Bioactive treatments for Ti and Mg alloys

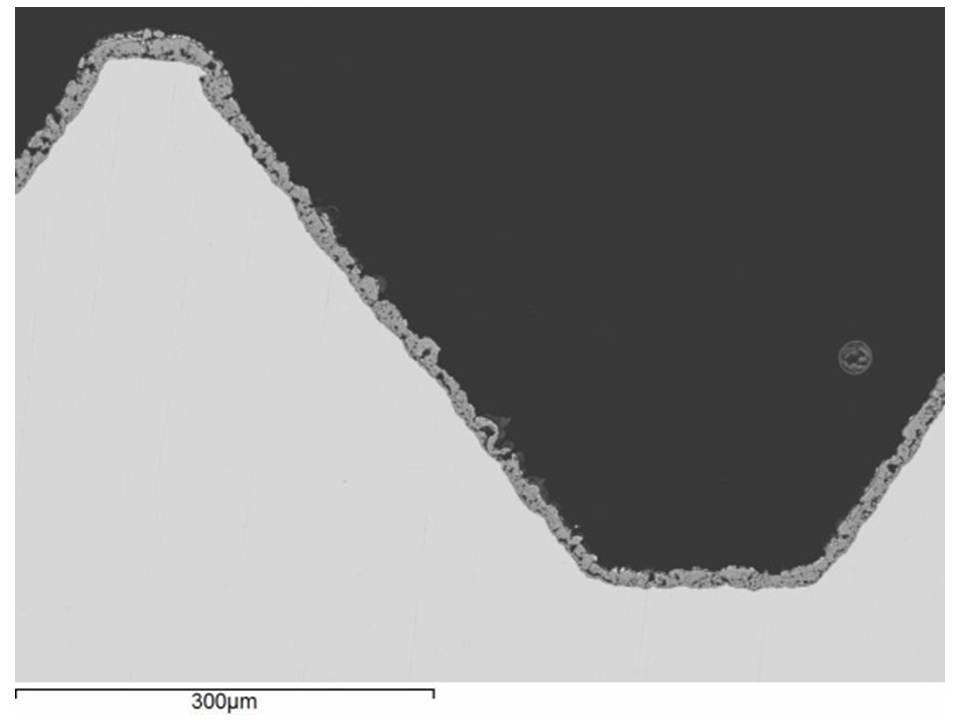

Plasma Electrolytic Oxidation (PEO) is used for generation of biocompatible surface coatings on dental and orthopaedic implants and prosthesis. Compared with conventional surface modification techniques, such as chemical treatment, machining, thermal o plasma spraying and anodizing it offers a series of advantages which encompass a great durability, wear resistance, excellent coating/substrate adhesion and osseointegration, the latter due to a porous morphology of the coatings. Our research focuses on modification of the PEO coating composition via controlled incorporation of calcium and phosphorous in ratios corresponding to that of the natural bone hydroxypaptite, as well as incorporation of other bioactive elements such as silicon or magnesium, which facilitate osseoinduction, and fluorine, which provide an implant surface with antibacterial properties. The biocompatibility of biomedical alloys is determined to a great extent, among other factors, by their capacity of minimal metal ion liberation into a physiological media. Our studies in this area include understanding of the short term and long term corrosion behaviour, and hence the prospects of the service life, of the developed bioactive materials in a range of simulated conditions of human body (e.g. simulated body fluid, artificial saliva) under the influence of different critical factors, such as presence of proteins, variation of pH due to inflammatory processes, presence of fluoride ions in oral environment, introduced through use of oral hygiene products.

Another line of our research concerns with development of biodegradable implants based on magnesium alloys for fracture and trauma treatments; such implants eliminate the necessity of a second surgery after the healing is complete in order to remove the orthopaedic plates and screws. We study the effect of bioactive PEO surface treatments on degradation of the implants in vitro simulated human body environments in order to achieve a reliably controlled corrosion rate.