Thermal spray Al-based coatings

Protective coatings are one of the most effective ways for corrosion control of magnesium alloys. Coating for corrosion protection must be uniform, well adhered to the substrate and pore free, thus, acting as an efficient barrier between the base alloy substrate and the environment. Among the available surface engineering techniques, thermal spray technology allows the deposition of a wide range of functional coatings on many different substrates designed for specific environments. The advantages include the ability to apply a coating to a substrate without significantly heating it, and the possibility to repair damaged coatings without changing the properties or dimensions of the component. Some disadvantages are the difficulty to coat holes and deep recesses of the working piece due to the line-of-sight nature of these deposition processes and application of post-treatments, such as sealing, reheating and mechanical finishing, when improved corrosion resistance and smooth surfaces are required.

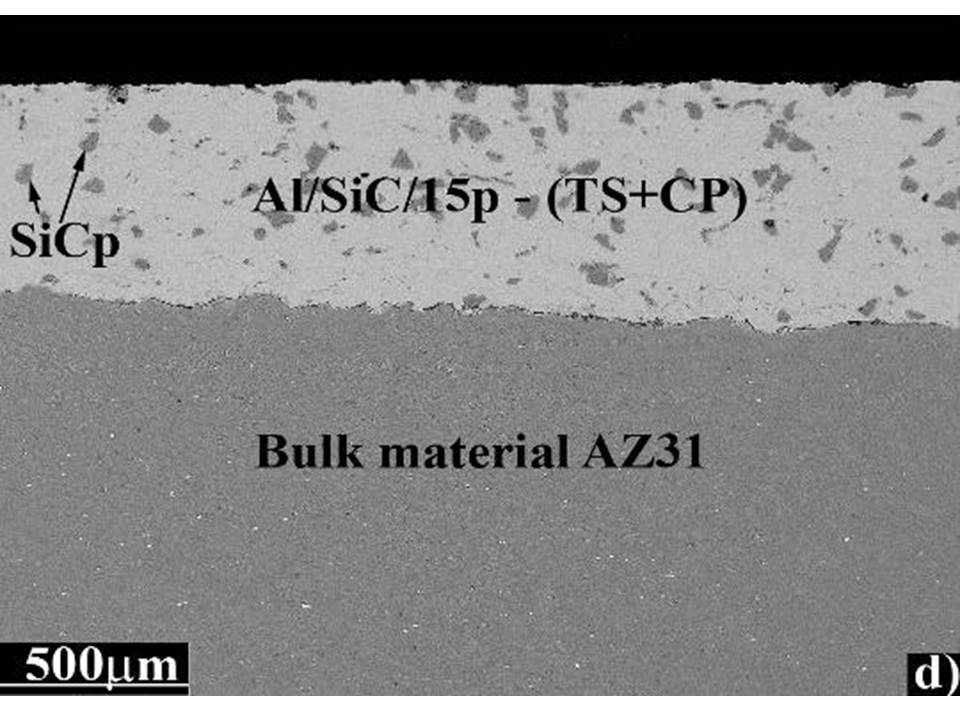

The research line is focused on the fabrication of coatings based on Al/SiC composites by thermal spray processes, which is of great interest due to their excellent wear resistance and easy regulation of the volume fraction of reinforcement phase in the coating.