METHODOLOGY FOR FLOCCULATION CONTROL

|

Description |

Flocculation-deflocculation-reflocculation process.

The traditional methodologies, based on the measurement of the surface charge of the particle are only appropriate to study the aggregation process when it implies the modification of these properties, but not when the flocculation is carried out by other mechanisms as bridging with neutral polymers, for example. However, the developed methodology is appropriate to study every flocculation process, independently of the aggregation mechanism or the suspension nature.

Most of the optical techniques used to studying the flocculation process requires the previous manipulation of the suspension, to dilute or to adjust pH or ionic strength, this can affect to the flocculation process. However, it is not necessary to manipulate the suspension before using of this methodology.

The study of the flocculation kinetics requires a technique able to measure on real time. Many of this kind of techniques are based on measuring turbidity or on the image analysis. These techniques detect or measure the intensity of the light that passes through the suspension or that is slightly deviated by the particles, because the intensity of the reflected light would be too low. However, these techniques are useful only if the suspension is diluted enough to allow the pass of the light through it, an example of these techniques is the dispersion photometric analyzer. Furthermore, the use of these techniques implies to assume that the turbidity or the colour of the suspension does not change or to assume that the particles are spheres. This introduces an error; because the turbidity often decreases during the flocculation process, the colour can change and the particles are not always spheres.

Using this methodology does not require diluting the sample neither assuming any particle shape. It is not necessary to assume that the turbidity and the colour of the suspension are constant during the flocculation process. Therefore, it eliminates these error sources. Therefore, this methodology is applicable in many different processes involving a change in the size of the particles, or droplets of the dispersed phase (emulsion) by aggregation of the same or dispersion of the aggregates.

|

How does it work |

Methodology to study flocculation process.

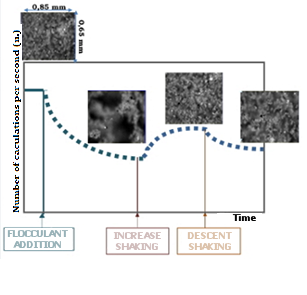

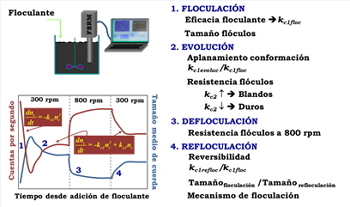

The study, control and optimization of the flocculation or coagulation process is carried out by monitoring the evolution of the particles chord size distribution in real time. This distribution is obtained by a focused beam reflectance measurement technique.

This distribution contains information about the size and concentration of particles, whose variation is inherent to the flocculation process with independence to the mechanism through which this process takes place.

This methodology allows determining the optimal dosage of flocculant, to study the kinetics of the flocculation process, as well as those of the flock breakage (deflocculation) and reflocculation processes. From these studies, it is possible to determine flock properties and to propose the flocculation mechanisms model that explains the flocculant behaviour.

The measurement technique used by the developed methodology consists of a commercial Mettler Toledo equipment with a probe, which is introduced in the suspension or in the pipe, and an electronic box with a detector.

A computer system controls the equipment and receives the data. This equipment is provided with a laser diode that generates a laser beam which is split in different parallel beams. These beams are focused in a point (focal point) on the external surface of the sapphire probe window (sited in the extreme of the probe that is introduced on the suspension) through a rotating lens. The focal point describes a circular path at high speed as a result of the rotation of the lens. When a particle intercepts the focal point path, light reflected is conducted to the detector, which receives light pulses, whose duration is proportional to the particle chord length.

The equipment can measure thousands of particles per second and obtain a chord length distribution, representative of the particle population. The evolution of this distribution characterizes to the flocculation process.

|

Advantages |

This methodology allows the study of flocculation processes faster and more efficiently, thus reducing the costs of the research.

The results provided allow optimizing the processes of flocculation or coagulation; it can be used for the selection of flocculant to use and optimization of its dose. This reduces operating costs, avoiding the use of excessive doses of flocculant, and maximizing their effectiveness.

Optimizing the flocculant dose minimizes its concentration in the effluents and in the product, reducing the inconveniences that it might cause.

When this methodology is used to control flocculation process, one can detect any disturbance in the process before it affects production and thus it is possible to carry out the appropriate action more effectively.

|

Where has it been developed |

The research group that performs this offer carries out its work in the Department of Chemical Engineering, Faculty of Chemistry and it is a very active group. They are specialist in the study of the behavior of colloidal systems and processes involving the aggregation of particles, retention and drainage.

The experience of the research group is more than two decades, during which it has participated in many research projects, especially at international level, but it has participated in Spanish projects too.

In addition, the research group has collaborated with different companies, implementing the methodology presented as part of a control loop, solving the problems and issues raised by the companies and increasing the knowledge on the processes of flocculation of the research staff of these companies.

|

And also |

The incorporation of this methodology is very interesting for all those industrial plants of any sector, size and country, in which a process involving particle aggregation takes place, especially if this is a process of flocculation or coagulation. For example it is applicable in: paper industry, water treatment, recovery of metals, sludge thickening, etc. It has also been used to study emulsion destabilization processes and to optimize heterogeneous reactions.

It is also very interesting its use by research centers who wish to study the behavior of suspensions and emulsions, the effectiveness of flocculants or coagulants or the effects of additives on the processes of flocculation or coagulation. It can be a very powerful tool to optimize the efficiency of the flocculant, determining the best way to use and the optimal dose not only in order to maximize the degree of flocculation, but also when flocs with certain properties are required.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

Carlos Negro Álvarez: cnegro@quim.ucm.es

Department: Chemical Engineering

Faculty: Chemical Sciences