Micronization by Supercritical AntiSolvent (SAS)

The precipitation by Supercritical Antisolvent (SAS) technique can be applied to the micronization of drugs, pigments, polymers, explosives, inorganic precursors,… These compounds are generally large or polar molecules that exhibit low solubility in supercritical CO2, but they are very soluble in polar organic solvents. The technique is based on the antisolvent effect that supercritical CO2 has after being mixed with a solution of the compound in an organic solvent. When CO2 contacts the organic solution with the solute to be micronized and is dissolved in the solvent, the liquid experiences a volumetric expansion and becomes a bad solvent of the solute, which precipitates as micro and nanoparticles. The morphology, crystal structure and particle size can be controlled by modifying the temperature and pressure of the process, the solvent, etc… Solvent-free particles exhibiting a narrow particle size distribution are obtained.

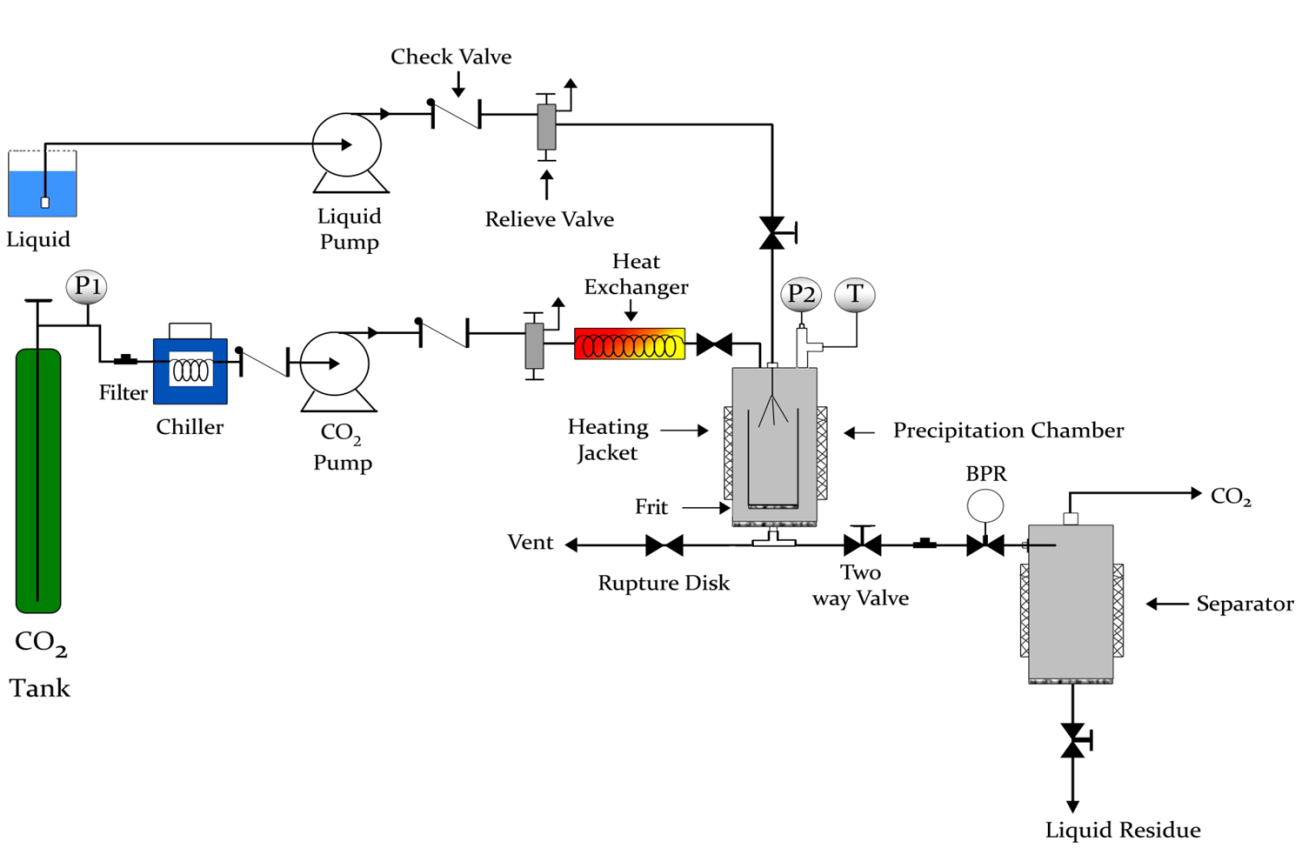

A scheme of the experimental device used is shown in Figure 1. A high-pressure pump drives supercritical CO2 at the working temperature and pressure towards the precipitation chamber which is under the same conditions at a constant flow. The liquid solution formed by the solid and the organic solvent is also introduced at constant flow into the precipitation chamber through a nozzle. Current precipitation temperatures vary from 35 to 70 ºC, at pressures ranging from 8 to 20 MPa. When the supercritical fluid dissolves in the organic solvent, the solution becomes supersaturated and the solute precipitation starts. Pressure is controlled by a back pressure regulator at the exit of the precipitation chamber. The micronized solid is collected in the precipitation chamber whilst the CO2 + organic solvent mixture is separated in a cyclone separator. The precipitate is washed with supercritical CO2 to remove any solvent residue.

The micronized materials are characterized by X ray diffraction (low and wide angle), thermal analysis (TGA, DTA), FTIR and UV-vis spectroscopy, electron microscopy (SEM and TEM), composition analysis by EDX and microanalysis,…. Dissolution rate assays of the drugs are also performed.

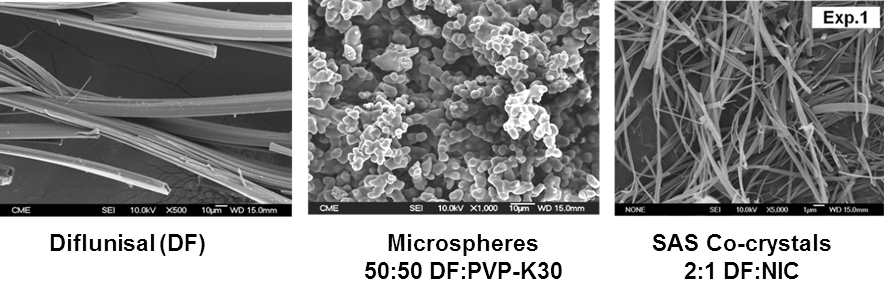

Using this technique, we have precipitated different drugs such as diflunisal (DF- an analgesic and anti-inflammatory API), and different drug formulations such as those formed by DF and the polymer PVP, and the cocrystals formed by DF and nicotinamide (NIC- water soluble compound member of the vitamin B family).

Figure 2 shows SEM images of these materials. In every case, due to the change of properties in the formulation and to the morphology and size control achieved using the SAS process, all the composites prepared show an improvement of the dissolution rate in comparison to the pure drugs.

In comparison, traditional micronization techniques such as grinding, crystalization, “spray-drying” or “freeze drying” present many limitations such as the poor control of particle size and, sometimes, the high temperature required to remove the solvent. On the contrary, precipitation by SAS leads to solvent-free materials and allows controlling the morphology, size and polymorphic phase of the precipitated material.