Semisolid light alloys and composites

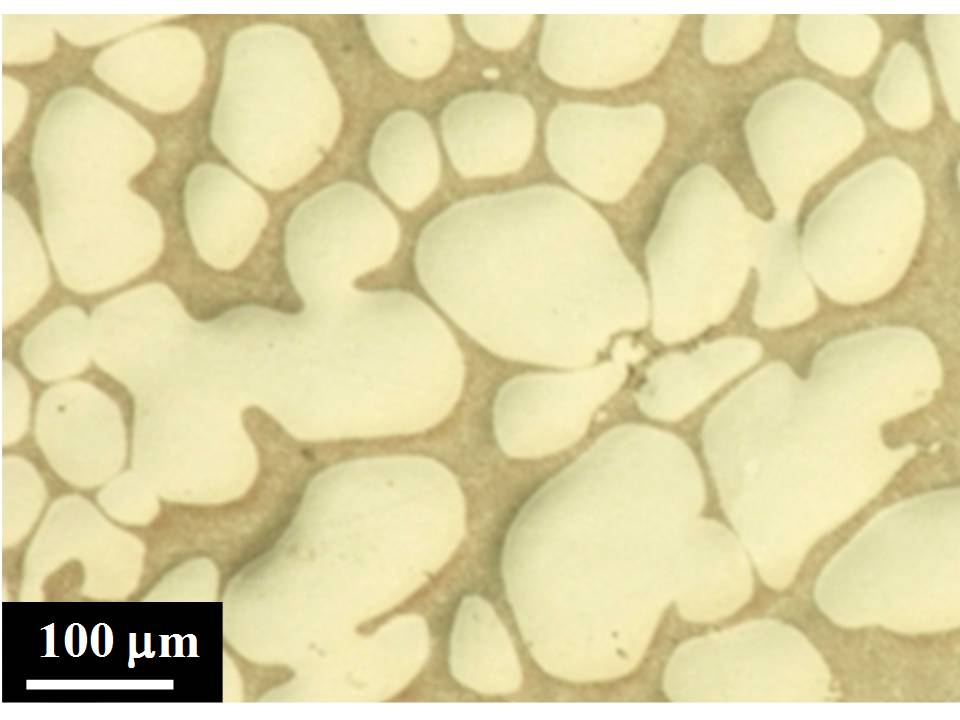

The introduction of semisolid metal (SSM) processing in the early 70s has enabled the development of new industrial processes that substantially improve the main disadvantages of conventional casting alloys. SSM processing involves semisolid slurries with non-dendritic solid particles dispersed in a liquid matrix resulting in internal structures and mechanical properties quite different from those obtained by conventional forming technologies which use either solid or liquid metals as starting materials. Thus, SSM processing is able to produce homogenous globular microstructures where both, chemical and mechanical properties, are considerably improved compared with the corresponding dendritic alloys obtained by conventional casting. Other advantages of SSM methods over conventional manufacturing processes include the reduction of the incorporation of gas into the work piece, the possibility of using molds with sections up to 1 mm (commonly used in complex components in the automotive industry), lower mold thermal fatigue and lower porosity. Therefore, from an economic point of view, considering the short duration of production cycles, longer life of molds, lower machining requirements and the use of less expensive heat treatments, it is expected that the processes via semisolid routes will be commonly used in the transport industry.

The goal of this research line is to develop aluminium and magnesium-based materials (alloys and composites) manufactured by SSM processing, more specifically by Rheocasting.