THERMOMECHANICAL TREATMENTS FOR OBTAINING HIGH MECHANICAL PERFORMANCE STEELS WITH HIGH CHROMIUM AND CARBON CONTENTS

|

Description |

Thermomechanical process to achieve a high mechanical performance of strength, hardness, hardness and wear resistance with high chromium martensitic (Cr> 12% by mass) and carbon (C> 1.5% by mass) stainless steels and good Tensile strength Corrosion.

Their destination is the manufacture of white weapons, generally covered, sports equipment, cold cutting tools and mechanical parts of very high performance.

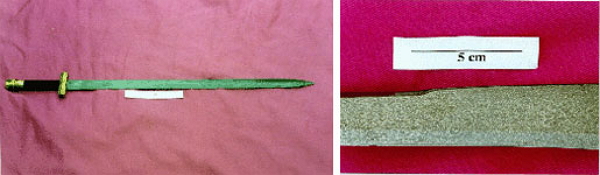

Sword forged with high performance steel and detail of the same in which the martensitic structure is appreciated.

|

How does it work |

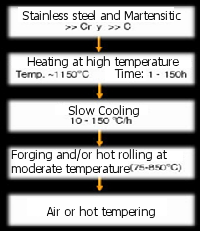

Scheme of the forging process.

This thermochemical treatment aims to increase the wear and tear resistance without loss of toughness; Increasing, by annealing at very high temperatures (at about 1150 ° C) and different time intervals, the size of the proeutectoid chromium carbides and after forging and / or hot rolling at low temperatures (750-850 ° C) of large steels Chromium content (> 12% by mass) and Carbon (1.5-2.1% by mass).

The cooling to the air or in oil obtains the appearance of a martensitic structure and carbides of Chromium distributed in her forming bands (strings). The hardness achieved with this temperature exceeds the hardness of 73 HRc.

|

Advantages |

The thermomechanical treatment designed to give a mechanical performance to martensitic stainless steels which in some cases doubles these compared to the best alloyed steels and other metal alloys suitable for cold work and temperatures below 450 ° C.

In melee weapons, cutlery and sporting equipment after polishing and etching with strongly oxidizing reagents, it has a very remarkable surface beauty only surpassed by the Damascus steels.

|

Where has it been developed |

This technology has been developed by the Group of Mechanical Technology and Archaeometallurgy. Department of Materials Science and Metallurgical Engineering. Faculty of Chemical Sciences.This Research Group has great experience and international prestige in archeometallurgy, nuclear technology and conventional mechanics.

Studies on archaeological metal pieces are being highly sought after by today's industry. Organisms such as the Army Museum, the Provincial Council of Cordoba, the City Council of Obejo (Córdoba), and the Commission of Professional Archaeologists in Madrid request our services to study and rescue valuable archaeological pieces such as the Tizona sword or Mehemet Ali's cutlass, As well as for the dating and study of the deterioration and origin of the most varied metallic objects.

In the field of steel design for various applications we have a proven experience. Thus, we have rescued old technologies such as Damascus steel presented here or the Toledo Steel, not forgetting the current steel between which we have designed a type that is possibly the most resistant and hard of those that exist today.

|

And also |

From the Metallurgical Industry to the Electronic Industry, passing through Aerospace, we have researched, advised and exchanged knowledge and technologies for more than a decade.

In the nuclear industry our expertise in the field of nuclear fuels has enabled us to investigate and advise institutions such as the Central Bureau for Nuclear Measurements (Geel-Belgium), Transurane Institute (Karlsruhe-Germany), Institut for Avanced Materials (Ispra - Italy-).

Within the field of advanced materials we are working on the study of corrosion, metallography, mechanical design, destructive and non-destructive mechanical tests with the Clausthal Universität and Fraunhofer Institut für Chemische Technologie (Pfinztal-Germany).

The Archaeometallurgy group has great experience in adapting the technology to the specific problems of the customer and is available, due to its long experience, for training in the use of the technology in question, as well as to offer technical assistance after purchase.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researchers |

José Antonio Criado: antoniocriado@quim.ucm.es

Department: Materials Science and Metallurgical Engineering

Faculty: Chemical Sciences