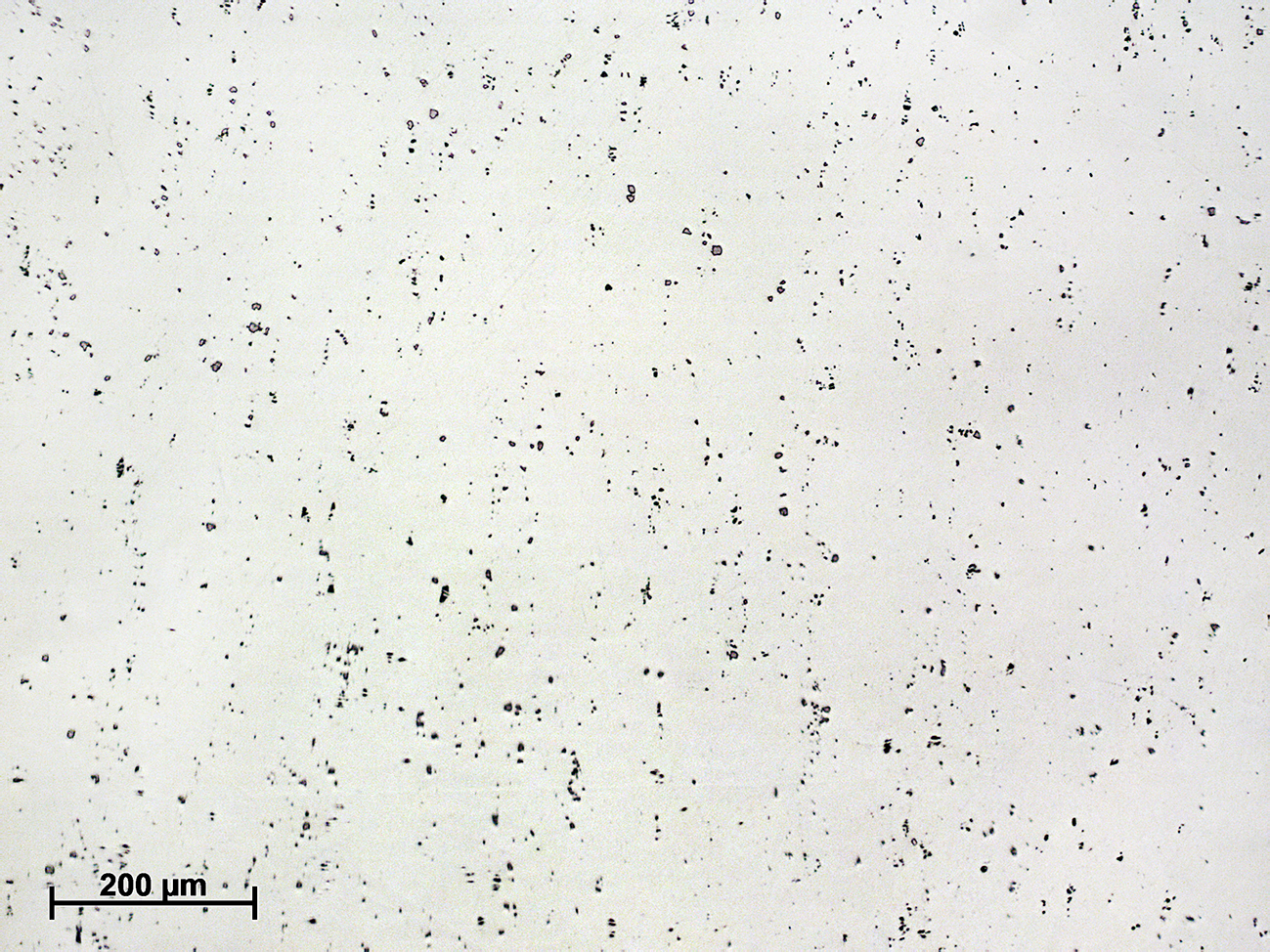

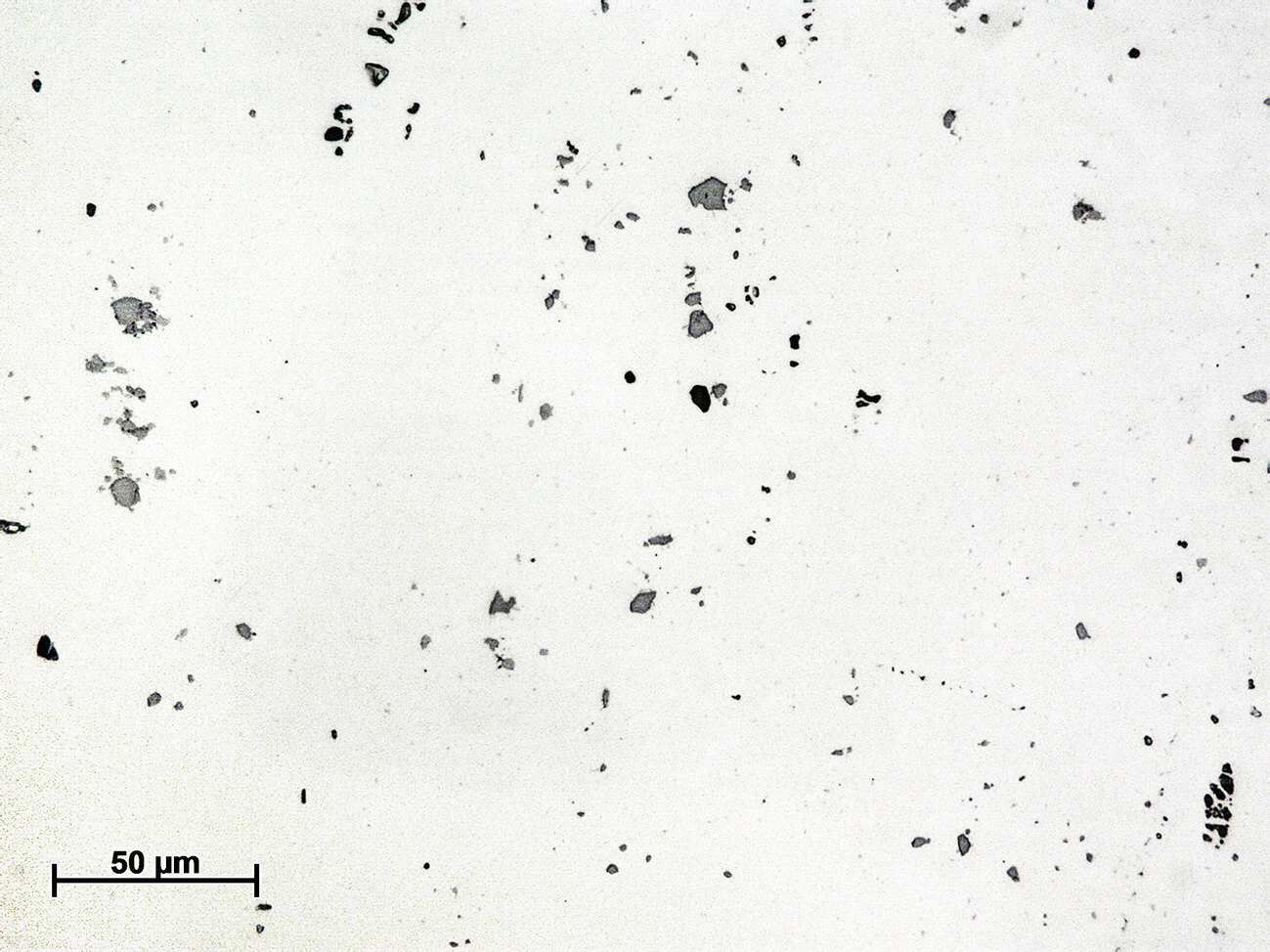

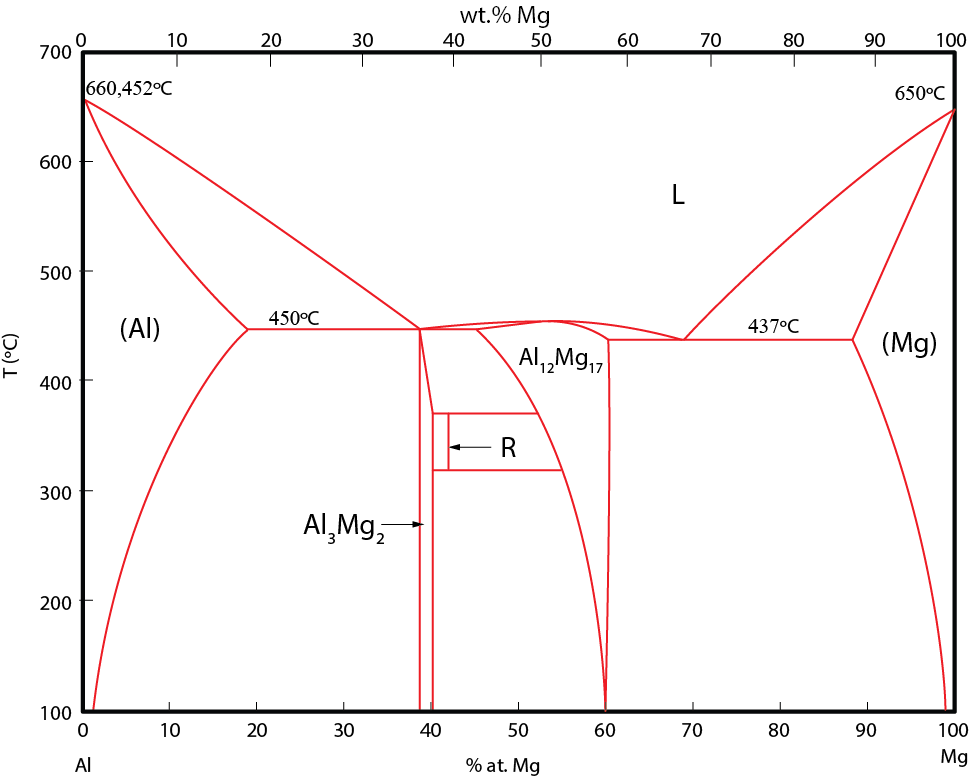

Similarly to the 5086-ST specimen, the microstructure consists of α-Al grains, intermetallic compounds Al3Fe (gray) and Mg2Si (dark), and dispersoids (Al6(Cr,Mn), Al18Mg3Cr2). Due to the overaging treatment, and according to the phase diagram, there is precipitation of Al3Mg2. This occurs at the grain boundaries, which are revealed after etching. The grain boundary precipitation of this phase should be avoided, since it renders the alloy more susceptible to corrosion phenomena, especially in those cases when the amount of Mg is above 3.5%.

Al-Mg diagram

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.