Metal matrix composites

In recent years the aerospace, military and automotive industries have been promoting the technological development of composite materials to achieve good mechanical strength/density and stiffness/density ratios. One of the main obstacles to the use of MMCs is the influence of reinforcement on corrosion resistance. This is particularly important in aluminium alloy based composites, where a protective oxide film imparts corrosion resistance. The addition of a reinforcing phase could lead to further discontinuities in the film, increasing the number of sites where corrosion can be initiated and rendering the composite liable to severe attack. Commonly, the reinforcement used in metal matrix composites (MMCs) is silicon carbide (SiCp) with a particle volume fraction between 10 and 30%, which gives higher mechanical properties than unreinforced alloys but, normally, worse corrosion resistance in marine environments.

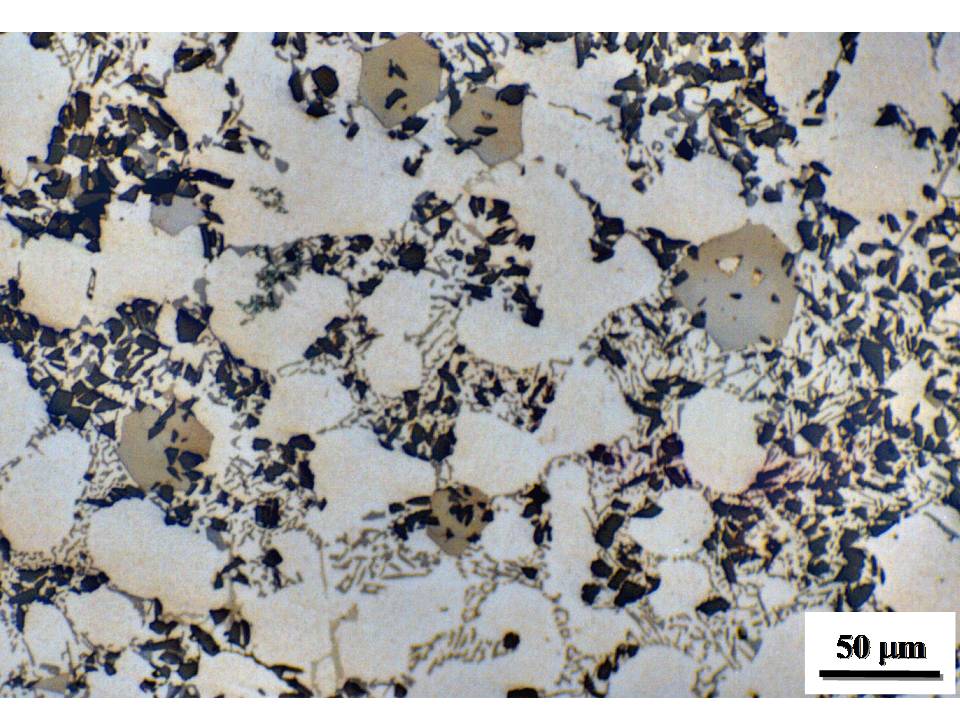

The goal of the research line is to study the influence of reinforcement proportion and matrix composition on the corrosion and oxidation behavior of A3xx/SiC composite materials.