BIOHYDROMETALLURGY APPLIED TO METALS RECOVERY AND TO SOILS AND EFFLUENTS DECONTAMINATION

|

Description |

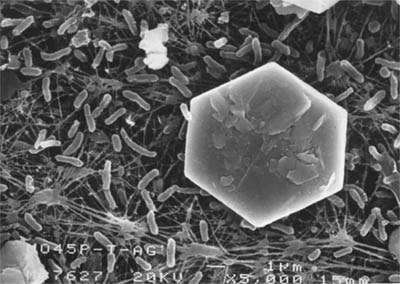

Mesophilic bacteria Acidithiobacillus surrounding a molybdenite crystal

Biohydrometallurgy is a technology at the interface between biotechnology and materials that attempts to solve different aspects related with metal extraction (bioleaching), liquid effluents decontamination (biosorption and bioaccumulation), soils decontamination (bioremediation) and production, migration, control and abatement of acidic waters (acid mine drainages). In all these processes with either the direct or indirect participation of living organisms.

|

How does it work |

Bioleaching columns: treatment of uranium ores at semi-pilot scale.

The fundamentals of the different fields within biohydrometallurgy can be summarized as follows:

Bioleaching, also known as bacterial leaching, consists in the chemical attack of different natural raw materials, industrial residues or recycled products, through the direct or indirect participation of bacteria. Although these are mostly mesophiles, e.g. A. ferrooxidans, thermophilic microorganisms with growing temperatures up to 80 ºC are increasingly being taken into account.

Bioaccumulation and biosorption are two techniques that use different kinds of biomass, either alive or dead, respectively, for the decontamination of liquid effluents loaded with heavy metals. They are complementary techniques to other more commonly used such as the chemical precipitation of hydroxides and other metallic salts; however, those techniques, unlike the conventional ones, can be applied and be effective to treat effluents with very low metal concentrations. They are basically based on ion exchange phenomena between the biomass surface involved and the metal ions present in the contaminated aqueous solution.

Bioremediation involves a group of techniques that can achieve simultaneously both the degradation and decontamination of several compounds retained in urban or industrial soils by means of different microorganisms (fungi, yeasts and bacteria). These methods are especially useful for the treatment of soils contaminated with wastes highly refractory to the conventional clean-up methods.

Finally, acid mine drainage is a growing environmental threat due to the abandonment of hazardous solid wastes containing soluble sulphur. As a result of the interaction between an oxidizing environment and these products, acid drainages (pH 2-3), loaded with sulphuric acid and with a high capacity to mobilize heavy metals, are generated. The presence of bioleaching microorganisms in natural environments can speed up sulphur oxidation processes under normal atmospheric conditions.

|

Advantages |

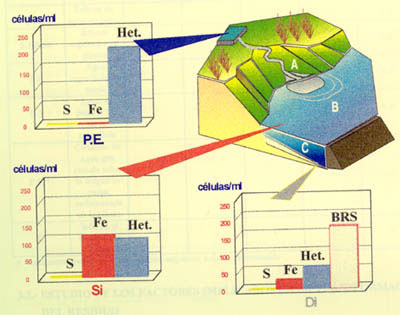

Mine acid drainages: microbiological characterization of a tailings dam.

While some of these technologies are fully developed others are not yet. In some cases these processes are already competitive against abiotic conventional processes but in other cases they are under implementation and development to be further applied at industrial scale. For instance, bioleaching is being applied at industrial scale for the treatment of copper, uranium and gold ores, and still is competitive against other methods.

On the contrary, biosorption has not been yet implemented to industrial scale though the knowledge achieved seems enough as to scale-up the process in the short term. In general, the main advantage of all these methods is that they are much less polluting than conventional technologies since often they are mediated by living microorganisms that maintain the system under acceptable environmental conditions.

|

Where has it been developed |

This line of research and applied technology has been developed in the Departamento de Ciencia de Materiales e Ingeniería Metalúrgica at the Facultad de Ciencias Químicas of the Universidad Complutense de Madrid. The Biohydrometallurgy Group has more than 30 years’ experience in this research field.

In the bioleaching area, the group has signed major applied research contracts, among others with national (ENUSA) and international (BHP Copper) mining companies. In this field, the group has wide experience in solving the main drawback of this technique: its slow kinetics. For that, different solutions have been adopted, such as: the use of metal ions in solution able to catalyze the process, the isolation and use of thermophilic microorganisms and new ones isolated for first time by this research group.

Regarding the studies on the generation of acid drainages, the group worked with Almagrera, SA, a Spanish company which owned an important mine bearing complex polimetallic sulphides, located on the Iberian pyritic belt in the southeast of Spain. The aim of this project was to determine what caused the production of acidic effluents in their tailings dams.

On the other hand, the group has extensive experience in the decontamination of liquid effluents by biosorption not only with monometallic systems but also for the treatment of multimetallic systems, which is a feature hardly explored in the scientific literature. Our studies in this field have also included the modelling of these systems using different types of software designed for such purpose. At present, the Biohydrometallurgy group is involved in an international Project, “BIOMETAL Demonstration Plant for the Biological Rehabilitation of Metal Bearing-Wastewaters (BIOMETAL DEMO)”, funded by the European Union, that has as the main objective to design 3 decontamination pilot plants to be operated with different biomasses by the industrial companies participating in the consortium.

Additionally, the research group has carried out investigations on the bioremediation of soils contaminated with products derived from petroleum with or without transformation. REPSOL-YPF and ENUSA showed a certain interest in these works.

Finally, the group is now involved in another national Project, MAT2014-59222-R, granted by the Secretary of State for Research, Development and Innovation of the Ministry of Economy and Competitiveness (MINECO), aimed to design bioprocesses to synthesize iron solid compounds by means of different kinds of microorganisms, both Fe-reducing and Fe-oxidizing ones, that could be used for several environmental purposes, but especially in the remediation and treatment of industrial effluents loaded with heavy metals.

|

And also |

The UCM Biohydrometallurgy research group has the means to tackle projects dealing with any issue related to the technologies previously mentioned both at laboratory and semi-pilot scale. On the other hand, the group’s staff has taught various courses for the dissemination of these technologies and has the capacity to train anyone who may be interested in the subject.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

Antonio Ballester Pérez: ambape@quim.ucm.es

Department: Materials and Metallurgical Engineering

Faculty: Chemistry Sciences