Nanomaterials Preparation and Encapsulation by Supercritical Fluid Extraction of Emulsions (SFEE)

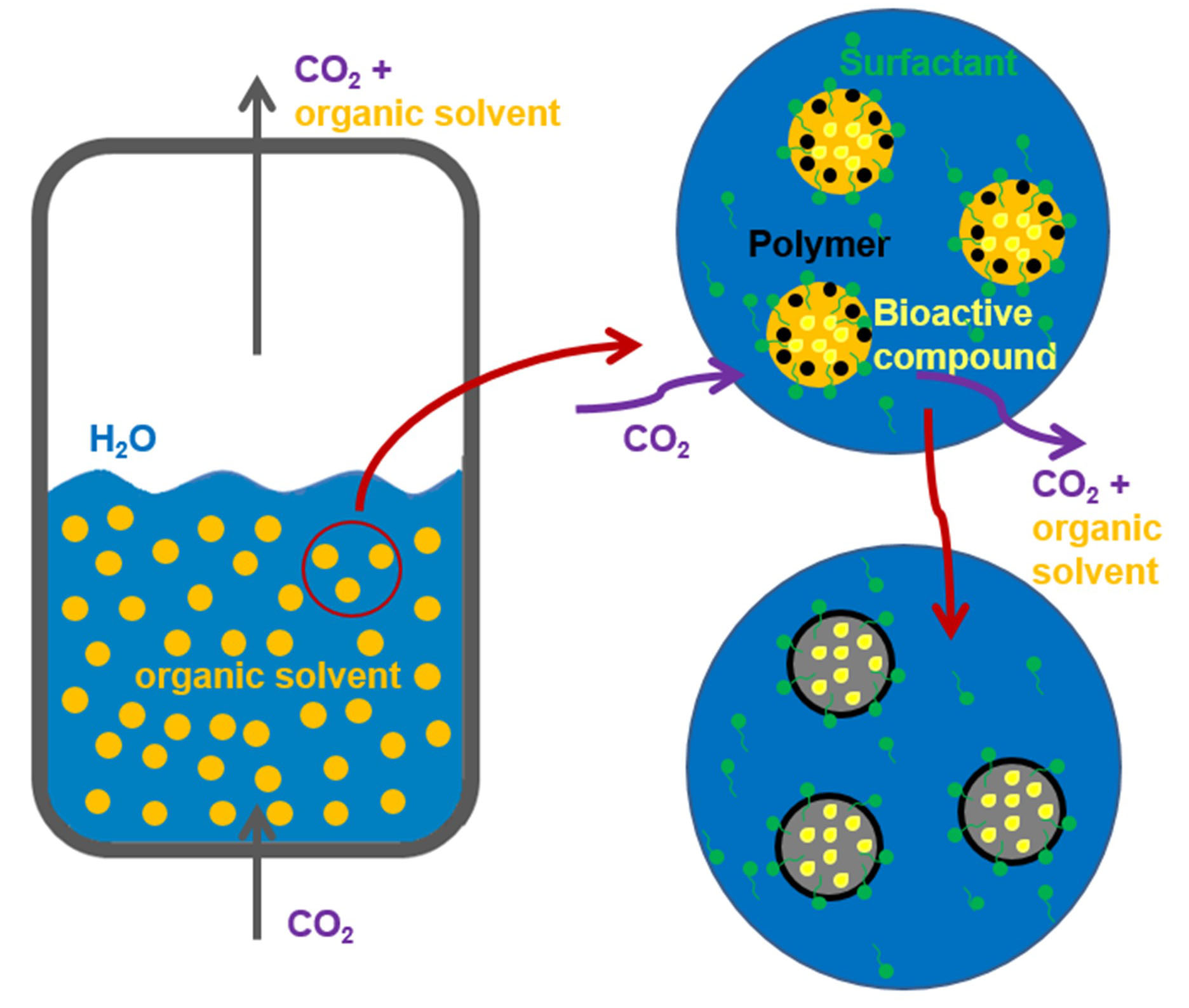

In Supercritical Fluid Extraction of Emulsions (SFEE), supercritical CO2 is used to rapidly extract the organic phase of an emulsion in water (O/W). The compound to be micronized is previously dissolved in this O phase. When the solvent is removed, the compound precipitates in small particles that remain suspended in the water. They are stabilized and dispersed by a food approved surfactant. A variation of the method is used to generate composites. Both the active compound, and the support or coating, are dissolved in the organic phase; so, when this is removed, homogeneous aggregates or even true core shell capsules are generated. Figure 1 shows a scheme of the process. If the active compound is soluble in water, double emulsions (W/O/W) are used.

Figure 1. Scheme of the SFEE procedure.

The technology can be applied to the micronization and encapsulation at micro and nano scale of sensitive compounds, such as pharmaceuticals (for their protection and/or controlled release), nutraceuticals, bioactives and probiotics (for their incorporation into functional foods), cosmetics, pigments, explosives, semiconductor precursors, etc.

Advantages:

- Fine control of particle size as well as shape. The particles have spherical morphology and there is no aggregation.

- High encapsulation efficiency (>80%) and active compound/particle ratio (>30%)

- Moderate use of pressure (<80 bar), low temperature (<40ºC); so that operating costs could be easily amortized by the added value of the product.

- The process can be carried out continuously, with recirculation of both the organic phase and the CO2.

- Scaling up to large productions is easy since conventional extraction technology in packed columns can be applied.

Experience and Capabilities:

The technology is under research, although it is proven in several pharmaceutical and food products. We have achieved the nanoencapsulation of solid and liquid compounds at pilot scale in continuous operation. It is also possible to finely micronized pure substances and polymers used as supports in biomedical applications and catalysis.

We can carry out proof-of-concept procedures on all kinds of materials. We also have the facilities to evaluate the degree of encapsulation, the morphology of the particles and to determine the physical-chemical characterization of the prepared materials. For drugs, we can do in vitro tests (dissolution and release) as well as stability tests. We can model the process to make larger scale designs.

Examples:

Figure 2 shows the a) optical microscope image of the emulsion processed by SFEE to obtain composites of Axtashantine in Ethyl celullose. Image (b) shows the SEM and c) the TEM images of the obtained particles, while image d) shows the narrow particle size distribution around a mean size of 360 nm.