TECHNOLOGY FOR USED FRYING OILS TREATMENT

|

Description |

Frying oils from the hotel and catering sector and industrial kitchens, currently represent a major environmental problem. Only a small percentage of these oils are collected as controlled release and is used as a raw material in the manufacture of soaps, however most of these residual oils represent an added burden for the wastewater of these industries, with the consequent environmental damage.

The developed process allows the use of frying oils used as raw material for industrial biotransformations to obtain value-added products, such as surfactants, additives for cosmetics, lubricants, food additives or hydraulic fluids. With this technology, it is intended to reduce the deterioration of the existing environment in the sector due to the discharges of these residual oils.

|

How does it work |

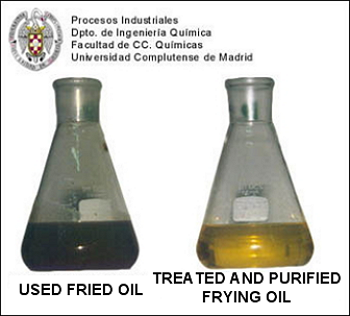

Used frying oil, before and after be subjected to treatment and purification described herein.

Used frying oils, originated from hotel and catering sectors and industrial kitchens, are made suitable for use as raw material in chemical transformation processes to obtain a range of products with applications in the cosmetic industry, pharmaceutical, lubricants, food additives, hydraulic fluids, surfactants or emulsifiers. In these hydrolysis processes fatty acids are obtained and glycerin as a subproduct.

So, for the whole process to be profitable from an economic point of view, they have been developed processes for obtaining products based on glycerin, described above. The procedure goes through a preconditioned of the fried oils used by decantation, filtration, degumming, neutralization, decolorization and deodorization operations, as well as a selection of products of interest and an identification of the reaction system, both the chemical species involved and the appropriate catalyst systems.

The research group has developed an analytical method to quantify and identify the species present in the reaction medium, for which techniques of mass spectrometry and gas chromatography are used.

|

Advantages |

It is a clean and viable process from the point of view of the environment preservation:

- It avoids the use of strong mineral acids, conventionally used for these systems.

- The possible aqueous effluents have a neutral pH and they require a minimal treatment.

- It offers the possibility of working in smooth conditions of operation.

- No corrosion problems occur in either reactors or auxiliary equipment.

This process allows to obtain high conversions and selectivities:

- No side products are obtained.

- Conversions are above 90% for short periods of reaction.

The process offers the possibility of scaling: given the characteristics of these processes, the scaling can be carried out with certain guarantees for industrial implementation.

|

Where has it been developed |

The process of treatment and utilization of used frying oils, both for the use as liquid fuels and for the production of fine chemicals of wide industrial interest, it has been developed in the Chemical and Biochemical Processes Laboratories, integrated in the Chemical Engineering Department of the Chemical Science Faculty at the Complutense University of Madrid.

The developed technology allows the use of a high volume raw material, with a residual origin and highly polluting, for reuse. For being an application capable of processing these waste materials, the procedure constitutes a clean technology.

The research team, who developed this process, has extensive scientific expertise (scientific publications) and technical expertise (patents and agreements with industries) in the use of vegetable oils in non-food uses.

|

And also |

The technological contribution of the Research Group is as follows:

- Pilot Plant Scale: We have both the process engineering and the details for the treatment process of frying oils to scale Pilot Plant (Reactor 0.70 m3).

- Scale Industrial Plant: It has been achieved the engineering process for the treatment of frying oils. We have enough experience to design the process on an industrial scale, 40,000 MT/year.

The process described herein, it is aimed primarily to institutions and local and regional administrations. We can train operators of pilot plants and provide technical assistance if required. We can also perform technical and economic feasibility studies for a product or product ranges.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

Mercedes Martínez Rodríguez: mmr1@quim.ucm.es

Department: Chemical Engineering

Faculty: Chemical Sciences