SOLAR CONCENTRATION PLANTS: MATERIALS, COATINGS AND STORAGE FLUIDS-NEW DESIGNS

|

Description |

The evolution that these plants are suffering, in order to increase the operating temperature to enhance the energy efficiency and to install thermal storage tanks to operate in continuous and to become competent against other technologies, is causing the need to:

- Modify the materials, which used until now.

- Use coatings with a suitable optics for maximum solar absorption.

- Utilize thermal storage fluids, to operate during the night or on cloudy days.

|

How does it work |

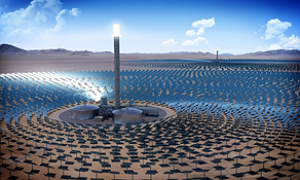

Concentrating solar power (CSP) uses mirrors or lenses to concentrate sunlight on a small surface. Electric power is produced when concentrated sunlight heats a fluid, which in turn heats up the water vapor that drives a turbine and a generator transforms that energy into electricity. The two best known technologies are:

-Central tower plants: where a combination of heliostats (flat mirrors) concentrate the heat of the sunlight at a point (receiver at the top of a tower). The fluid circulating through the receiver absorbs solar radiation.

Example of cilindric-parabolical central

-Parabolic trough plants: where rows of reflectors with parabolic section focus the sunlight on the collecting tubes through which the heat transfer fluid circulates.

To form a competent technology is necessary to install a system of storage of the heat obtained during sun hours, for this, the field of molten salts is currently being opened as a storage fluid and as a heat transfer fluid in order to replace the present heat transfer fluid (thermal oil) that reaches very limited maximum temperatures and has high toxicity.

|

Advantages |

- Increases energy efficiency.

- Operates in continuous.

- Replaces the current thermal oil used as a heat transfer fluid (because it is toxic).

- Increases the level of solar absorption in the receptors.

|

Where has it been developed |

The Research Group of Surfaces Engineering and Nanostructured Materials, ISMN (Nº 910627), of the Department of Materials Science and Metallurgical Engineering of the Faculty of Chemical Sciences, aware of this need, has thrown itself into developing new formulations of molten salts which improving the properties of Solar Salt, currently employed in the few plants that use this technology.

In turn, given the experience of more than 25 years in the investigation of corrosion phenomena at high temperature in the presence of molten salts, has also produced new coatings that are able to control the corrosive phenomena that this type of fluids causes.

|

And also |

The services that can be provided by the Surface Engineering and Nanostructured Materials Group in this area are as follows:

- Adapt the technology to the specific customer problems.

- Carry out technical feasibility studies for a particular application.

- Possibilities of technical assistance during the working process.

- Training for the use of the technology in question.

- Monitoring corrosion at high temperature.

- Life-cycle assessment LCA.

- Analysis of failures in service.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

Francisco Javier Pérez Trujillo: fjperez@ucm.es

Department: Material Sciences and Metallurgic Engineering

Faculty: Chemical Sciences