BIOSENSORS, BIOREACTORS AND DRUG VEHICLES FROM ENZYMES AND ACTIVE PRINCIPLES FIXED IN MICROGELS AND HYBRID NANOPARTICLES

|

Description |

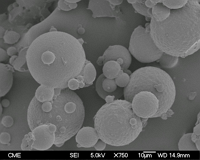

Magnesium polyacrylate microgels obtained by the concentrated emulsion polymerization method and loaded with glucose oxidase.

The gelled systems are of interest in the biomedical industry for the preparation of soft products which can be both external and internal. Examples of external use could be biosensors and bioreactors, creams and gels for cosmetics, etc., while internal use could be the encapsulation of drugs for oral dispensing or in sera. We can prepare gels, with great variety of polymers. By varying the concentration of crosslinker the pore size of these materials and the diffusion of substrates can be controlled through the polymer matrix.

The use of polymeric particles (micro- and nano-gel type) allows to obtain systems with a high surface-to-volume ratio where enzymes that can react with a substrate can be bound or trapped. These systems are subsequently recovered and reused because the enzyme is protected by the polymer matrix, preserving its activity for long periods of time. While several immobilization techniques have been described in recent years, the polymerization method from concentrated emulsions is suitable for a wide variety of enzymes because of their high encapsulation performance. This method consists of making an emulsion with an aqueous phase greater than 75% of the total volume of the emulsion where the dispersed droplets form polyhedral structures separated by a small oil phase film. Polymerization takes place inside these polyhedral structures by adding the initiating agent, encapsulating during this process any enzyme that had previously been dissolved in the aqueous phase.

The use of polymeric particles (micro- and nano-gel type) allows to obtain systems with a high surface-to-volume ratio where enzymes that can react with a substrate can be bound or trapped. These systems are subsequently recovered and reused because the enzyme is protected by the polymer matrix, preserving its activity for long periods of time. While several immobilization techniques have been described in recent years, the polymerization method from concentrated emulsions is suitable for a wide variety of enzymes because of their high encapsulation performance. This method consists of making an emulsion with an aqueous phase greater than 75% of the total volume of the emulsion where the dispersed droplets form polyhedral structures separated by a small oil phase film. Polymerization takes place inside these polyhedral structures by adding the initiating agent, encapsulating during this process any enzyme that had previously been dissolved in the aqueous phase.

|

How does it work |

1. Synthesis of microgels, nanogels and polymer nanoparticles. I) Preparation of monodispersed micro and nanogels by the radical polymerization method in aqueous solution of N-isopropylacrylamide ii) Preparation of polydisperse latex microparticles by the concentrated emulsion polymerization method using a wide variety of polymers iii) Use of techniques for determining the size and structure of the synthesized particles.

2. Synthesis of inorganic nanoparticles. Several methods are used to prepare nanoparticles: i) with magnetic properties such as Fe2O3 and Fe3O4; Ii) with optical properties such as Au and Ag nanocrystals. And iii) with up-conversion properties of infrared photons to visible and ultraviolet photons such as NaYF4: Yb, Er, also NaYF4: Yb, Tm and NaYF4: Yb, Tm @ SiO2 nanocrystals; iv) easily functionalized as SiO2.

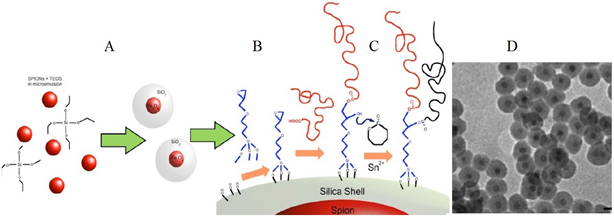

3. Synthesis of multi-response hybrid nanoparticles with core / shell structure. The inorganic nanoparticles mentioned above are used as cores and coated with a polymeric or gel shell. The resulting particles combine the properties of the core material and the crust material. For example, magnetic nanoparticles coated with a thermosensitive gel result in a system that is both magnetic and can be swollen and deflated following the pattern marked by the gel of the shell.

4. Characterization of micro and nanoparticles. Different techniques are used for the characterization and determination of the size and structure of the synthesized particles.

5. Immobilization of enzymes and active principles in micro and nanogels and in micro and hybrid nanoparticles. For the immobilization of enzymes and / or active principles in micro and nanogels the concentrated emulsion polymerization method is used which has a high performance of enzymatic immobilization. Methods are also available for the immobilization of enzymes and active principles on the surface of inorganic and hybrid nanoparticles and specific techniques have been developed for particular cases. For example, NaYF4:Yb, Tm@SiO2 nanoparticles have been coated with a single-stranded DNA layer to make a specific DNA sensor.

6. Functionalization of surfaces. We have developed a method that allows us to coat inorganic nanoparticles with silica covers of a thickness that can be controlled up to the nanometer. The silica coating allows the surface to be easily functionalized allowing covalent attachment of enzymes and active ingredients.

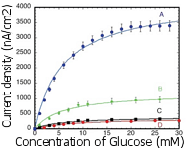

7. Manufacture of sensors and biosensors. The immobilization of redox enzymes in microgels allows us to use this new material as a biological component of very specific amperometric biosensors. For example, if the immobilized enzyme is glucose oxidase, we can manufacture glucose sensors and microsensors. We can also use properties such as fluorescence damping by certain substances to make optical sensors.

Scheme of the route followed to obtain magnetic nanoparticles with polymer coating. A) Synthesis of silica coated magnetic nanoparticles using the inverse microemulsion method. B) Functionalization of the silica surface. C) PEG bonding and PCL polymerization. D) Resultant nanoparticles with magnetic core, silica coating and polymer film (PEG and PCL) on the outside.

|

Advantages |

Response of a glucose biosensor based on microgels where glucose oxidase has been immobilized.

The profitability of obtaining stable, homogeneous and controlled solubility biomedical application systems in aqueous media allows:

The reduction of production costs by:

1) Active principles that ensure bioavailability with long shelf life.

2) The low environmental impact due to the use of biocompatible and biodegradable products.

3) The recovery and reuse of some of these systems based on micro-nanoparticles with magnetic properties.

In relation to distribution:

1) The ease of handling and application.

2) The ease of storage.

3) The positive impact on a high percentage of the population.

|

Where has it been developed |

The group of Bioactive Nanostructured Materials of the Department of Physical and Pharmaceutical Chemistry of the Faculty of Pharmacy has been working on problems related to the structure, characterization and properties of colloidal systems and polymers of biomedical interest for over ten years. We have developed methods for obtaining organic, inorganic and hybrid particles of low polydispersity and sizes that can vary between 5 nm and 1000μm.

|

And also |

The research group has experience in collaborating with private companies in the polymer, biomaterials and dental materials industry, having obtained the following patents in this field:

Stable biocompatible microgels for enzyme immobilization and their use in amperometric biosensors.

Polymeric microgel particles with immobilized glucose oxidase and their use as a glucose biosensor.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researchers |

Enrique López Cabarcos: cabarcos@ucm.es

Jorge Rubio Retama: bjrubio@farm.ucm.es

Marco Laurenti: mlaurent@ucm.es

Department: Physical and Pharmaceutical Chemistry

Faculty: Pharmacy